Oil companies exist to make money. Many companies too often focus solely on maximizing current production when they should really be focusing on maximizing profitability. A holistic, total asset modeling process is needed to reorient the focus of digital oilfield systems to make the net present value (NPV) of every project the centerpiece of all decisions.

Digital oil field providers have spent the past decade enabling a growing variety of specific workflows to automate isolated engineering tasks. These efforts have significantly reduced nonproductive time and costs. Nevertheless, transformational productivity increases will be required for operators to thrive in a prolonged, low oil price environment. For this reason, digital oil fields must become less about workflow orchestration and more about financial optimization.

A variety of metrics are used in the industry to measure financial performance or to make capital budgeting decisions. In addition to NPV, the metrics may include internal rate of return (IRR), real options analysis, or payback period. Among these, payback fails to account for the time value of money, IRR does not return a unique solution in cases where positive and negative cash flows alternate over time, and real options analysis can be shown to be equivalent to the NPV method if risk is properly accounted for.*

Less formalistic measurements may also come into play, particularly where projects involve national oil companies for whom politics, short-term cash flow pressures, and regulatory frameworks can exert large influences over the selection of a project.

Without a significant loss of generality, we claim that if a business activity is not expected to increase NPV, then it should not be undertaken. Under this assumption, well-intentioned, but NPV-reducing, programs of activity that are proposed to improve a technical metric should be reconsidered. For example, reservoir engineers will always try to improve their recovery factors, but economic limits will dictate the scenarios in which oil should be left in the reservoir.

In a company in which groups or teams are accustomed to operating in silos, the financial effect of decisions can be opaque, particularly at the level of decision making required to manage globally dispersed, cross-functional teams. To improve transparency, it is insufficient for only managers to have visibility into the financial effect of technical decisions. Technical personnel also need to know that their work is improving the bottom line. As they gain greater financial awareness, employees will begin making more improvements to their technical projects in ways that optimize profitability.

Modern digital oilfield platforms have grown in sophistication to the point of offering software-enabled processes that can aggregate the results of every technical and economic analysis with real-time operational data, and generate continuously updated calculations of project NPV. Moreover, the NPV of a project can be presented in the context of a dynamically updated database of comparable projects that are drawn from every region of the world. Using these processes, operators have constant awareness of how the profitability of an asset is faring against industry benchmarks. Individual personnel can also immediately see the financial consequences of engineering model updates on corporate-level NPV estimates.

This approach is based on a fundamental software mapping that transforms engineering calculations into financial results. Advanced data analytics can now combine decades of industry data. These data include the costs of everything, including sheet steel and offshore labor, needed to build an oil field; commodity price forecasts; rich archives of geological properties from every region of the world; and a library of actual, historical financial asset performance. All these data can be used to accurately predict the NPV of proposed new projects.

The resulting predictive capabilities may span the complete range of rigs, platform types, export methods, and production strategies available to operators, which reduce the need for manual iteration.

Composite Models

A key to the success of these new modeling approaches has been abstracting the complexity of real asset performance into a manageable number of key variables that can be measured and updated. These abstractions take the form of composite models, or templates, of producing assets that are created at the beginning of the appraisal phase. A composite model persists throughout the life of the asset and is continuously updated as operational data are gathered. The key variables that most affect NPV are recoverable reserves, oil price, initial well-production rates, well drainage areas, and pay zone depths.

Values for these key variables in the composite model are generated from associated engineering and economic models, the same ones that will be used during the producing phase of the asset’s life cycle, rather than from coarse approximations or purely empirical correlations. Using the same models throughout the life of the asset ensures continuous improvement of model accuracy, better auditability of changes, and earlier reduction of uncertainty.

Composite models are sophisticated analytical tools that are prebuilt to represent particular asset development strategies. They include appropriate default values to provide the necessary level of detail, particularly at the beginning of a project and for variables to which the NPV is less sensitive. Consequently, composite models enable operators to quickly match a potential prospect to a set of integrated economic, geological, and engineering submodels that reflect comparable historical project data. The more the supporting submodels are improved, the better the composite model will be able to serve as a template for similar future projects.

Composite models accelerate the work of initial development and systematically build in the best practices of the operator at each subsequent project phase.

In addition to reducing field development lead times, composite models help to enforce corporate best practices for particular asset types. They also serve as a container for lessons learned during a project. The use of real models, with realistic input values available at the outset of asset appraisal, enables their modification over the asset’s life cycle; these modifications can be saved in an audit trail. The ability to objectively audit past decisions helps managers diagnose cost overruns, assist with regulatory compliance, and train new personnel quickly.

Composite models have created new ways for operators to address shortages of qualified new hires, accompanied by the retirement of experts who often fail to adequately train replacements, and the stewardship of complex business processes that represent valuable intellectual property.

NPV and Technical Decisions

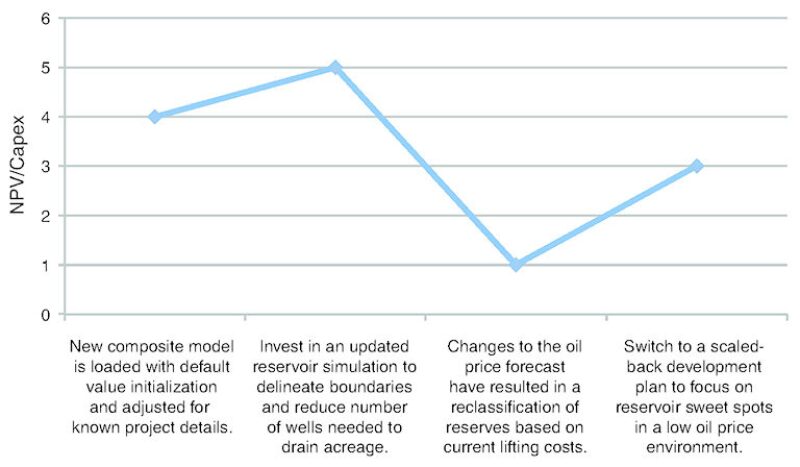

The NPV effects typical decisions that could be made to develop an asset and how the use of composite models can drive profitable decision making. An economic analysis is a core component of composite modeling. Because economic submodels are run each time that an engineering submodel is changed or added, the NPV effect of technical decisions is immediately visible.

Composite models can be used to track the ratio of projected NPV to capital expense (Capex) for projects based on interactions among the participating submodels that are being updated with real-time market and engineering data. Corrective actions can be taken earlier because the business justifications for budget requests are more apparent and easier to communicate to senior executives. Employees from all functional areas become incentivized to track changes in asset profitability and receive instant feedback on how decisions are affecting profitability. Overruns or suboptimal strategies can be more easily recognized and reversed before they become sunk costs.

The composite modeling process can alternatively be understood by the following representative sequence of steps:

- Identify the set of key variables to which project NPV is expected to be most sensitive.

- Estimate the initial values of the key variables and run the central simulation controller module, which generates an engineering (e.g., pre-front-end engineering design) concept for the project that maximizes NPV within known constraints.

- Validate the default input generated by the central simulation controller module for each participating submodel (such as reservoir, well, surface facility, and reserves) and refine if needed.

- As the development and production of the asset progresses, continually update the submodels with more accurate values drawn from operational data.

- Update the engineering concept based on new data as they become available in the simulation controller module. Users may override changes to enforce corporate best practices or other constraints.

- Transfer ownership of the supporting submodels to appropriate technical specialists, who will maintain them over the economic life of the project.

- Continuously relate the effects of technical submodel changes to changes in project NPV, and make these changes available to project stakeholders at all levels. These changes can be traced (audited) to corresponding technical decisions.

Different types of workers will apply composite modeling differently. Likewise, companies will apply composite modeling differently for the various projects in their portfolios, based on their respective phases in the oil and gas asset life cycle. Because submodels spanning every discipline are represented in composite models, the users of composite modeling may include all the domains and levels of management involved in oil and gas project development, including the following:

- Executives (asset portfolio management)

- Business development managers (property acquisition)

- Asset managers (field development planning and evaluation)

- Financial analysts

- Geoscientists

- Reservoir engineers

- Drilling engineers

- Subsea engineers (umbilicals, risers, and flowlines)

- Production engineers (wells and surface facilities)

- Operations and maintenance engineers

Some of the diverse activities that can be accelerated and made more profitable through the application of composite modeling are the following:

- Acquisition and divestiture of assets

- Performing high-level capital budgeting exercises for oil and gas asset portfolios

- Planning and executing new projects

- Providing oilfield services to third-party development projects

- Managing exploratory drilling programs

- Managing workovers and debottlenecking projects

Composite modeling enables complex, multidisciplinary decisions to be made more quickly by eliminating information gaps, streamlining review and approval, and encouraging all team members to consider ways to improve the financial effect of their assigned tasks on the project at a corporate level.

The benefits of composite modeling can accrue quickly, across teams and functions, and at any point during the life of a project or asset. Composite modeling enhances projects as diverse as the consideration of a bid to purchase an offshore block; deciding whether to build a fixed offshore platform or use a floating, production, storage, and offloading vessel; or making corporate-level decisions about how to manage the balance sheet. The success measurement of that enhancement is in clearly understandable terms: the change in project NPV.

Composite modeling requires a change in mind-set across the organization. The financial side of the business must learn to see more deeply into ongoing operational programs and look for untapped potential. Operational personnel need to develop a heightened awareness of corporate financial metrics, how those metrics are changing, and how their actions can influence those metrics.

Composite modeling transcends conventional notions of collaboration; it connects everyone, regardless of rank, function, or location, through the common goal of increasing the NPV of every project. Composite modeling results in a transparent, continuous focus on profitability, a shared language that breaks down barriers to progress by democratizing the ability to make a positive effect in the workplace.

*Arnold, T. and Shockley, R.L. (2002), “Real Options Analysis and the Assumptions of the NPV Rule,” 6th Annual Real Options Conference, Paphos, Cyprus, July 6, http://www.realoptions.org/abstracts_2002.html.