Remotely operated vehicles (ROVs) are used by the offshore oil and gas industry to monitor the integrity of subsea infrastructure and, in doing so, collect terabytes of video and in-situ physical data from inaccessible regions and poorly understood marine environments. The complete paper describes the potential global scientific value of video and other data collected by ROVs.

ROVs and the Offshore Oil and Gas Industry

Nearly one-third of global production of oil and gas is sourced offshore. Tens of thousands of offshore wells have been drilled, and more than 900 large-scale offshore oil and gas platforms have been installed. The offshore industry relies on underwater observation, control, and intervention, tasks performed increasingly by ROVs; over 700 were in operation globally at the time the paper was written. The advancement of ROV technology for the industry was prompted in the 1970s by developments extending into water depths beyond the capabilities of divers, and by the desire to reduce reliance on diving operations.

Modern ROVs fall into two main classes: work class and observation class. A work-class ROV is car-sized, usually cuboidal, with a buoyant upper part containing power equipment, thrusters, manipulators, and cameras. An umbilical connection to the surface vessel provides electrical and fiber-optic connections that allow control and data transfer. Observation-class ROVs are smaller—sometimes briefcase-sized—with limited power and manipulation capabilities, and are used primarily for inspection purposes. For observation missions that can be conducted without real-time intervention, autonomous underwater vehicles (AUVs) are increasingly popular. These are generally torpedo-shaped, with higher hydrodynamic stability than ROVs, and can offer a similar image-gathering platform.

Oil and gas projects and other ocean-based industries such as offshore wind use ROVs at multiple stages in a project’s life. Surveys of the region before installation or construction are conducted using ROVs or AUVs to identify the bathymetry and substrate conditions for hazard assessments and to provide parameters for engineering design. Drilling activities commonly involve ROV monitoring at the seabed level, and, when the production facilities are installed, ROVs are used to perform observation of all subsea activities. During operation of a project, ROVs are used for inspection and intervention. The manipulators operate valves and interchange components, and, if required, can undertake cutting. Inspections include visual surveys as well as checking of anode electropotentials and clearance of marine fouling. Inspections commonly are undertaken annually but can be more or less frequent depending on risk level and maintenance requirements. In total, the ocean around a typical oil and gas development may be visited dozens of times by ROVs during the project’s life.

Industry ROVs are essential for understanding the environmental implications of decommissioning activities. More than 7,500 offshore oil and gas structures will approach obsolescence globally over the next 2 decades, and most will require complete removal under current regulations. However, there is little understanding of the environmental effects of complete removal of subsurface structures on offshore ecosystems, particularly the cumulative effects across and beyond once-active regions. Alternatives to complete removal, in which some of the structure could remain in the marine environment, may also provide better environmental outcomes in particular circumstances. There is an imperative to pursue a deeper understanding of this potential, because alternative decommissioning approaches, such as leaving structures in situ, could be favorable environmentally and economically, thus unlocking societal benefits relative to today’s practices.

The ecological value of existing ROV data represents an immense and underused resource with worldwide coverage. The industry can use these data to improve knowledge of marine biodiversity on and around offshore infrastructures and their environmental effect on marine ecosystems, both of which are important in the consideration and selection of decommissioning strategies. Predicting the environmental consequences of removing or retaining subsea structures after decommissioning relies on an understanding of the ecological communities that have developed in association with these structures during their operational lives. Making industrial ROV data available for scientific research and collating the data in the future using modified protocols would provide a positive contribution to both science and industry, allowing the environmental effect of subsea infrastructure to be quantified. The use of this data will also allow industry to contribute to a broader scientific understanding of our oceans, given the location of ROVs in areas that can rarely be accessed by independent researchers.

Understanding the Role of Marine Life on Pipelines

Modern pipeline systems can be designed to be dynamically stable—meaning that a certain level of lateral movement is permitted during storm loading—and to buckle laterally back and forth across the seabed to accommodate thermal expansion.

As part of a PhD research project based at the University of Western Australia, a pipeline on Australia’s North West Shelf was subjected to a longitudinal study of engineering conditions, using data gathered during the pipeline life, including local metocean conditions, operating conditions (internal temperature and pressure), and information from ROV inspection surveys. These data included both acoustic surveys and video footage. If made available for research, they have immense potential to quantify marine ecology and assist good stewardship of the environment by industry. Most ROV operations are conducted in a way that fulfills immediate industry requirements but can confound scientific interpretation of the data. For example, there is variation in video resolution, ROV speed, distance above substrate, and time (both seasonal and time of day); these variations can limit the quantitative conclusions that can be drawn about marine ecology. The authors examined potentially cost-effective enhancements to standard ROV hardware and operational procedures that could increase the value of future industrial ROV operational data without disrupting the primary focus of these operations.

The particular pipeline discussed in the paper had been designed both to buckle laterally back and forth with changing temperature and to be dynamically stable during storms. The seabed was susceptible to erosion and scour in the region, particularly close to the pipeline where the seabed shear stress caused by ocean currents is amplified as the flow passes over the pipe.

The study determined that the burial condition of the pipeline changed during operating life, with an increase in the average burial of the pipe as the result of a combination of processes including scour, erosion, span development, sinkage of the pipeline at the end of spans, and sedimentation alongside the pipeline. An initial study quantified the changing embedment with a focus on the length-averaged behavior, but unanswered questions remained at certain locations where deep scour pits were apparent, with the pipe spanning over them.

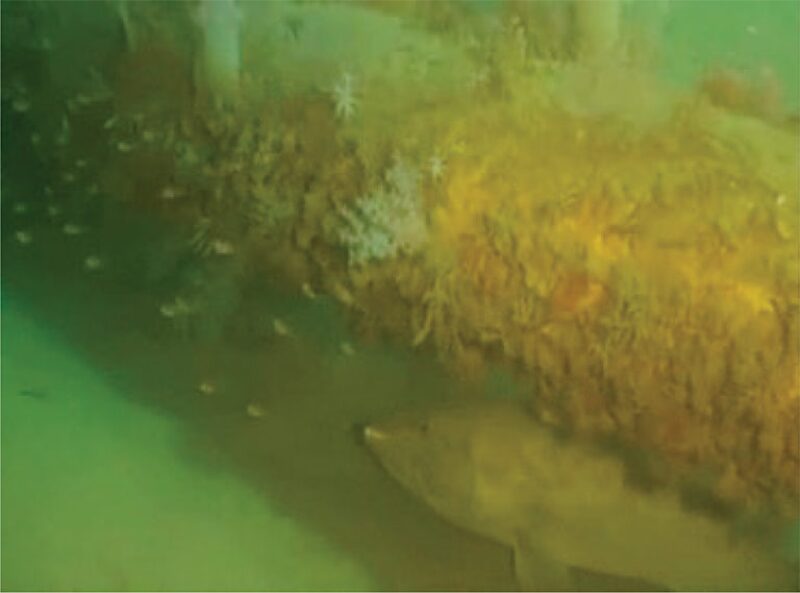

At these span locations, the shape of the holes beneath the pipeline was not consistent with the hydrodynamic processes that create scour holes from piping and tunnel flow. The scour holes had steep-sided walls and were sometimes asymmetric or had deeper secondary holes at the base. In some cases, the total depth relative to the pipeline diameter exceeded what was possible as a result of hydrodynamic action alone. When the engineers analyzed the ROV video with a marine ecologist, they recognized that fish were likely playing an important role in increasing holes beneath the pipeline—an influence that had been overlooked in previously published physical and numerical modeling work disseminated in the engineering literature (Fig. 1). These holes interact with the sediment transport processes driven by the tide and internal waves, and are correlated with areas of increased marine life adjacent to the shelf break and some shallow reefs.

These observations did not create concern regarding pipeline integrity, but they altered the basis on which the pipeline burial condition should be extrapolated into the future. They also created awareness of an additional mechanism that can trigger pipeline burial processes (which have a net positive effect on pipeline stability) that has now entered local engineering wisdom. Meanwhile, concurrent research also focused on the North West Shelf provided similar evidence of fish contributing to changes in pipeline burial. It was suggested that grouper species were likely responsible for creating pock marks in the vicinity of pipelines and distinctive cones of sediment in which excavated debris is deposited.

This article, written by JPT Technology Editor Judy Feder, contains highlights of paper OTC 28312, “Understanding the Global Scientific Value of Industry ROV Data To Quantify Marine Ecology and Guide Offshore Decommissioning Strategies,” by D.L. McLean, University of Western Australia; P. Macreadie, Deakin University; D.J. White, University of Southampton and University of Western Australia; P.G. Thomson, University of Western Australia; A. Fowler, New South Wales Department of Primary Industries; A.R. Gates, National Oceanography Centre, UK; M. Benfield, Louisiana State University; T. Horton, National Oceanography Centre; D. Skropeta, University of Wollongong; T. Bond, University of Western Australia; D.J. Booth, University of Technology, Australia; E. Techera, C. Pattiaratchi, and S.P. Collin, University of Western Australia; D.O.B. Jones, National Oceanography Centre; L. Smith, Woodside Energy; and J.C. Partridge, University of Western Australia, prepared for the 2018 Offshore Technology Conference Asia, 20–23 March, Kuala Lumpur. The paper has not been peer reviewed. Copyright 2018 Offshore Technology Conference. Reproduced by permission.