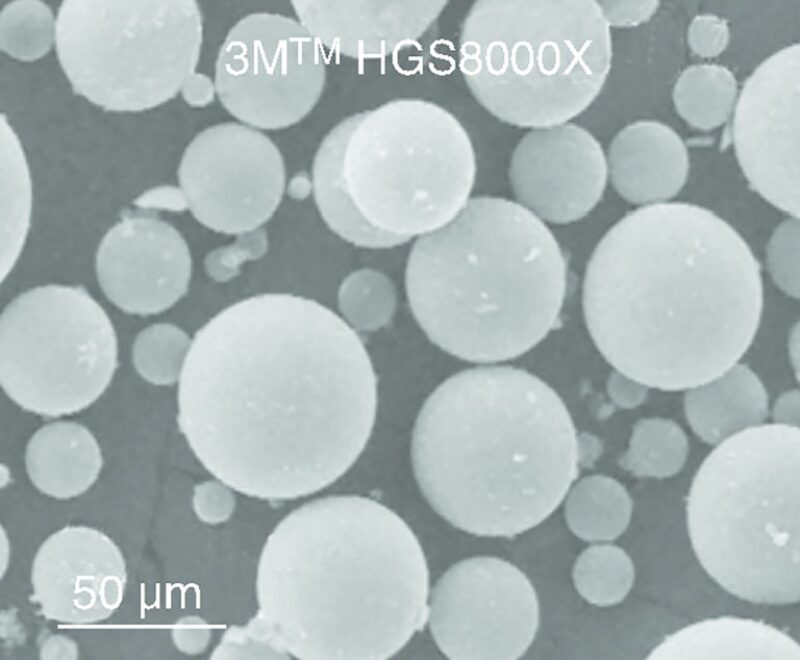

In an effort to optimize drilling operations and economics, an operator examined the effect of adding hollow glass spheres (HGSs) directly to the drilling fluid instead of performing underbalanced drilling. Both nitrogen and HGSs were believed to reduce hydrostatic pressure of the mud column in the hole, resulting in higher drilling rates of penetration (ROPs) and reduced mud losses to the wellbore. This paper provides information on HGSs as an economic alternative to nitrogen to help reduce the hydrostatic pressure of invert-emulsion drilling fluids.

Introduction

This case study focuses on the application of HGSs in two different sections of the drilling operation—a horizontal section and a vertical intermediate section. Data from a base-case horizontal section using an all-oil drilling fluid were compared with data of another well on the same drilling pad using the same fluid with the addition of HGSs.