Introduction

Well abandonment is nothing new to the oil and gas industry—it is an activity that has been associated with well construction since the very beginning of the search for hydrocarbons. One thing that is changing, though, is the sheer volume of wells and fields that are currently shut-in, suspended, or reaching the end of their economic life. Worldwide, governments and legislative authorities are encouraging the oil and gas industry to seal and permanently take offline unproductive wells to prevent them from impacting the environment.

In certain mature basins the decommissioning of aging infrastructure is creating such a significant volume of wells to be abandoned that these are now being treated as standalone projects rather than the responsibility of existing asset teams and contract models. For the service companies this large potential business opens up the possibility of the development of tools that can be used to limit the economic impact to operators and also enable fulfillment of the abandonment obligation.

Managing the Cost of Abandonment

The decision to plug and abandon (P&A) a well or field is invariably based on economics. Once production delivers less than the operating expenses, it is time to consider abandonment. In fact, in some cases the decision is made with the knowledge that considerable reserves remain, but the cost to extract these resources is more than the projected income.

The cost to P&A a well can vary by many millions of dollars depending on location, and whether the well is offshore or onshore. In the UK, abandonment from a fixed platform will be around USD 2 million, whereas abandonment from a semisubmersible or dynamic positioning drilling unit can be USD 10 million.

In an effort to reduce the cost of abandonment operations, operators and regulators strive to improve how P&As are performed and the service companies are continually developing tools and techniques to increase efficiency without compromising safety.

Minimizing costs, without sacrificing well integrity, is critical to operators, who make a significant investment with no financial return in the case of P&A operations.

Legislation and Design

With regard to global offshore markets, two areas that today have an established and growing portfolio of continuous well abandonment activities are the Gulf of Mexico (GOM) and the North Sea. Both are long-established producing areas that contain mature fields and aging infrastructure. As a result, both the North Sea (regulated in the UK by the government’s Health and Safety Executive and in Norway by NORSOK standards implemented by independent organization, Standards Norway, which is a member of CEN and ISO) and the GOM (regulated in the US by the federal government’s Bureau of Safety and Environmental Enforcement [BSEE]) have well-defined legislation and practices regarding how abandonment operations should be conducted.

For example, the BSEE introduced “Idle Iron” regulations and guidelines for nonproducing wells in the GOM in a Notice to Lessees (known as an NTL), effective October 2010, which aims to provide oil and gas companies with some clarity about the required standards and outcomes expected as part of an abandonment philosophy.

The UK offshore oil and gas advocacy organization, Oil & Gas UK, offers (for a price) Guidelines for the Suspension and Abandonment of Wells, in which it states the following: “All Distinct Permeable Zones penetrated by the well should be isolated, both from each other and from the surface or seabed by a minimum of one Permanent Barrier. Two Permanent Barriers from surface or seabed are required if a Permeable Zone is hydrocarbon bearing or overpressured and water bearing.”

In addition, the same guidelines state the following for subsea wells:

- “Redundant subsea equipment must not present a hazard to other users of the sea.”

- “It is seen as good practice to retrieve all casing strings to minimum of 10 ft below seabed.”

- “All subsea equipment and debris should be retrieved where practical.”

The basics of a permanent well abandonment (PWA) operation will vary little whether the well is on land or offshore. You begin by removing the completion or production string, then set the necessary plugs and cement barriers at specified depths across the producing and water-bearing zones to act as permanent barriers. It sounds so simple, but it is crucial to remember that the key to a successful operation will be a solid plan. Unfortunately, many times this is hampered by lack of data and/or outdated files. The wellhead and subsea hardware (if applicable) are removed last.

When operators abandon a well they are obligated to leave it in a condition that protects both the downhole and surface environment in perpetuity.

In all parts of the world, regulatory bodies have, to varying degrees, defined procedures and responsibilities for a PWA.

Despite disparities around the world, the intent of all abandonment operations is to achieve the following:

- Isolate and protect all freshwater zones.

- Isolate all potential future commercial zones.

- Prevent in perpetuity leaks from or into the well.

- Cut pipe to an agreed level below seabed and remove all surface equipment.

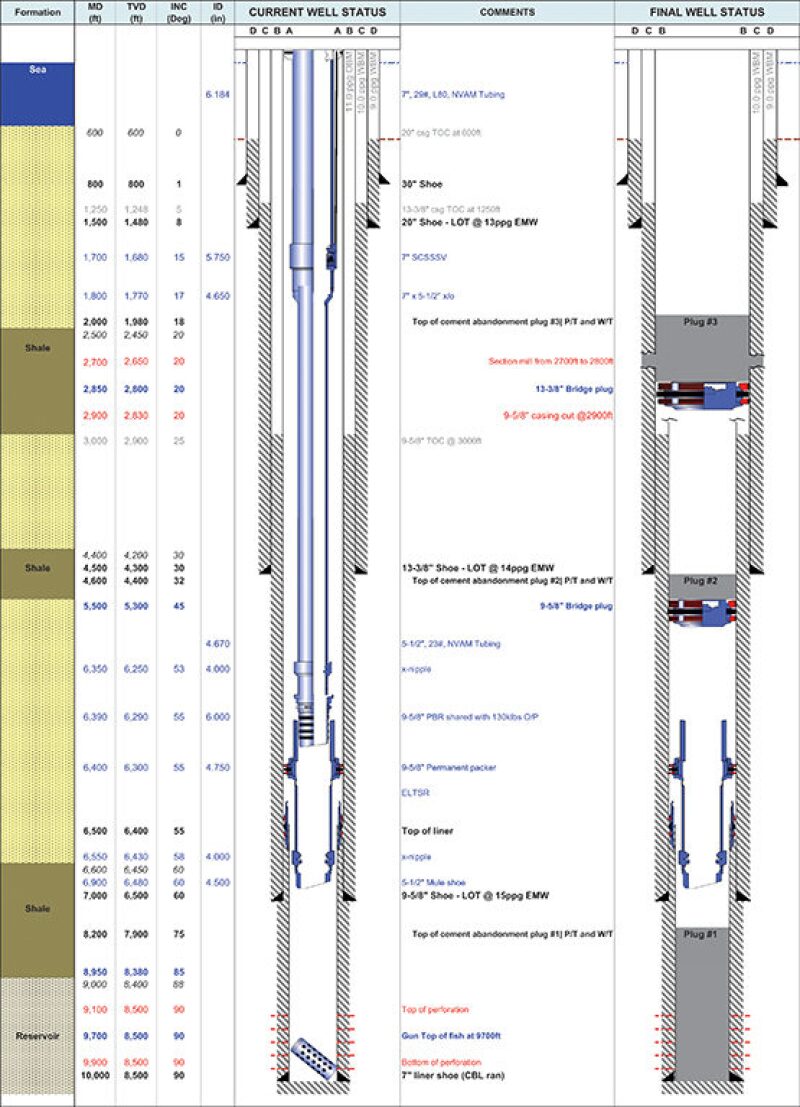

Fig. 1 illustrates an example of a well before and after the abandonment process has been completed. In this case, the well abandonment procedure could be considered quite complex due to the need to remove tubing and 95/8-in. casing, and section-milling 133/8‑in. casing in order to isolate all the required intervals. Not all wells will require this level of deconstruction, but the principal objectives will be similar.

In general, a large number of well abandonment operations could be carried out in a rigless manner. This will invariably save cost overall but can increase the operational time required. Rigless abandonments include the use of highly mobile equipment spreads, such as pumping skids and jacking units. However, the complexity of the initial well design, coupled with possible well issues such as multiple annular pressure issues and lack of wellbore access, may dictate that a rig-based approach is required.

Technology Opportunities

Within the scope of well abandonment, many techniques used today can be considered evolutions of those employed for many years. Cement is still used as the primary barrier. Logs generated by cement-bond logging tools are still used to evaluate cement quality. Milling and fishing tools remain similar in nature.

With the continued increase in the volume of wells to be abandoned, it is reasonable to suggest that the pace of technology development and deployment around abandonment operations should and indeed must accelerate in order to increase the efficiency and effectiveness of abandoning wells. Opportunities exist for the development of alternatives to milling, for more advanced measurements to see through multiple annuli before the removal of tubing and casing, and for alternative isolation materials and long-term monitoring solutions to provide verified evidence of lasting isolation.

Summary

The industry globally is facing its busiest period ever in relation to abandonment work. With drilling activity adding thousands of wells per year, the volume of this type of work will only continue to grow. The industry needs to address PWA requirements by assigning appropriate resources in both operators and service companies to ensure that a skilled and competent workforce along with fit-for-purpose technology solutions are in place to meet the challenge. The perception that well abandonments involve just a simple reverse-engineering workflow and require only the most basic of tools is far from reality. Well abandonment represents a true challenge that will be here for decades.

Kenny Campbell has over 30 years of experience in the field of well abandonment and workover. Currently he is the well abandonment & decommissioning technology manager for the Schlumberger Integrated Project Management Segment. Before this Campbell served in several technical and managerial roles in the industry including region product line manager with Weatherford, Middle East manager with Norse Cutting and Abandonment, and owner of Deepwater Abandonment Services.

Rod Smith is currently manager of the Schlumberger Well Abandonment Business Unit in the North Sea, part of the company's Integrated Project Management Segment. He has been with Schlumberger for the past 15 years and has served in several field, sales, personnel, and managerial roles. Smith took on his current role in March 2012, before which he was a group account manager for several North Sea-based customers.