Historically, invert-emulsion drilling fluids (IEFs) require organophilic clays to provide viscosity and suspension characteristics. While effective, these chemicals are prone to stratification in certain conditions, slow chemical-reaction times, high pressure spikes, and high equivalent circulating densities (ECDs). This paper describes the first application of clay-free IEFs in the Norwegian continental shelf (NCS), with an emphasis on an impressively low and consistent ECD contribution. Further, a treatment was developed to allow the IEFs to be used to drill into a section exhibiting temperatures greater than 160°C.

Introduction

IEFs have been used in the NCS for almost 50 years. These systems commonly use organophilic clays and lignites as their primary viscosifiying and filtration-control agents. IEFs containing these compounds have been found to exhibit a higher propensity for fluid stratification than IEFs that use polymers for viscosity and filtration control. Until recently, organophilic clays and lignites have been the primary means to provide viscosity and filtration control in IEFs. While these chemicals are effective, there are several inherent limitations, including high pressures spikes when applying force following a static period and stratification of the fluid. The latter can lead to settlement of weighting agents in a wellbore. In addition, organophilic-clay additives are known to react much slower than polymer-based additives, reducing their effectiveness to maintain fluid properties. This can lead to destabilization of the fluid such that stratification and high filtrate loss can occur, leading to instances of stuck pipe and poor hole cleaning and to well-control concerns. Polymer-based viscosifiers generate suspension characteristics by seemingly unconventional and contradictory means; high gel strengths are generated extremely rapidly but are easily broken. Because of such behavior, they are often referred to as strong yet fragile gels. In addition, at low fluid densities, these systems are less likely to induce losses through decreased solids loading, which can often be attributed to clay and lignite concentration.

Before new chemicals can be introduced into the Norwegian market, stringent environmental requirements must be met. The pre-existing viscosifying polymer used globally in clay-free systems is classified as “black” in Norway because of its inability to biodegrade, meaning it cannot be used. To address this, a polymer-based viscosifying agent has been developed to replace organophilic clay and serve as a much more environmentally acceptable substitute.

Clay-Free-IEF History

Devised for deepwater wells, clay-free IEFs were first developed in 2001 in the Gulf of Mexico. These fluids were designed to operate in both low- and high-temperature regimes. The polymer chemistry provided a significant resistance to cold temperatures; rheologies in clay-free IEFs were significantly lower than those measured in conventional IEFs at low temperatures (e.g., 4°C), an important observation for fluid viscosity in deepwater marine risers. The transition from clay-based chemicals necessitated evolution toward an emulsion-based control of the viscosity. Clay-free IEFs use the emulsion to derive the required rheological profile more so than traditional fluids. An increase in the aqueous phase of between 5 and 10%, in combination with these new technologies, allowed the unique suspension and gelation characteristics to be realized. This technology was soon adopted for global use.

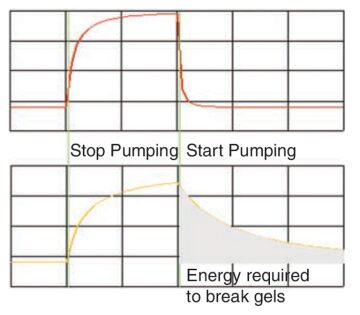

Clay-free IEFs are designed to provide a much stronger gel structure than traditional IEFs. However, upon the application of force, these gels break extremely easily, reducing wellbore stresses and pressure spikes, which are a common cause of losses downhole. Fig. 1 highlights this effect and how it differs in comparison with traditional drilling fluids. The upper trace depicts the characteristic gel profile of a clay-free IEF, and the lower trace is that of a traditional IEF.

When pumping resumes after a static period, the amount of time necessary for clay particles in traditional IEFs to break their bonds (gels) and revert to a fully flowing state is greater, resulting in higher ECD and downhole pressures. This is depicted in the lower trace of Fig. 1, where the gray area underneath the curve represents the total energy required to break the gel. This is much higher than that observed with clay-free IEFs, and this total energy is said to be associated with an increased risk of inducing losses to the formation.

Even though clay-free fluids exhibit a much greater propensity to generate gel strength, this does not lead to higher pressures and, consequently, to losses. The gel generation is rapid, and the breaking of the gels is equally rapid, validating the ability of this fluid to produce strong yet fragile gels. Clay particles require time to aggregate and develop Na+ bonds between each clay plate to generate viscosity. However, polymers are linear particles, which rapidly bond to one another without the need for aggregation. Consequently, the breaking of polymer gels is also performed extremely rapidly, meaning fluid stability is improved with respect to an overall reduction in stratification while improving the ability of the fluid to revert to a free-flowing fluid. This is important because this ability allows the fluid to reduce pressure spikes upon the application of force, whereas a large amount of force is required to physically break the Na+ bonds between the clay particles. That creates pressure buildup, which can lead to induced losses.

Norwegian Clay-Free Experience

Clay-free technology was introduced in the North Sea in the UK continental shelf (UKCS) in 2009, using the general global formulation that was devised for the Gulf of Mexico and adapted for use elsewhere. Because of environmental considerations, biodegradability of IEF additives is required in Norway. In 2012, a replacement for the primary viscosifier was identified and determined to be appropriate for use in Norway, following the required environmental tests.

Following several iterations, a fully formulated optimized fluid containing the new viscosifier chemical was compared with a standard clay-free fluid of equivalent density containing the “black” chemical. The rheology trace in Fig. 1 shows an excellent profile in the new fluid system characteristic of a low-ECD fluid, yet with reasonable low-end rheology for hole cleaning.

Field Observations on Fluid Performance

Offset and historical data indicated that the ECD, while not being restrictive, was still a major focal point that required careful monitoring. Throughout the drilling of a key section, great emphasis was placed on minimizing the ECD and ensuring it remained as low as possible. With respect to the main offset well, when comparing the ECD in the 16-in. section with the clay-free IEF, it was clear that there was much better ECD control obtained relative to that obtained with the traditional organophilic-clay-based IEF.

Drilling in the 16-in. section achieved a maximum rate of penetration (ROP) of 80 m/h; pressure-while-drilling measurements recorded no significant increase in ECD while drilling at this rate. However, this ROP was not sustainable because of waste-management restrictions, causing the ROP to be reduced to between 30 and 40 m/h. Nevertheless, this ROP was higher than anticipated.

The 12¼-in. section was also drilled much faster than expected. The 12¼-in. section was anticipated to take 11 days to drill and, because of offset experience, would include two bit trips. The ROP for this section was higher than anticipated; the section was drilled in 9 days. The section was drilled at an average of 33.4 m/h, with no hole-cleaning issues observed throughout the section. The main offset well required three bit trips to drill the section to final depth.

High-Pressure/High-Temperature (HP/HT)

In addition to the reduction-in-ECD contribution inherent to this fluid system, field experience has demonstrated excellent fluid stability of the clay-free systems. However, the temperature at the base of the 8½-in. section was estimated to be 160°C, which exceeded the highest temperature in which a clay-free technology had been used previously. Furthermore, on the previous HP/HT well drilled, excessive cold-temperature rheologies (CTRs) were experienced with the traditional HP/HT fluid used. The main concern was that this would mask the volume control in a critical part of the wellbore, an important safety issue that had to be addressed.

Thus, an optimized clay-free system was required for the HP/HT section that could

- Accommodate high solids loading

- Exhibit excellent high-temperature stability with respect to

>Rheology>Solids suspension

>Fluid-loss control

- Demonstrate improved CTR

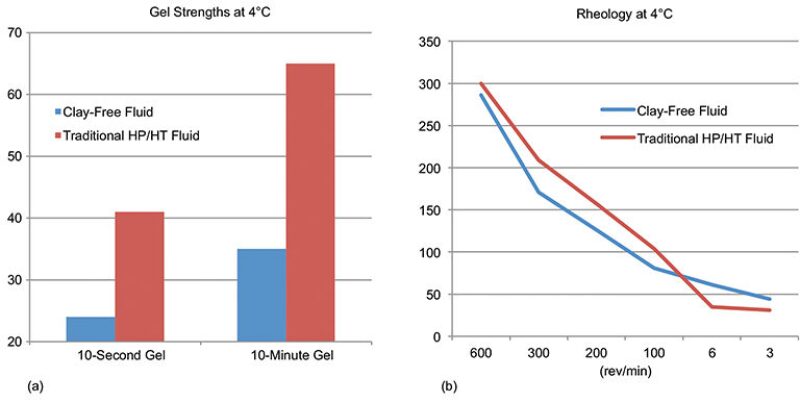

In Fig. 2, the worst recorded rheology profile of the clay-free HP/HT fluid used in the 8½-in. section can be observed to be improved significantly compared with that of the traditional IEF used on the previous HP/HT well.

A treatment was developed to allow clay-free fluids to meet and exceed the performance of organophilic-clay traditional fluids within a high-temperature environment and, equally importantly, improve upon CTR. This treatment was developed using experience gained from traditional HP/HT wells with organophilic-clay systems and from use of clay-free systems at lower temperatures. The main issue facing the original fluid formulation was that filtrate losses were excessive, generating an uncharacteristically high filtrate loss of 11 mL over 30 minutes. The treatment involved increasing the concentration of the filtration-control agent and adding a secondary emulsification agent to the fluid. This resulted in an improvement to the filtration-control properties of the fluid operation in a higher-temperature regime for an extended period of time.

This treatment reduced the filtration losses to a more manageable and much more characteristic 0.3 mL after 88 hours of static aging at 160°C. One of the primary concerns was to minimize the potential for excessive CTRs that could compromise operational safety. Superior CTRs have been realized with clay-free technology in other scenarios, but this had not been investigated fully for a clay-free HP/HT fluid. The preliminary optimization studies found improved CTR compared with traditional IEFs. In the field, the CTR was monitored constantly throughout the HP/HT section as drilling proceeded. In Fig. 2, the comparison between the clay-free- and traditional-fluid rheologies and gel strengths highlights the improved performance of the clay-free fluid. The gel strengths are significantly higher at 4°C than those observed with clay-free fluid. This highlights the ability of the fluid to ensure well control by limiting the masking of wellbore breathing by cold mud in the riser, an effect that was observed on the main offset well with traditional drilling fluids.

Conclusions

While this fluid was not designed for HP/HT environments, this application highlighted the potential for HP/HT use for clay-free technology. The chemistry designed for this fluid system exhibited a much more stable ECD profile compared with that of other IEFs. In the case of this project, no losses were observed at the 16-in.-casing shoe, which might not have been the case if an alternative organophilic-clay-based fluid were used. Furthermore, the easily broken gel strengths significantly reduced the risk of downhole losses, as demonstrated by a distinct lack of losses while drilling.

This article, written by Special Publications Editor Adam Wilson, contains highlights of paper SPE 166538, “Case History: Clay-Free Invert Fluid in Norwegian High-Temperature Well Provides Consistent Low ECD Profile,” by Mads Rødsjø, SPE, and Erik Akutsu, Det Norske Oljeselskap, and Steven Morris, SPE, and Renate Mikalsen, Halliburton, prepared for the 2013 SPE Offshore Europe Oil and Gas Conference and Exhibition, Aberdeen, 3–6 September. The paper has not been peer reviewed.