Sometimes a new oil play is discovered by an explorer doing “the right thing for the wrong reason.”

That is how Ken Barbe, one of the founders and managers Manzano LLC, describes the decision to drill one of the first successful wells into a Permian play which is unconventional, but not in the way he and his partner had expected.

The independent company drilled a horizontal well thinking “we were dealing with tight rock that produced limited amounts from vertical wells,” he said. But when they fractured their first horizontal well they found more permeable rock producing a lot of water.

That led to conversations with two other companies pioneering this zone that said it was to be expected.

“We had some conversation with Forge Energy and Walsh Petroleum and they encouraged us to be patient and that we would start seeing an oil cut once we got our pump intake pressure down,” Barbe said. “They were exactly right and we had to change our opinion on how and why the reservoir would work economically.”

The three companies are among a group of independents in West Texas that have shown it is possible to consistently drill and complete wells producing hundreds of barrels a day of good-quality oil from relatively shallow, horizontal wells that require little fracturing.

The method requires a leap of faith and some high-capacity injection wells because those wells initially produce only large quantities of water and continue to do so long enough to make a strong case for plugging and abandoning the hole.

“They always come in at 100% water for a couple of weeks, then they start making a little oil, 1 to 3 B/D, with a peak usually of about 200 and 300 B/D,” said Russell Hall, president of Russell K. Hall and Associates, an engineering consulting firm in Midland, Texas, that is tracking this recent trend.

Unlike wells in high-profile plays such as the Wolfcamp, oil production from these wells declines more slowly so that “a year later it will be 100 to 150 B/D. It is not as steep as we see in shale plays,” Hall said.

About 90% of the wells are successful, but large-scale water-handling capacity is required because the key to this method is reducing pressure in the reservoir by disposing of the water elsewhere. Even when oil production comes on line, about 80% of the output is saltwater.

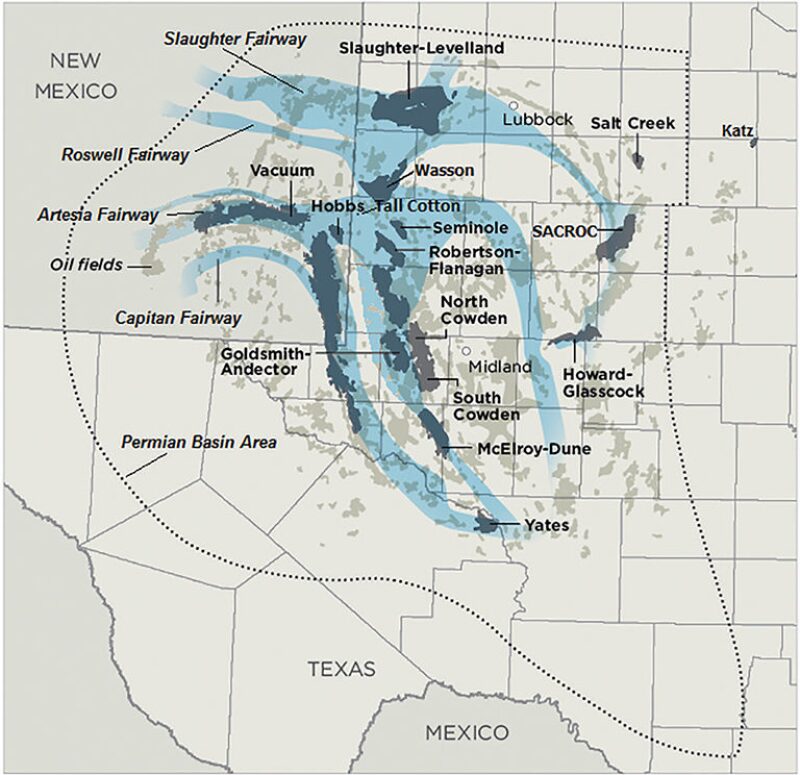

He said there are about 12 small, private companies now drilling in the residual oil zone (ROZ), which is found below the oil/water contact level in conventional reservoirs. The ROZ represents an enormous target. Research work conducted by a group in Midland and backed by the Research Partnership to Secure Energy for America (RPSEA), a nonprofit organization that supports new energy technology, has shown that it is hundreds of feet thick and underlies much of the Permian in West Texas and New Mexico.

While an ancient natural waterflood swept out much of the oil—leaving about as much as would be left after a year of waterflooding in a producing field—that was enough to attract many explorers whose wells produced only water.

Name recognition remains a problem for the play in part because the companies involved are not well-known. At a session on development strategies for the ROZ, a featured topic at the 2016 CO2 and ROZ Conference in Midland in December 2016, nearly all the companies making presentations were small independents, and some were startups, often backed by private equity funds.

The companies involved also cannot agree on a name for the play because of different ideas about how it works. Steve Melzer, a Midland consultant who was the director of the conference, said the name he uses “depends on who I am with.”

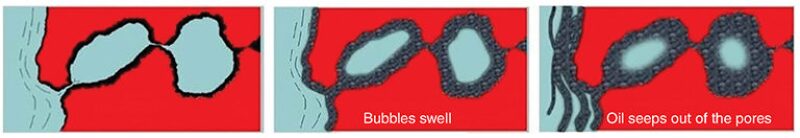

Some call it dewatering because the water is removed by pumping and disposed of in other formations, rather than reinjected. Others call it a depressurizing play because the water removal stimulates production by reducing reservoir pressure to below the bubblepoint—the level where the gas dissolved in the oil escapes from the solution and expands. The escaping gas drives production and increases the relative permeability of the oil within the tight rock, said Hall, who has been running simulations to study the process.

Others see horizontal drilling tapping pockets of oil, or say fracturing is needed to stimulate production along laterals that are typically about 5,000-ft long.

Hall has been closely following this West Texas play since he was hired by a pipeline company to study whether it will yield enough to justify installing lines to serve it.

Production data are limited. The oldest well was drilled 3 years ago. The best analogy is a play that used dewatering to produce gas and gas liquids from the Hunton formation in Oklahoma, said Ben Azar, whose father was a pioneer in the play that dates back to the 1990s.

Azar, co-founder of ROZ Resources, said the depressurizing process can be compared to producing coal-seam gas, where dewatering is also required. “When I have tried to explain the Hunton in simple terms, I have described it as coalbed methane on steroids,” Azar said. “It is the same in that you have to move a lot of water to get the gas out.”

The difference is that in coal-seam gas, reducing the pressure frees gas trapped in the coal—desorption—while in oil, the pressure reduction causes the gas in solution to vaporize and expand, driving liquids production.

When it comes to the details of how the oil and gas got there and why it has remained there, research has led to some unconventional theories.

ROZ researchers have concluded that the rock is oil-wet, with a stronger attraction to oil than normally assumed, allowing an oil saturation level of approximately 35% with variations that do not seem related to porosity, as is commonly thought.

“We have talked to good technical people who looked at us like, ‘You crazy idiots, that is not how the world works,’” Melzer said.

Amazing Patience

The first horizontal ROZ well completed in the Permian was drilled by Walsh Petroleum, Hall said, adding that Manzano Energy was close behind. After that well was drilled, Walsh waited more than 30 days before it started getting significant oil production. “The amazing thing is they had the patience. They did not just abandon it after a week,” he said.

Those explorers were learning from experience like a similar group of independents in the Hunton formation.

In the late 1990s, Altex Resources noticed the benefit of removing water from a reservoir when a well it used to reinject water into a producing formation broke down, forcing the company to pay to haul the water to a disposal well.

“The oil cut went up. That seemed funny, but it was great. That’s no problem. Then they got the disposal well fixed and the oil cut went down and a light bulb goes on,” he said.

That suggested that removing water promoted production, but when the company drilled wells into a nearby dolomite formation, all it got was “a big splash of water and a puff of gas,” Azar said.

Frustrated by those dry holes, his father drilled a horizontal well and began pumping thousands of barrels of water a day and continued to do so for several months until natural gas began showing up in the flow, Azar said.

“We saw gas around the backside (in the casing annulus), the water volumes go down and gas volumes go up. It was totally counterintuitive,” he said. “Over time, the gas got richer and richer,” with more than half in the form of natural gas liquids, which then commanded a premium price.

Ultimately, the play stretched over about five counties in Oklahoma, “but even within the Hunton there was not a whole lot of fanfare about it,” he said.

The plays were always limited to small local operators, in part because big companies had trouble explaining it to investors.

“It is a complicated story to tell to the public markets,” said Azar. There was the awkward question: How does it work? “Originally, we really did not know, but we recognized it was working and continued to drill it.” Over time enough data were gathered that led to a series of SPE papers and a report for RPSEA explaining how depressurizing worked.

Permian Difference

Azar’s company was Brittany Energy, which has since been sold to Hunton Holdings. The play suffered when the value of gas liquids plummeted as production from shale plays glutted the market and water disposal became a a point of contention after a surge in the number of earthquakes in Oklahoma led to disposal-well injection limits.

Now state officials are pointing to the dewatering play in the heart of the area hardest hit by earthquakes as one of the causes of the trouble.

“Production from the Mississippian Limestone and Hunton dewatering play operations within the 15,000‑sq-mi earthquake area of interest has resulted in an unprecedented amount of saltwater” injected into deep disposal wells, said Tim Baker, director of the Oklahoma Corporation Commission Oil and Gas Conservation Division, adding that “there is broad agreement among researchers that disposal of these large amounts of water into the state’s deepest formation (the Arbuckle) can be linked to the high earthquake rate.”

Dewatering in the HuntonAn SPE paper (94347) based on using dewatering to produce oil in the Hunton basin in Oklahoma observed:

|

Two of Brittany’s old wells are now being used by the state to observe pressure changes in that deep formation to help study the issue.

Texas looks like the next frontier. The area covered by the ROZ in the Permian is far larger than the Hunton, it produces quality crude (30 to 36 °API), and water disposal has not been an issue there. Dewatering offers a lower-cost alternative to using enhanced oil recovery (EOR) to produce oil from the ROZ.

Permian operators such as Occidental and Hess have deepened carbon dioxide (CO2) EOR projects to tap the ROZ beneath 16 conventional reservoirs. Kinder Morgan has taken this a step further with its Tall Cotton project that is the first greenfield ROZ project, using CO2 to produce oil in a location with no production above it.

Using alternating carbon dioxide and water injections can produce around 30% of the oil in place in the ROZ. That is several times more than dewatering, which is around 7.5%, Melzer said. Carbon dioxide is able to remove more oil from the oil-wet rock, and works in areas lacking the gassy oil required for depressurization.

Still, dewatering is an attractive alternative because it opens the ROZ to companies that do not have the money, skills, or patience to make a large, long-term commitment to CO2 EOR.

“What is nice about this is we do not have to spend money to put CO2 in ground. You can drill horizontal wells, draw it (pressure) down, and make money. It is not as large an upfront investment,” Hall said.

When talking about this method, Melzer prefers to call it the DUROZ, for “depressurizing the upper ROZ.”

“Upper” is specified because testing has shown the gas content is higher in the oil near the top of the zone, which can be as much as 500-ft thick. That is essential, because the gas coming out of the oil in solution is critical to moving the oil and ensuring that it flows.

The local geology also is important. There are places that cannot be depressurized, because large fractures or highly permeable rock allow large inflows of new water to replace the water as fast as it can be pumped.

There are also locations where well logs show promising levels of oil, but fail to show that the oil cannot be mobilized due to fractures or impermeable areas in the rock, said Mohan Kelkar, a petroleum engineering professor at the University of Tulsa who has written extensively about the Hunton play.

Horizontal drilling is thought to contribute to production by tapping into natural compartments containing oil.

Fracturing is commonly used, though these jobs are small compared to the hydraulic pressure applied to nearby shale formations. Azar points out the ROZ reservoirs are relatively permeable, and even with fracturing, pumping is still required to lower the pressure enough to get the oil flowing.

Because of the large volume of water produced, companies need leases covering large contiguous areas to generate enough production to justify the investment needed in water processing and disposal equipment. Azar said it is important to drill wells that allow pumps to be installed as deeply as possible to speed drainage, resulting in more production sooner.

While the ROZ is hardly an ideal reservoir, Hall described it as fair-quality rock.

A paper on what made dewatering work by three researchers from the University of Tulsa (SPE 94347) does not mention fracturing. It points out that productivity in the play varies widely based on a variety of reservoir factors ranging from oil saturation levels to the amount of gas in the oil.

Greater oil saturation was found in less porous rock, which was less likely to have been swept out by an ancient waterflood that removed much of the oil. Based on data from many wells in a four-county area, the paper concluded that conventional reservoir models did not adequately explain things, such as the declining gas/oil ratio, so they created a model that reflects how the pressure decline affects the output.

Some of those conclusions are challenged by work in the Permian.

“The 20 years of work done characterizing the ROZs beneath the San Andres oil fields has surprisingly shown that the oil saturation of the rock is relatively independent of the porosity of the rock,” Melzer said. Research concluded that the rock became oil-wet late in the process of being turned into dolomite, and microbes may well play a key role.

Hall expects that the Permian operators chasing what looks like a big opportunity on small budgets will cooperate to figure it out. “They are doing a great job of sharing data among themselves. It is among the most transparent projects I have ever seen,” he said, adding, “That certainly improves the learning curve. If you can learn from someone else’s mistakes, you do not make them yourself."

For Further Reading

SPE 94347 Dewatering of Hunton Reservoir: What Makes It Work? by M. Gupta, R. Joshi, and M. Kelkar, University of Tulsa.

SPE 89462 Dewatering in Hunton Reservoir—Drill Vertical or Horizontal Well? by D. Zubarev, S. Patwardhan, M. Kelkar, University of Tulsa; B. Keefer, Marjo Operating Co.

SPE 93963 Changes in Horizontal-Drilling Practices Improve Production From the Hunton Formation: Area Study Comparison by K.L. Booth, Altex Resources Inc.; B. Varcoe, Precision Drilling; and P. Bryden, Altex Resources Inc.