Carbon capture, use, and storage (CCUS) in geological media can be an important means for reducing anthropogenic greenhouse-gas emissions. Several geological settings are appropriate for geological storage of carbon dioxide (CO2), including depleted oil and gas reservoirs, deep brine-saturated formations, CO2-flood enhanced-oil-recovery (EOR) operations, and enhanced coalbed-methane recovery. The US Department of Energy is pursuing a program to demonstrate CCUS technology through its Regional Carbon Sequestration Partnership (RCSP) program.

Introduction

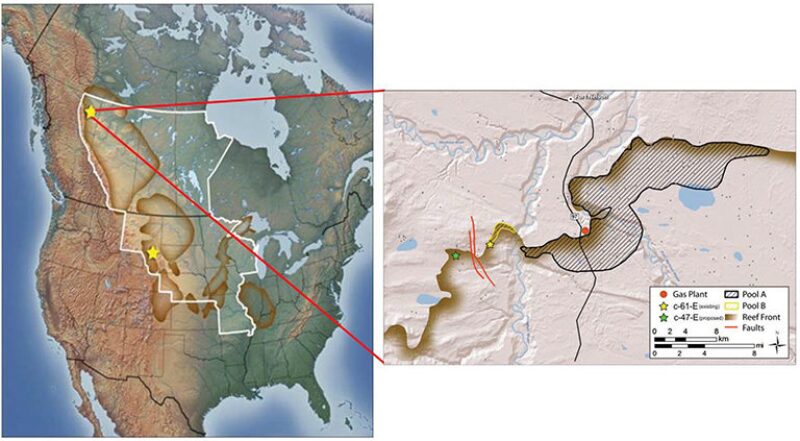

The Plains CO2 Reduction (PCOR) partnership, led by the Energy & Environmental Research Center, is one of seven regional partnerships established under the RCSP program. The PCOR partnership region includes all or part of nine US states and four Canadian provinces (Fig. 1 above) and is made up of many private- and public-sector groups working to identify the most-suitable CO2-storage strategies and technologies, aid regulatory development, educate the general public, and investigate appropriate infrastructure for CCUS commercialization within its region. The Phase-III program includes two commercial-scale projects—the Fort Nelson carbon-capture and -storage (CCS) feasibility project and the Bell Creek CO2-EOR/CO2-storage project.

Fort Nelson. The PCOR partnership and Spectra Energy Transmission are investigating CCUS to mitigate CO2 emissions produced by the Fort Nelson Gas Plant (FNGP) as a waste stream from natural-gas processing. FNGP is near the town of Fort Nelson in northeastern British Columbia, Canada (Fig. 2). The gas stream will include up to 5% hydrogen sulfide (H2S) and a small amount of methane (a sour-CO2 stream). The goal is to capture the stream of sour CO2 that is separated by the current gas-processing operations and store it long term in a deep saline formation. Currently, this sour CO2 is processed in an existing sulfur plant to recover elemental sulfur, and the residual CO2 and sulfur dioxide (SO2) are passed through an incinerator before venting to the atmosphere.

This demonstration project provides an opportunity to develop a set of cost-effective risk-based monitoring, verification, and accounting (MVA) protocols for large-scale (>1×106 t/a) storage of sour CO2 in a deep saline formation. The likely injection target will be a carbonate formation in the Devonian Presqu’ile reef complex, with the 500-m-thick shale of the overlying Muskwa and Fort Simpson formations serving as a seal. The effectiveness of MVA activities will depend partly on developing a thorough geological-characterization, modeling, and risk-assessment effort. The results of these activities will provide insight regarding the behavior of dense-phase sour CO2 in a deep brine-saturated carbonate-reservoir environment; the effect of dense-phase sour CO2 on the integrity of sink and seal rocks; the effects of large-scale sour-CO2 injection and storage on wellbore integrity; the effectiveness of selected MVA techniques; and the use of an approach that combines iterative geological characterization, modeling, risk assessment, simulation, and MVA planning to inject and store large volumes of sour CO2 safely and cost effectively.

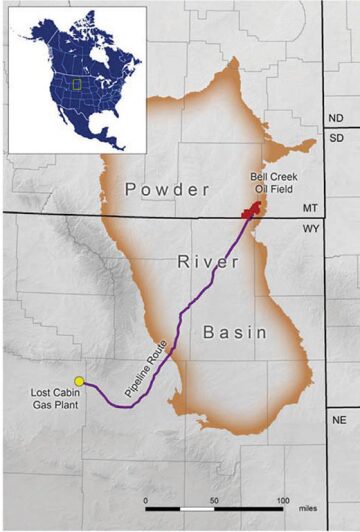

Bell Creek. The PCOR partnership is working with Denbury Resources to determine the effect of large-scale injection of CO2 into a deep clastic reservoir for simultaneous CO2 EOR and CO2 storage at the Bell Creek oil field. A technical team will determine baseline characteristics, perform risk assessment of the injection site and surrounding areas, and establish long-term monitoring protocols for injecting CO2.

The CO2 source will be the ConocoPhillips Lost Cabin gas-processing plant in Fremont County, Wyoming, which currently generates approximately 50 MMcf/D of CO2 (Fig. 3). The CO2 will be transported to the site and injected into an oil-bearing sandstone reservoir in the Lower Cretaceous Muddy (Newcastle) formation at a depth of approximately 1372 m. An estimated 1.1 million tons of CO2 will be injected annually, much of which will be stored permanently.

Similar to the Fort Nelson CCS project, the Bell Creek demonstration project will provide an opportunity to develop an MVA plan for a large-scale CCUS project. In this case, the project will be combined with a CO2-EOR project. The baseline geological characterization conducted over the course of the project will provide data to support design and implementation of an injection/production scheme for large-scale CO2 EOR and storage at the Bell Creek oil field.

Applicability

These projects focus on reducing the CO2 emissions from large point sources, in these cases natural-gas-processing facilities. The benefits of CCUS applied to the Fort Nelson project include:

- The ability to store the CO2 generated at the processing plant reduces the operator’s overall emissions to the atmosphere.

- The geological storage of the produced CO2 and H2S will reduce or eliminate the need for the current sulfur-processing plant, effectively eliminating the need for surface storage of elemental sulfur from this plant and eliminating the flaring of SO2.

- The physical footprint required for gas-processing activities at the Fort Nelson site would be reduced.

For the Bell Creek project, the benefits are twofold:

- The overall CO2 emitted from the Lost Cabin processing facility will be reduced.

- Oil production from the Bell Creek field will be increased.

The Fort Nelson and Bell Creek projects have detailed geocellular modeling and simulation programs. The knowledge gained from these activities has direct application to the oil and gas industry:

- Increased knowledge of geocellular modeling helps characterize hydrocarbon reservoirs and the subsurface in general.

- Increased understanding of how injection and production affect stress regimes within the reservoir and the overlying and underlying formations will provide a better understanding of the potential for induced fracturing and faulting and for induced seismic activity.

- Knowledge of the processes by which fluids migrate and become trapped within the reservoir rock will be gained.

- The understanding of sweep efficiency and CO2 retention for CO2-EOR applications will be increased.

- The understanding of factors that influence the CO2-storage capacity of hydrocarbon reservoirs and saline formations will be increased.

A major component of these demonstration projects is developing a site-specific MVA program. The goal of MVA is to provide critical data that can be used to verify site security; evaluate reservoir behavior during the injection program; determine interactions between oil, water, and CO2 within the reservoir; determine the fate of injected CO2; and investigate mechanisms that affect CO2-storage efficiency within the EOR process. If the MVA program identifies a significant variance from anticipated performance, a targeted characterization effort then could be deployed to evaluate the effect and source of the event.

Conclusions

The overarching philosophy for these demonstration projects involves an integrated approach of site-specific characterization, modeling, simulation, risk management, and MVA. Risk management, modeling, predictive simulation, and MVA are interrelated processes in which the results of one become the input of the others. For example, as knowledge is gained from site characterization, it reduces uncertainty in geological reservoir properties. This reduced uncertainty can propagate through modeling, risk assessment, and MVA efforts. As an EOR or storage project moves forward, it will advance through several phases (e.g., feasibility, design, injection, closure, and post-closure) and this integrated approach creates a dynamic iterative process that can be used to monitor and review changes as the project progresses. This integrated approach provides insight into the ability to predict and assess subsurface technical risks associated with EOR and CO2 storage. The development and validation of this methodology through these demonstration projects can enable benefits from this integrated approach by applying it to future projects.

This article, written by Senior Technology Editor Dennis Denney, contains highlights of paper IPTC 17089, “The Plains CO2-Reduction Partnership: CO2-Sequestration Demonstration Projects Adding Value to the Oil and Gas Industry,” by Charles D. Gorecki, Edward N. Steadman, John A. Harju, James A. Sorensen, John A. Hamling, SPE, Lisa S. Botnen, Scott C. Ayash, and Katherine K. Anagnost, Energy & Environmental Research Center, prepared for the 2013 International Petroleum Technology Conference, Beijing, 26–28 March. The paper has not been peer reviewed. Copyright 2013 International Petroleum Technology Conference. Reproduced by permission.