For the past quarter of a century, underbalanced drilling (UBD) has been a niche technology known to many and practiced by few. It has seen acceptance in the North Sea, where UBD is used to drill through depleted reservoirs. In the Middle East and North Africa, it has been recognized as the only economic way to reach total depth through ultrahard carbonates.

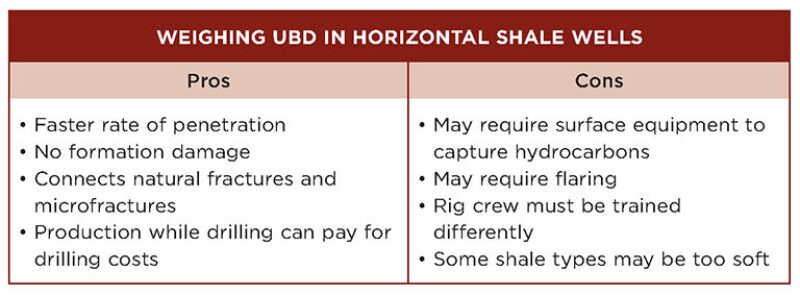

And in recent years, UBD has started to show promise as a way to drill horizontal wells in tight rock and shale plays in the United States. However, the technology has not reached full acceptance. Part of the issue is that the drivers behind UBD’s use have been as heterogeneous as the unconventional formations that companies are using it in.

In heavily fractured formations, users say the underbalanced method makes horizontal drilling easier and reduces mud costs by eliminating loss of circulation problems. This also tends to result in less rig time per well as it increases the rate of penetration (ROP). Rather than use UBD in the production section, some unconventional operators only use it for tophole drilling and then go overbalanced before reaching the reservoir. In optimal cases where UBD is used in the pay zone, enough oil can be produced and sold while drilling underbalanced that it can cover the entire cost of the drilling operation and then some.

Shell has put its full weight behind the technology after using it to reduce drilling costs and nonproductive time (NPT) during the exploration and appraisal phases of all of its unconventional programs, which span the world from China to Canada, said Keith Smelker, a well engineer at Shell.

“The reason why leadership is very bullish on the technology is because we have seen a lot of performance improvements from it,” he said. Those improvements include speeding up exploration drilling in some areas by as many as 15 days.

Before starting each of its unconventional programs, Shell engineers evaluate the applicability of going underbalanced and more often than not, they decide to do so. Smelker estimated that the company used UBD on as much as 85% of the unconventional wells it drilled last year.

In the Permian Basin of Texas, the underbalanced method is now being used to unlock unconventional underpressurized reservoirs. An independent drilling consultant working on UBD projects there, who asked that his name not be used, said some wells drilled into underpressurized reservoirs are showing significantly better production curves than wells drilled into overpressurized reservoirs.

In the best cases, there is little to no decline a year on, and in others the decline rate is averaging around 10% a year. This compares very favorably with a typical shale well decline rate that can be as steep as 80% in the first year. “That opens a lot of doors,” the consultant said. “If you learn how to drill them with this underbalanced method then you will have that longer-term production.”

As compelling as they are, these examples remain on the edge of the business as UBD is currently the least used method in the unconventional industry. Since the earliest days of the shale revolution, overbalanced drilling (OBD) has remained the chief method used by producers to drill their horizontal wells. Coming in at second and growing in popularity is managed pressure drilling (MPD).

Jim Hughes, cofounder of UBD SunStone Technologies and former chief executive officer of SunTerra Well Services, said he thinks the industry has largely overlooked the potential that UBD has to offer compared with the other drilling methods and hydraulic fracturing.

At SunTerra, he worked on several projects including some in the Buda Limestone of south Texas, an unconventional tight oil formation, where going underbalanced has resulted in wells that do not require hydraulic fracturing and cost between USD 3 million and USD 4 million, yet are on par with some of the best hydraulically fractured wells in the nearby Eagle Ford Shale that cost between USD 6 million and USD 8.5 million. For this reason, UBD is becoming the standard completion procedure for developing the Buda Limestone.

However, Hughes said the industry’s long tradition of equating change with risk is keeping operators from repeating the Buda Limestone experience in other formations. “It takes a learning curve and most people are not willing to do that,” he said. “But with prices down to USD 50 a barrel, maybe it is time to think of a different way.”

Reducing Formation Damage

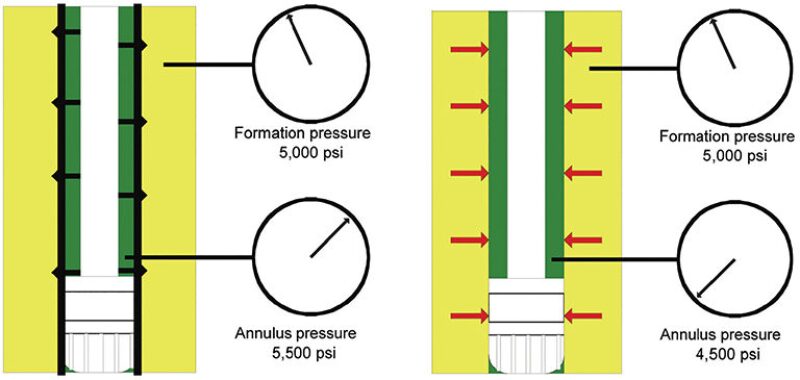

The difference between the three drilling methods comes down to how the forces of nature are controlled. In OBD and MPD, the objective is to maintain a higher pressure inside the wellbore than the pore pressure exerted by the rock formation. This is done largely to prevent influxes of hydrocarbons, or kicks, from disrupting drilling or causing well control problems. MPD uses equipment to fine-tune the wellbore pressure to what some people call, “at balance” drilling, but by its definition, MPD does not allow for influxes.

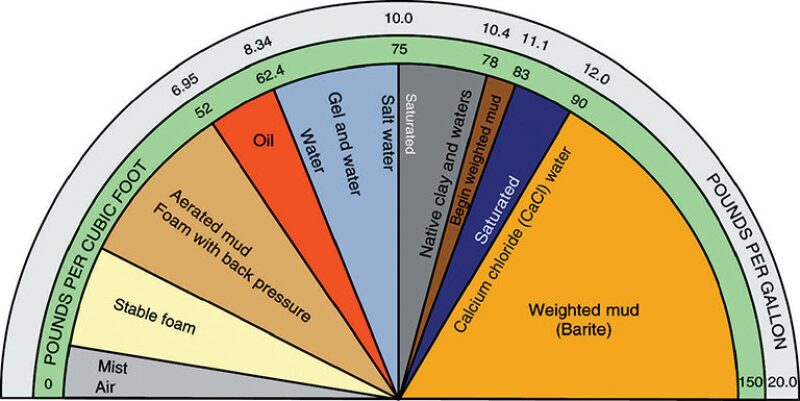

In UBD operations, things are a bit different on the surface and much different inside the wellbore. On the rig, standard equipment includes a rotating control device, a choke, a mud gas separator (commonly called a gas buster), and production systems coupled with a flare to handle gas and oil coming up the wellbore. Downhole, instead of heavy drilling fluids and muds, a light mineral oil, nitrogen foam, and sometimes compressed air are used to exert a lower pressure on the formation than the pressure coming out of it. So instead of preventing influxes, UBD encourages them.

One of the key benefits of this approach is that it results in little to no formation damage, or skin damage, thus leaving the rock in a state that allows oil and gas to flow unimpeded. This is possible only through UBD because the pressure is not forcing drilling fluids, fines, clays, or cuttings into the rock matrix. The Canadian pilot programs that were credited with modernizing underbalanced technology in the late 1980s were driven by this need as their target formations were known for being very sensitive to skin damage.

This is also one of the main reasons underbalanced wells in the Permian Basin are said to be quality producers. The companies that have adopted UBD there have started drilling infill underbalanced wells next to overbalanced wells from the same pad sites. Because the reservoirs are underpressurized, artificial lift systems are required to bring the oil to the surface at the onset of production. Although it adds an extra step of planning, the operator has found a whole new set of profitable horizons that otherwise were not on the table.

In another example, UBD is being used to drill wells in depleted fields where hundreds of legacy stripper wells are producing as little as 1 B/D. To the drilling consultant working in the Permian Basin, the reduction in costs that operators have recently negotiated with service companies and suppliers, coupled with the new opportunities presented through UBD, means the capital cost of some shale wells has dropped from USD 7 million to around USD 3.5 million. “With all the technology we have, we can do just as much or more development at USD 40 oil,” he said.

The Shell Experience

Shell is using the underbalanced method to efficiently access tight reservoirs using slim-hole well plans. In its UBD operations, Smelker said the company uses a choke to apply backpressure that enables the rig to restrict and control influxes to a level that the well design and surface equipment can safely handle. “That in turn reduces our casing strings, increases ROP, and in some cases, it will reduce NPT,” he said.

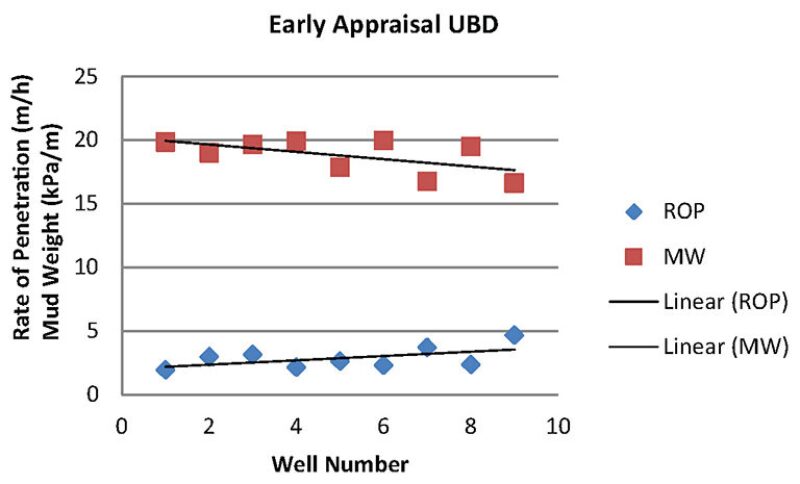

Last year in the Sichuan Basin of China, one of the country’s most active unconventional areas, Shell completed a nine-well UBD program with technical expertise provided via its real-time monitoring operations center in Houston. This setup allowed the Chinese team to overcome its inexperience in UBD operations and on the final well, it had reduced its mud weight by 25%, significantly increased ROP, and eliminated NPT caused by kicks.

With Shell’s closed system, the UBD choke allows the rig to quickly detect kicks and react to them. This method applies pressure instead of increasing the mud weight, which reduces the recovery time before drilling can begin again, and saves on mud costs. This may sound like MPD, but Smelker explained that in this instance, the wells are planned to be drilled with influxes throughout the target formation. Using the applied backpressure technique, Shell has shaved days and weeks off rig time in other areas as well.

UBD has also allowed the company’s engineers to quickly acquire learnings ahead of the development phase of each field. “What we have seen is that if we start early in these projects [with UBD], then we can understand what the wells need early on in the life cycle,” such as mud weight for subsequent wells and surface equipment, he said.

The applied-backpressure method is a low-cost UBD option, but not the lowest. Smelker said while using a choke to apply pressure adds cost, it helps lower risk and optimizes drilling. One added advantage of going underbalanced, he noted, is that in certain circumstances it is possible to see where there is more deliverability in the formation.

Smelker said wells that were “more willing to flow” during drilling have tended to be better producing. This is not always the case though, as Shell has learned that fracture designs also play a significant role in stimulating the reservoir, he said.

Producing While Drilling

Maurizio Arnone, a well engineering manager at Weatherford with experience using UBD in the Middle East and North Africa, has recently taken his talents to south Texas, where the technology has less of a track record. Back in Africa and the Middle East, he had spent years working on tight, low-permeability carbonate formations with natural fractures, all of which presented significant problems for using OBD in long horizontal wells.

“When you are drilling a horizontal well where you want to penetrate the reservoir for 5,000 or 7,000 ft, and your ROP is maybe 1 to 3 ft per hour, you are going to spend months doing that,” with the overbalanced method, he said.

When the companies facing such an intractable challenge switched to UBD, they saw immediate improvements in ROP of close to four times, partly because the bottomhole pressure compacting the area around the drill bit was eliminated. At a ROP of 12 ft/hr, Arnone said the life of the drill bits improved, fewer trips out of the well were required, and when the operators intercepted fractures, they were able to produce oil and gas while drilling.

These jobs took place when oil was selling below current low prices and yet the economics were still strong. Arnone is now working on Weatherford’s underbalanced projects in the Buda Limestone, which he said shares geological characteristics and some of the benefits of the operations he worked in half a world away. “There are some wells that while drilling are giving you 1,000 B/D of light crude,” he said.

Wells that produce like that pay for themselves quickly, but this blue sky scenario does not always present itself. “We also have seen some wells in the Buda where simply no production was seen while drilling,” he said. “That is in a different way a benefit to the operator as well. He can take one of two choices: go and frac, or abandon.”

Hughes who has spent several years working on various projects in the Buda Limestone, said the caveat with producing while drilling is that the operator must be prepared to handle hundreds or thousands of barrels a day and similar proportions of gas. To make this possible, a separation system is used to handle 40,000 B/D of oil or 100 MMcf/D of gas.

Like other unconventional formations, Hughes said the Buda Limestone is known for being naturally fractured and when some of his clients tried to develop it using OBD, they experienced fluid losses, followed by a gas kick. When that happened, it would take the operator 2 to 3 days to rebuild their mud system at a cost of around USD 1 million. “We came in and showed them that the next time you take a kick, don’t worry about it,” he said. “Just let it flow through our system and into our separator and keep on drilling.”

After applying this UBD system, Hughes said one of the first wells flowed with 5,000 B/D of oil during drilling, compared with the 500 B/D to 800 B/D that the operators were producing after hydraulically fracturing the other wells. “The issue for the company man was how to handle that much oil in a drilling operation,” which Hughes said required 10 “frac tanks” to store the oil and the roads to the drilling site must be in good enough condition to handle trucks moving the product offsite 24 hours a day.

SunTerra ended up drilling more than 20 wells for that operator, many of which initially produced between 1,000 B/D and 5,000 B/D of oil. Hughes said the decline curves of the wells were similar to overbalanced wells, but because some of the initial production rates were 10-fold higher, it is easy to realize the positive gain being made in terms of ultimate recovery.

One key area of savings in using UBD is that the operator no longer had to spend the USD 3 million that it was paying for hydraulic fracturing to stimulate the reservoir, nor did it have to wait up to 3 months for the crews to arrive to do the job.

Is Shale too Soft?

Understanding where UBD is applicable is important to gauging its potential. Because there is no outward pressure or chemical reaction taking place that makes the borehole stronger, the formation must be naturally stable to keeping it from caving in or sloughing.

“Shales are about 80% of what you drill through, and they are the material, almost uniquely, that leads to borehole instability problems,” said Maurice Dusseault, a geological engineering professor at the University of Waterloo, who has studied UBD. “If you start to have sloughing or a borehole instability issue, it almost always is associated with shale.”

He said one of the best ways to avoid such problems with shale and swelling shale, in particular, which quickly absorbs drilling fluid, is to use UBD. However, his research suggests that many of the coastal shale formations may be too soft. Others closer to the Rocky Mountains may have characteristics that would result in big chunks of rock falling into the wellbore during drilling. But in most other formations found in the interior US, he said the conditions appear to be just right.

Because the direction of flux is coming into the wellbore, shale deterioration is significantly reduced in a UBD operation. And because a UBD operation usually moves faster than an OBD operation, Dusseault explained that there is simply less time to cause damage.

“If you can drill three or four times faster, then you are exposing your shale to this environment for 5 days instead of 15 or 20 days,” he said. “And we know that shale has a time-dependent behavior; the longer you expose it, the more trouble you are going to get into.”

To Frac or Not to Frac?

The fact that the operator did not need to hydraulically fracture its Buda Limestone wells convinced Hughes that there must be other formations where production can be achieved without such expensive stimulation. A trained geologist with 35 years of experience in the industry, Hughes believes that the widespread use of OBD in other unconventional formations has prevented companies from realizing the positive impact that small natural fractures called microfractures have on production.

“They are invisible to the naked eye yet [can] have permeability on the order of 50 darcies, but they are easily plugged by OBD fluid,” he said. “If the permeability is there, and now we have horizontal drilling to connect these fractures, whereas vertical drilling could not do that, the simple trick is to drill laterally across fractures without plugging them up.”

Arnone said he, too, has seen evidence of production-aiding microfractures and agrees that they are likely more common than the industry is aware of. However, he and others think that the majority of unconventional formations will still require hydraulic fracturing to achieve optimal production from a horizontal well, no matter what drilling method is used.

“If there are natural microfractures in that very tight formation, like Buda and Haynesville, yes, underbalanced will help you because it means you are going to produce directly from them,” Arnone said. “If it is a formation that is very tight and there are no natural fractures, doing underbalanced drilling is only going to help you with the ROP.”

Hughes’ point of view that UBD can be used as an alternative to fracturing has led him to serve as an expert witness for cities whose citizens voted to ban hydraulic fracturing in Texas and Colorado. However, he noted that UBD does not preclude a company from eventually fracturing its well. “In other words, you can drill an underbalanced horizontal well and if you do not like what you see productionwise, you can kill the well, run pipe, and frack it,” he said.

While the science on the relationship between microfractures and productivity is still inconclusive, Weatherford is looking into the matter. Arnone said that going underbalanced may be the only way to detect microfractures that are large enough to aid in the production of oil and gas, since other technologies, specifically downhole logs, have not been adapted to identify them.

Unless the area is very tectonic, which would indicate that there may be natural fractures all over, Arnone said currently the only way to know for sure is to drill. “If there are chances that formation has some kind of natural fractures or microfractures, if we go UBD, it will allow you to identify where they are and can tell you if you need to do a post-frac or not,” he said.

To learn more, Weatherford is working with an operator in the Buda Limestone to characterize fracture prevalence based on seismic data taken from the surface and from inside wells. Arnone said the plan is to correlate the data to see if there is a way of detecting small natural fractures, which might help an operator decide if it needs to hydraulically fracture a well before it even begins drilling.

The Operational Obstacle

Robert Ziegler, general manager of drilling engineering at Cairn India, has worked with underbalanced drilling (UBD) for more than 20 years and has been active in educating engineers where it can be applied. Despite the potential of the technology, he said the industry as a whole has never become truly comfortable with it, and may never be.

For many drillers and operators, Ziegler said the idea of allowing hydrocarbons to flow up the wellbore during drilling induces a “cold sweat” and has contributed to a general lack of industry acceptance. “They are very uncomfortable with this,” he said. “‘We do not drill for kicks’ was a very typical argument.”

He explained that much of today’s UBD technology is the product of efforts made by Canadian companies in the late 1980s and early 1990s to tap into horizons that few thought was possible to produce from. It worked; but either through management changes or acquisitions, those projects were not sustained.

Ziegler said the end of those projects left UBD in limbo, and that when considering the future of the technology, the drilling aspect must be separated from the completion and intervention aspects. “One is successful, and the other one still has not had the breakthrough,” he said.

An example he offered of this legacy happened offshore Malaysia where a major operator drilled three underbalanced wells that produced at a rate 10 times higher during drilling than the best wells drilled elsewhere in the field. But then the completions team came in and inadvertently killed the wells by re-entering it in an overbalanced state.

The hard lesson learned was that once a well is drilled underbalanced, in order to take advantage of the lack of formation damage, completions and later-stage well interventions should be done using underbalanced technology. “All of these things have to be done with one thought in mind: ‘I never want to go overbalanced,’” said Ziegler.

However, the integration of life-of-field services for underbalanced wells has never received the industry’s full attention. The solution would require companies to fully understand how to adapt methods and technology to support underbalanced wells, a task that would require a long-term commitment of time and money and one that Ziegler does not see happening any time soon.

“Are we ever going to have a paradigm shift where we are able to do things that are very different, which is underbalanced drilling operations? In the current environment, I do not believe so,” he said. The reason for Ziegler’s pessimism is rooted in the industry’s tendency to focus on near-term economics, not its own engineering capability.

And while he believes there is a slim chance that an industry player will adopt a full underbalanced life cycle concept anytime soon, Zeigler argues that there is a strong business case for UBD to become a reservoir characterization tool. “Especially in tight formations, and here especially in gas, underbalanced drilling can even have a cost benefit compared to an extensive logging program, while providing superior primary, not secondary, information on reservoir content, flow potential, and pressures,” he said.