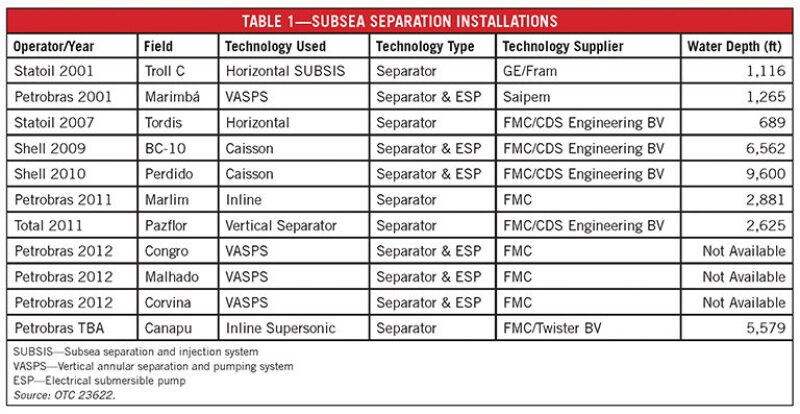

The adoption of subsea processing, including separation, pumping, and compression, is growing (Table 1). High water cuts and limited-capacity topside facilities are among the drivers.

The OTC 2012 Spotlight on Technology awards highlighted two FMC Technologies systems in the Pazflor and Marlim fields. The world’s first installation of subsea separation and boosting in a new subsea field that will produce two grades of oil (light and heavy) was installed in Pazflor field, offshore Angola. The equipment installed in the Marlim field, offshore Brazil, is the industry’s first use of oil and water separation technologies in deep water, and the first subsea system to separate heavy oil and water. It is also the first to reinject separated water back into a subsea reservoir to boost production.

Expanding regulations and changing requirements globally will promote the development and advancement of monitoring and measurement technologies for subsea processing systems. In April, Timothy Daigle, senior project engineer with the subsea engineering group of Fluor Offshore Solutions, discussed the need for advanced capabilities at a Society of Petroleum Engineers Gulf Coast Section projects, facilities, and construction study group luncheon, “Subsea Produced Water Treatment Measurement Challenges.”

Daigle noted that the control and monitoring of subsea processes will be critical in demonstrating to regulatory agencies that the processes are working, effective, and compliant with regulations. From a review of state of the art technologies relevant to seabed produced water treatment and discharge, Daigle presented the following main findings:

- There are a limited number of subsea projects that separate oil and water, and there is no subsea water treatment for discharge.

- Subsea separation technologies have focused on two-phase gas-liquid separations. Installations with oil/water separation were intended for injection of produced water into wells, which allows higher oil-in-water content than permitted by regulatory discharge limits.

- Current subsea oil/water separation systems are capable of achieving oil-in-water concentrations of several hundred ppm, which is approximately 10 times the discharge limit.

Measurement and Monitoring Challenges

Daigle said that multiphase flowmeters are currently the most commonly used measurement technology in subsea processing installations. Typical measurement principles, not yet used in subsea applications, include:

- Direct methods-measurement of weight

- Indirect methods-colorimetric, infrared, ultraviolet fluorescence, and particle counting

Emerging and new technologies for measurement and monitoring include:

- Inductance-used to detect changes in conductivity; configured as a vertical stack of sensor elements, each measuring the conductivity in its vicinity

- Microwave-used to measure fluid levels and to detect water cut (e.g., Agar Corporation’s water cut meter)

- Near-infrared absorption-Weatherford’s Red Eye water cut meter

- Ultrasonic-NIMTech’s SonicGauge (not yet commercialized) non-invasively sees through a pipeline or container to track the chemical fingerprint (solid, liquid, or gas) of substances and processes changes in their composition in real time

- Photometry-Optek’s TF16 scattered light, inline turbidity sensor

Reliable and accurate subsea water quality measurement devices will need to work reliably to water depths of more than 9,000 ft with the temperature and pressure of process fluids far higher than that experienced on the surface. Testing and qualification will play a vital role in the technology development and deployment.

For Further Reading

OTC 23622 Treating and Releasing Produced Water at the Ultra Deepwater Seabed by Timothy P. Daigle, Savanna N. Hantz, Brian Phillips, Fluor Offshore Solutions, et al.