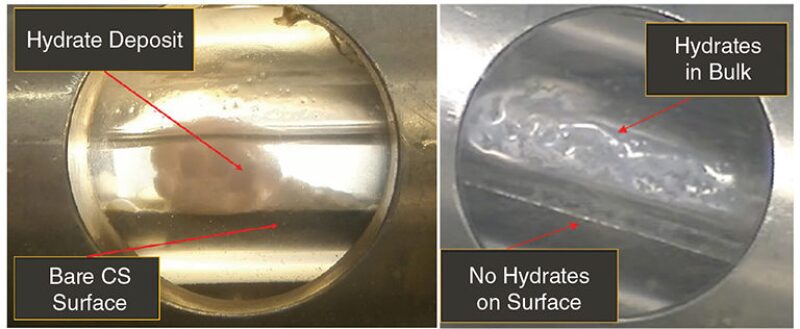

When certain thermodynamic conditions exist in oil- and gas-production flowlines, gas-hydrate plugs can form and greatly restrict flow. One potential strategy for hydrate management involves allowing hydrates to form but mitigating their ability to deposit on the flowline walls by deploying a low-adhesion, protective surface coating on the inside wall of the flowline. In this study, two coatings were produced and evaluated to determine their effect on hydrate adhesion onto carbon-steel surfaces.

Introduction

In order to test the adhesion of hydrates to the two low-surface-energy coatings, micromechanical-force (MMF) apparatuses were used at low and high pressures. MMF apparatuses have been used historically to investigate both hydrate/hydrate interparticle forces and hydrate/surface interactions.