For thin-oil-rim reservoirs, well placement, type and path, and well-completion methods, should be evaluated with close integration of key reservoir- and production-engineering considerations. This process involves maximizing reservoir-fluid contact and drainage, optimizing well productivity, and optimizing the production profile along the wellbore. Field-implementation cases in Malaysia have demonstrated that this integrated approach to horizontal wells can significantly minimize well count, enhance well performance, and improve ultimate recovery per well in thin-oil-rim reservoirs with varying reservoir complexities and uncertainties.

Introduction

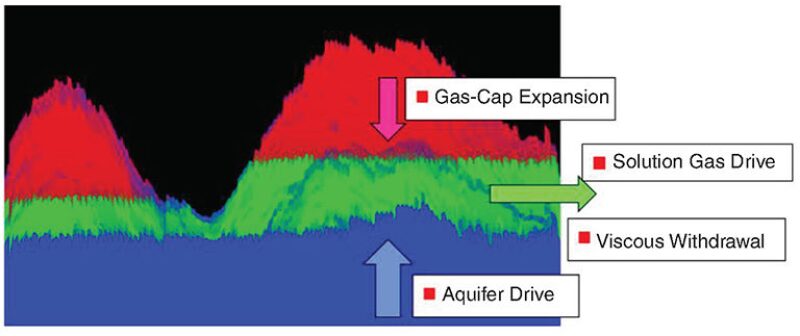

Development of oil-rim reservoirs in Malaysia has improved progressively through a series of reservoir-engineering studies and successful field implementations. Although typical oil-rim reservoirs are characteristically wedged between a gas cap and an underlying aquifer, they can be structurally complicated by faults and flow boundaries, featuring various dips and saddles.