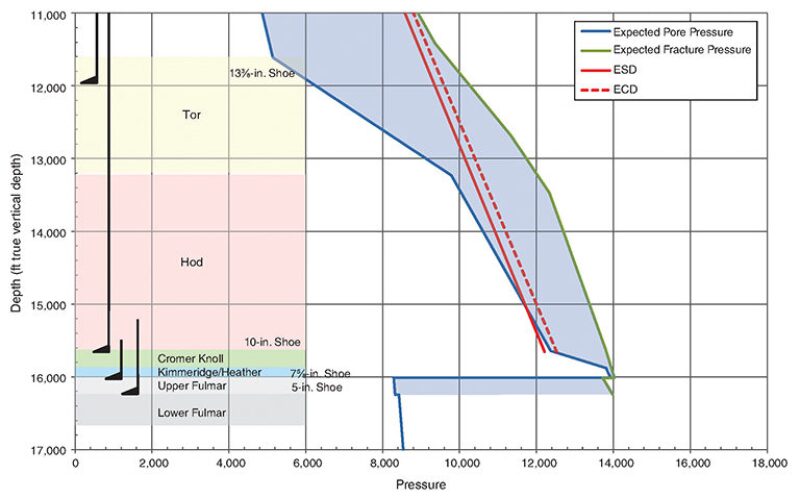

The Shearwater field is a deep, high-pressure/high-temperature (HP/HT) reservoir located in the UK Central Graben of the North Sea. A high level of reservoir depletion (greater than 8,000 psi) has resulted in significant changes to the drilling envelope that has added complexity to the drilling practices required to exploit the remaining reserves successfully. Managed-pressure-drilling (MPD) technology was implemented in conjunction with drill-in liner and wellbore-strengthening technologies to successfully deliver the first well in a redevelopment campaign and prove the techniques required to prolong field life.

Shearwater Overview

Shearwater is an HP/HT gas/condensate field discovered in 1988. Primary production is from the Fulmar, a sandstone reservoir with virgin pressure of 15,400 psi and temperatures greater than 360°F. The field came on stream in 2001. The large field-pressure depletion resulted in compaction at the Fulmar formation level and led to mechanical failure of the production liners because of shear deformation.

A drilling campaign to restore Fulmar production was initiated in 2013. The primary plan was to abandon the existing reservoir sections of the wells and perform shallow sidetracks from the 20-in. casing.