This paper describes the evaluation of a nanofluid containing nanomaterials with high adsorption capacity used for asphaltene inhibition in the volatile Cupiagua Sur oil field in Colombia. Asphaltene precipitation has been identified as one of the most potentially damaging mechanisms affecting this field’s productivity. The goal of the injection of nanofluids containing nanoparticles of alumina with high surface area is to absorb the asphaltenes and carry them with the condensate, avoiding precipitation near the wellbore.

Introduction

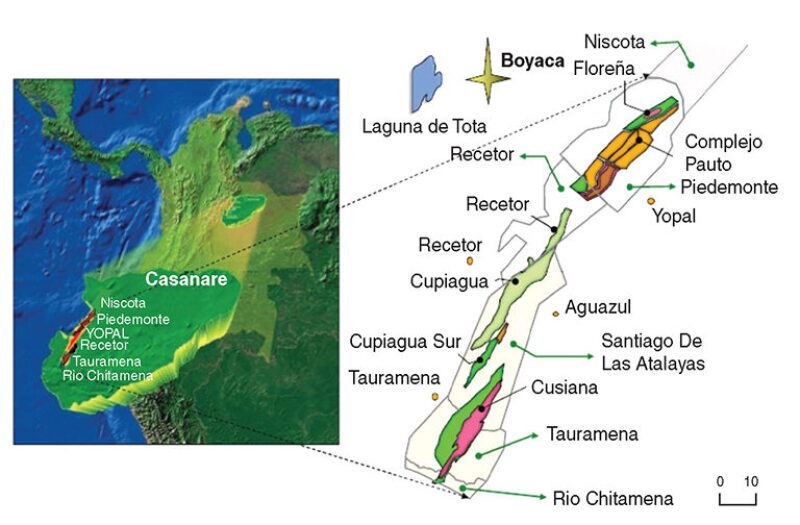

The Cupiagua Sur field is located 110 km northeast of Bogota in the foothills of the Colombian Andes, close to other fields such as Floreña, Pauto, Volcanera, Recetor, Cupiagua, and Cusiana (Fig. 1 above). Despite the fact that Cupiagua Sur is very close to Cupiagua, this reservoir is totally independent and separate. It is a compositional volatile-oil reservoir with an average gravity of 38°API; there is no free-gas cap at initial conditions (for a discussion of asphaltene precipitation in volatile oil, please see the complete paper). The main formations are Mirador and Barco, which are quite similar in terms of petrophysical and fluid properties (average permeability is 21 md, and average porosity is 6.5%).

Cupiagua Sur is a prolific oil field that in 15 years of production has recovered 88 million STB/D gross out of 189 million STB/D originally in place from Mirador and Barco reservoirs in a developed area with four producer and two injector wells.

The current reservoir conditions in this field are highly dependent on the way the reservoir has been produced. The first production well, CPXP1, started producing in March 1998, while the first gas-injector well went into action in January 2000; at that time one volatile well was on production. There are currently six active wells in the field. There are four producers and two gas injectors.

Oil production reached its peak in March 2001 at 41,722 STB/D. The average gas production at that date was 175 MMscf/D. Today, the recovery factors are 48.2% and 29.5% in the Mirador and Barco formations, respectively. There was no production plateau in Cupiagua Sur; instead, a constant decline rate is observed. This indicates the extreme conditions under which the reservoir was depleted, as well as the sources of damage.

In Cupiagua Sur wells, the increase in CO2, compositional changes, pressure drop, and the revaporization caused by gas injection are the main factors favoring asphaltene destabilization and precipitation. Periodic cleaning jobs are performed in those wells by use of a chemical blend composed of an aliphatic/aromatic mix. These stimulation jobs have been effective in increasing oil production. However, the effective life of organic stimulation is very short and the wells need to be stimulated again after a few months. Chemical inhibition jobs also have been performed with polymers that act like resins for the asphaltene-inhibition mechanism.

The method of using nanofluids containing alumina nanoparticles is expected to effectively extend the life of organic stimulations, preventing asphaltene precipitation downhole while maintaining a sufficient residual of nanoparticles within the reservoir. With the implementation of this nanotechnology, it will be possible to compare results between this novel method and the polymer-inhibition method.

Experimental Description

Asphaltene Isolation. The first stage of the study consisted of asphaltene extraction from a sample of oil by use of traditional methodology for asphaltene flocculation (adding n-heptane). The n-heptane/oil mixture was prepared in a ratio of 40:1, and then the mixture was sonicated for 2 hours at 25°C, then put through centrifugation for 2 hours to complete decantation. The precipitate was then filtered through 8-µm Whatman paper and repeatedly washed with n-heptane to obtain a clean leachate. Finally, the filter containing asphaltene cake was dried in a vacuum for 24 hours.

Adsorption Test. A stock solution of 1 g of asphaltenes in 0.5 L of toluene was prepared. Different dilutions were then prepared from this stock solution in order to produce a calibration curve by use of a spectrophotometer measuring runs at a wavelength of 295 nm.

To construct isotherm curves, three different dilutions were prepared with concentrations of 25, 750, and 1,500 ppm and nanoparticles were added at 0.1 mg per 10 mL of solution. The vessels containing the solutions were submitted to a magnetic stirrer for 15 minutes, and allowed to stand for 5 minutes afterward. A sample of the supernatant was then taken, and an absorbance measurement was carried out in the spectrophotometer. This cycle was repeated continuously until two consecutive equal values were achieved, indicating that the equilibrium point had been reached. The time was recorded, and a curve representing adsorption vs. time for the nanomaterial was elaborated.

The nanofluid was prepared using a mixture of solvents as a carrier fluid for alumina nanoparticles. This carrier fluid, or mixture of solvents, needed sufficient viscosity to maintain nanoparticles in suspension and needed low surface tension in order to maintain appropriate dispersion of the nanoparticles. The solvent mixture also required good compatibility with the nanomaterial, avoiding any further reaction that might degrade or otherwise affect the nanoparticles. Aromatic solvents were not included in the nanofluid for environmental reasons. Upon preparation of the nanofluid, effectiveness in a core plug obtained from the Cupiagua Sur field was evaluated.

Coreflooding Test and Results. These tests are fundamental for evaluation of the nanoparticles’ effectiveness for asphaltene inhibition in porous media, and also for determining return permeability in porous media after each flooding-test stage. For the coreflooding procedure used in the field, please see the complete paper.

Changes in oil effective permeability show the alteration of permeability by asphaltene precipitation. After n-heptane injection, without inhibition, asphaltene precipitation creates skin damage greater than 99% if it is compared with the original permeability. After cleanout with an injection of diesel, alcohol, and xylene (DAX), the skin damage was reduced to 37% and, after application of the nanofluid containing nanoparticles for asphaltene inhibition, additional skin-damage reduction to 34% was achieved. Inhibition is proved after application of nanoparticles; the oil effective permeability is maintained for a long time after 50 pore volumes of injected oil. Additionally, the relative permeability to oil visibly increases after application of the fluid containing alumina nanoparticles.

Field Application

For reasons detailed in the complete paper, Well CPSXL4 was the first well selected for testing the new stimulation technology.

Developing a New Technology With Nanoparticles To Inhibit Asphaltene Deposition. Four chemical stimulations were performed in the well. The first one was conducted in January 2004 to attack inorganic deposits; this was followed in April 2006 with an inorganic/organic stimulation.

In January 2011, a selective stimulation was performed in the Barco and Mirador formations; the instantaneous oil-rate increase was 152 BOPD.

The chemical stimulation using inhibition developed with nanoparticles was designed to overcome the main problems associated with the previous inhibition methods. Usually, organic stimulations are performed for periodic cleaning or for removing asphaltene deposits that precipitate in these wells. Management of pressure drop is needed in the field to avoid large pressure drawdowns that accelerate flocculation and precipitation of asphaltenes.

High flow rates and high pressure drops prevent good retention of conventional inhibitors of asphaltene formation. It is expected that asphaltene inhibitors based on nanoparticles such as nanoalumina have greater affinity for the mineral structure of the reservoir rock (stronger adsorption) and can be retained for extended periods.

Stimulation and Inhibition-Job Strategy in the CPSXL4 Cupiagua Sur Well. The overall stimulation job was performed in several stages to ensure the best reservoir conditions for the inhibition treatment.

A pickling job was set to clean the production tubing, and an ethylene-diaminetetraacetic acid treatment was begun to dissolve carbonate scale; an organic treatment stage was intended to dissolve organic scale. The inhibition job in CPSXL4 was carried out in December 2012, pumping 220 bbl of nano-fluid containing alumina nanoparticles and 411 bbl of displacing fluid to reach the desired penetration radius of 7.2 ft. As displacing fluid, the DAX mixture was used.

A coiled-tubing unit was used, and a selective packer was set between the Mirador and Barco formations. The job was performed, pumping fluid at a very low rate and at pressures below the fracture gradient. After 12 hours of soaking time, the well was opened for production at controlled flow rates.

Results

A production well test was performed between each stage to verify well performance.

- The net initial incremental oil rate was 1,280 BOPD.

- A performance increase (American Petroleum Institute scale) was observed, from 40 at the beginning of the stimulation job to 41.5 at the end of the inhibition with nanoparticles.

- Nodal system analysis showed an improvement obtained in inflow performance relationship (skin reduction); also, the vertical lift performance relationship was altered because of the increase in oil production.

- The post-inhibition/post-stimulation production performance has been monitored for almost 8 months; during the last 3 months of that period, production has remained a constant 300 bbl above the baseline.

This article, written by JPT Technology Editor Chris Carpenter, contains highlights of paper OTC 24310, “Application and Evaluation of a Nanofluid Containing Nanoparticles for Asphaltene Inhibition in Well CPSXL4,” by R. Zabala, E. Mora, C. Cespedes, L. Guarin, H. Acuna, and O. Botero, Ecopetrol; J.E. Patino, Petroraza; and F.B. Cortes, Universidad Nacional de Colombia, prepared for the 2013 Offshore Technology Conference Brasil, Rio de Janeiro, 29–31 October. The paper has not been peer reviewed. Copyright 2013 Offshore Technology Conference. Reproduced by permission.