Sessions and speakers looked critically and hopefully at the North Sea industry, closely examining its many current and future challenges and presenting numerous scenarios and strategies for how it would survive and prosper. Some observers envisioned the North Sea sector strengthening the global oil and gas industry in the next half-century through continued production, the expanding resources of its supply chain, and the spread of its world-class expertise.

A plenary and 11 keynote sessions and the presentation of more than 100 technical papers and ePosters highlighted the conference, which also featured daily breakfast briefings and topical luncheons.

However, the event had a somber note. On 23 August, four offshore oil workers lost their lives when a helicopter flying them from their rig crashed off the Shetland Islands. Many of the presenters and speakers, including the Princess Royal, paid tribute to the four people and acknowledged the risks inherent in working offshore and the industry’s strong continuing commitment to safety.

Conference Chairman Malcolm Webb, chief executive of Oil & Gas UK, said that the United Kingdom oil and gas industry is the country’s greatest industrial success story in more than a hundred years and this year’s event served to underline that fact. “At the biggest Offshore Europe ever, we’ve addressed the key themes that will require industry focus to sustain activity in the UK Continental Shelf,” he said. “None of these is more important than safety.”

The Next Half-Century

Addressing the opening plenary session, the Rt. Hon. George Osborne MP, UK Chancellor of the Exchequer, stressed the continuing importance of the industry to the country.

“First, I recognize the vital role that oil and gas play in the UK economy and will continue to play for many, many years to come,” Osborne said. “Second, I also recognize that the oil and gas remaining in the UK Continental Shelf (UKCS) will be increasingly difficult and more expensive to extract, that this government commits to play our part in delivering the investment that’s needed. And third, I believe that the best way to support this industry and maximize the returns from this great national asset is by working together across the United Kingdom through mobilizing all of the UK’s resources and by pooling our risk to provide stability across the whole of the UK.”

Despite production having already peaked, oil and gas still meets about 70% of the country’s primary energy needs, and the oil and gas sector is the largest industrial investor in the UK, with a record level of investment projected for 2013, Osborne said.

The chancellor noted a government-announced program of tax incentives and tax relief intended to stabilize the UK industry’s long-term economic outlook, including

- Allowances for developing small fields, large deepwater fields such as those west of the Shetlands, and large shallow-water gas fields

- Allowances for extending the lives of brownfields

- Tax relief for decommissioning projects

Osborne said that oil and gas and renewable energy sources are essential to the UK’s future and the country “should not reject shale gas development. Britain is not going to turn its back on the energy sources of the future.”

Sam Laidlaw, chief executive of Centrica, said, “This is an industry that’s vital to the prosperity of many European nations. …. Here in the UK, offshore oil and gas exploration forms the bedrock of the sector, which supports nearly half a million jobs and makes a central contribution to the nation’s energy security, its economic growth, and the country’s tax revenue. But we must do all we can to safeguard its future.”

As an energy supplier, Centrica is seeing its global customer base becoming more dependent on natural gas, Laidlaw said. “Gas remains the most thermally efficient, cost-effective source of domestic heating” in the UK and “has an increasingly important role to play in power generation,” he said. “It’s cleaner than coal, cheaper than nuclear, and more reliable than wind. In the long term, we may well achieve the decarbonized power industry that we aspire to. But in the short to medium term, we will need gas to reconcile the aim of decarbonization with security of supply and affordability,” he said.

Laidlaw discussed four dimensions in which “the global energy landscape is already changing in quite radical ways.” They are

- Global oil and gas economics

- Trends in the North Sea

- The role of liquefied natural gas (LNG)

- Unconventional oil and gas

Futures markets in recent months have signaled a falling crude oil price trend, while the traditional linkage between oil and gas prices has weakened. “The result is that the marginal revenues of both oil and gas production are under pressure,” said Laidlaw, who stressed that cost competitiveness was vital to continued profitability.

In the North Sea, the demands of maintaining aging infrastructure as production declines have led to sharp increases in unit cost, leading to acute competitive pressures from other basins. However, “average field size, at least based on reserves, is still six times (that) of the Gulf of Mexico,” Laidlaw said. “With the right technology and incentives, there is much to play for.”

The growth of worldwide LNG capacity is globalizing the natural gas market, Laidlaw said. LNG imports to the UK have grown from zero 10 years ago to a level that can supply nearly a third of domestic gas demand. The growth of spot cargo shipping in a market traditionally built on fixed, long-term contracts will reduce regional price differentials over time and shift the producer’s emphasis from sales price to export cost efficiency, he said.

The future of UK unconventional oil and gas development is uncertain, but the economic benefit is potentially large, Laidlaw said. Whether the UK proceeds with unconventional development, other countries will and thereby will improve their resource pricing and supply security and attract energy-intensive industries. “Any drilling activities will need to be handled extremely sensitively,” he said. “The UK has the advantage of being able to learn from the US experience to ensure the industry is well regulated and that best practice is adopted. …. If we want to develop shale production successfully in the UK, we must listen and have meaningful engagement with local communities.”

In summary, Laidlaw said, “It is probably not an overstatement to say that we are experiencing a once-in-a-generation shift in global energy markets due to a variety of factors—LNG, shale production, and a new pricing dynamic. The key question is how the UK’s oil and gas industry responds to that shift.” Success will require an appropriate government policy framework and fiscal regime and the combined effort of the industry and its stakeholders to build capabilities, develop innovative technology, and lower the industry’s cost base, he said.

Andrew Gould, chairman of BG Group, emphasized the need for a stable, predictable government fiscal regime to ensure a successful future for North Sea oil and gas over the next 50 years. “The decade of the 2000s was plagued by rapid change in fiscal policies all over the world,” he said. “Fast-rising oil prices gave governments the impression they could increase their take without hurting the industry, but as the cost of extraction rose, this argument held less and less water. And nowhere was this truer than in the UK.”

While Gould said the current UK fiscal regime compares well with others and praised the latest reforms, he cited the refusal of the government to enter production sharing contracts with producers, except for decommissioning, as a key deficiency. “Companies are therefore vulnerable to any potential shift in policy and taxation of future governments,” he said. “And as the economics of the North Sea become increasingly marginal, this kind of field-life protection will become increasingly important.”

High operating costs have always been a feature of North Sea exploration and production, and the basin was “a technology frontier” when operations began 5 decades ago, Gould said. Today, as a mature basin, it largely faces increasingly marginal projects and complex geological targets along with greater competition from other global areas. “If the North Sea is to remain a competitive investment prospect, it must achieve a step change in the cost of exploitation, and such a change can only be achieved through massive changes in the methods used and the technology employed,” he said.

Improved technology will be needed in frontier areas for estimating hydrocarbon targets and recoverability and in mature fields to enhance recovery and reduce the costs of exploitation and eventual abandonment, Gould said. He cited a number of technological areas on which the industry needs to focus, including remote monitoring and control to reduce offshore personnel levels, increased subsea field recovery through improved intervention techniques and subsea separation and compression, and improved high-pressure/high-temperature (HP/HT) technology to aid frontier development. Gould said that the industry also will need to make more use of common shared infrastructure.

“The UK is a tremendous place for people to launch a business,” said Bob Keiller, chief executive of Wood Group. “The international energy marketplace is a fantastic market to target.” Companies that are passionate about the safety and welfare of their employees and workforces that interact with their operations are likeliest to succeed, he said. The durable relationships between supply chain companies and their customers make the North Sea oil and gas sector an attractive area for business.

Companies must continue to focus on social responsibility and ethical conduct, Keiller said. Supporting local communities is essential, through employment, payment of taxes and fees, community engagement and charitable activity, and minimizing the environmental impact of operations. Success depends not only on the flow of money, but also on company culture. Though the North Sea industry can attract talent, the challenge is how to change the culture so that people will want to stay.

“For companies to be successful for the next 50 years,” Keiller said, “they need to focus as much on not just what they do and what products they provide and what services they do, but how they go about it, how they conduct themselves in the business, and how they behave.”

Innovation will continue to be vital for the North Sea industry, he said, adding that the industry has the potential to create locally based jobs that can serve the global market beyond the life of the North Sea basin.

“The supply chain is part of the underdiscussed success story that is the UK oil and gas industry,” Keiller said. “I would argue that the supply chain is the unsung hero even within the sector.”

Record Numbers Attend OE 2013

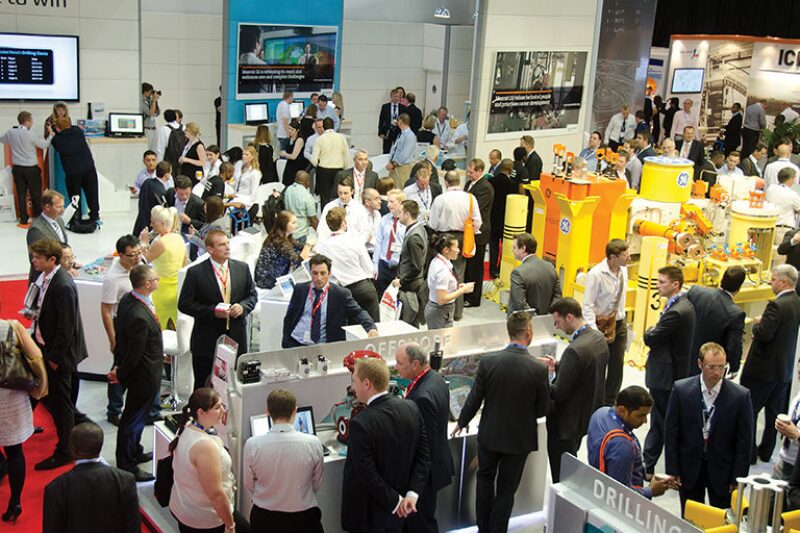

A record-breaking total of more than 63,000 people attended the SPE Offshore Europe (OE) 2013 conference and exhibition, surpassing attendance at the previous OE in 2011 by more than 25%.

The exhibition also set a record, with more than 1,500 organizations exhibiting. Twenty-two operating companies exhibited, the largest group of operators ever to take part, and 262 companies exhibited for the first time.

The 4-day event attracted a substantial number of small and medium-sized enterprises, many of them young companies, and a large number of innovative technologies and products were on display.

The global character of OE was well in evidence, as companies from 37 countries participated and there were 33 international pavilions. South Korea and Australia hosted pavilions for the first time. The exhibition filled six halls covering an expanded floor space of 27 217 m2.

The Global Opportunity

In a panel session on the opportunity for North Sea companies to become stronger global exporters of oilfield services, goods, and expertise, moderator Malcolm Brinded, chairman of the Shell Foundation, said that the North Sea sector is briefly in an advantageous position to achieve the goal.

Oil and gas supply chain opportunities exist in 80 to 100 countries, compared with about 20 countries 25 years ago, and the market could represent about USD 5 trillion in business between today and 2020, Brinded said. With US-based suppliers and contractors focused on a hot domestic market and their Chinese counterparts having yet to attain global technical and organizational competitiveness, “this is for European contractors and suppliers a unique decade of opportunity to really go for it,” he said. “By 2020, the US and Asian competition is going to be much harder to beat.”

Brinded and other speakers referred to “the North Sea brand” as an identity, based on the sector’s historic success in one of the world’s most challenging oil and gas provinces. “Our differentiator will be in the high-technology end,” he said.

Lord Green, UK minister of state for trade and investment, said that the North Sea suppliers of oilfield services, goods, and knowledge should “make sure that we find a way of bringing that broad base of expertise that we have got to the opportunities that exist around the world, where there is a hunger for the technology, the services, the skills, the knowledge about regulatory environments that we can share.”

Pieter Van Oord, chief executive officer (CEO) of Van Oord, a dredging, marine engineering, and offshore energy project contractor, provided a Dutch perspective on supply chain exports. Van Oord is chairman of IRO, the association of Dutch suppliers in the oil and gas sector.

Although the financial size of the Dutch oil and gas supply sector is difficult to measure, Van Oord said that it is at least EUR 5 billion and that it directly employs a workforce of 20,000. As a big industry for a small country, the sector has focused strongly on exports.

“Which firms are winning? I would say focused competitors; they grow fast,” Van Oord said. “This is not an industry for a jack of all trades. The industry is simply too complex.” Companies also are becoming bigger through consolidations, he said, and managing local content issues in international jurisdictions is increasingly important. “If you want to work in Australia, if you want to work in Brazil or Malaysia, you need local content,” he said. “So you need to find your local partners.”

Van Oord said that “safety is still an issue where we can make a lot of progress” and that companies need to be able to reject some projects. “The industry has been suffering from too many suppliers and contractors promising things which they could not deliver,” he said. Companies and their customers should allocate risks to the party best able to manage them and “where possible, strive for integrated solutions in the supply chain,” Van Oord said. Today’s largest risk for engineering, procurement, and construction contractors is managing the supply chain, he said, citing factors such as bankruptcies, labor issues, and quality concerns.

In conclusion, Van Oord said that Europe should focus on innovation, education, building reliable supply chains of big and small companies, and entrepreneurship.

Andy Inglis, chief executive of integrated energy services at Petrofac, said that much of his company’s international growth had occurred through the export of UK oil- and gas-related capabilities. Nonetheless, the industry in the UK and elsewhere is being challenged by internal demographics, with a disproportionate number of technical professionals expected to retire in the next few years, he said. And the challenge is accentuated by the shift in global reserves ownership toward the national oil companies (NOCs) and the addition of 2,000 oil fields worldwide over the past 10 years.

The UK industry has a long history in the North Sea basin and a range of technology development and expertise, particularly in the offshore sector, Inglis said. Since the Piper Alpha disaster in the late 1980s, the UK has developed safety standards and regulations that are “a benchmark across the industry” and UK offshore work practices are likewise an industry standard, he said.

“We have developed these systems that allow safe and efficient operations and the perpetuation of that from generation to generation,” Inglis said. “I find it fascinating as I go and meet our overseas clients, particularly the heads of the NOCs, that’s what they want to talk about first is ‘how do we get access to that learning?’ So I think the UK has a fantastic set of differentiators. The challenge now is how do we build on that expertise?” The next wave of innovation from the UKCS and the North Sea, he predicted, will come from decommissioning and wind energy projects.

Inglis said the industry had “a rather imperialistic view of the world” when he began his career more than 30 years ago. “I think one of the most important things we need to do is to adapt our style so that we deliver more with the grain of national agendas,” he said.

In Malaysia, Petrofac with a local partner developed an offshore gas field for Petronas under the first risked-services contract granted by the country. Petrofac has now turned the operation and its Malaysian workforce, which it trained, over to Petronas and is building a world-scale facility that will use UK standards to train 3,000 Malaysian technicians per year, “That’s what they want, that external accreditation of their technicians to our standards,” Inglis said. “So you can export the capability in a very tangible way.”

In Mexico, Petrofac has been working for more than 2 years under a services contract from Pemex to increase production from mature oil fields that had not received significant investment recently. “It’s a massive opportunity to bring our capability and expertise to these fields. And that’s what they’re looking for,” Inglis said. In the first two contracted fields, which Petrofac has operated for 18 months, it has been able to boost production by about 60%, he said.

Walter Qvam, president and CEO of Kongsberg, gave a talk titled “The Global Opportunity—The Only Opportunity.” Kongsberg, he said, had transformed in 30 years from a company doing business only in Norway to one operating in 25 countries with more than 80% of its business being international. The company has divisions in offshore oil and gas technology, defense, aerospace, and the maritime sector. Qvam said the pillars of its internationalization strategy are competence, integration, and collaboration.

To offer the best product to the global markets, “you have to have the right people—the best competence and the right competence,” he said.

Kongsberg is predominantly a software company and the ability to integrate technologies is increasingly important. With a growing abundance of technological products on the market, Qvam said, customers constantly ask “How do these things work together, how do they talk to each other?” Ensuring that its company products will communicate with third-party products is a daily challenge, particularly when proprietary technology is involved. However, integration goes beyond that to integrating resources, companies, and cultures, he said, “because a lot of our international expansion has been about starting up these local partnerships—on a very small scale actually.” Qvam described Kongsberg as “a melting pot of cultures.”

Collaboration is often a synonym for teamwork, but Qvam said it has additional meaning at Kongsberg. “We see that collaboration actually becomes more and more of a business model, because we are working with so many subsuppliers, so many technology companies that we are dependent upon,” he said.

Steve Swindell, chief operating officer (COO) of Xodus Group, offered a perspective on exporting by a medium-sized energy consulting firm. The Aberdeen-based company operates in eight countries with plans to expand geographically and in its technical scope.

“We cover a wide range of capabilities from subsurface drilling of wells to subsea flow assurance—a production facilities consultancy,” he said. “So we are not exporting hardware. We are not exporting systems or widgets or anything like that. The concept of global exporting (of) expertise is the issue here.”

The company’s philosophy is to build the right team. “Get the team and the work will follow,” Swindell said. “And it’s different from some organizations, especially the large contractors, where you go out and win a large job, and once you have, you then go out and find the people to do it.

“So how do you export that? Well, first, you’ve got to develop a brand and that takes time. …. You need money, you need lots of patience, and you need lots of help. And most of all, you need a market.”

It is important to have people with local knowledge, Swindell said, and sometimes it is necessary to buy expertise through a company acquisition. Another challenge for a company spread around the world is the ability to capture learning, so that learning gained in one location can be accessed elsewhere in the company. “We have had to put some effort into building systems which allow knowledge sharing—allow the people in our Dubai office and our Perth office to be able to access the knowledge and the learning activity in the UK,” he said.

Because people are different, “exporting doesn’t mean creating clones the world over,” Swindell said. “You have to build on the local cultures and expertise. And getting a good local partner is critical.”

Planning for the Long Term

In a session titled “Planning for Long-Term North Sea Drilling,” the outlook for North Sea oil and gas activity was examined in an overview and from the separate perspectives of drilling contractors and operators, along with a look at lessons learned from other industries.

Mike Tholen, economics and commercial director at Oil & Gas UK, an industry advocacy group, said that production in the UK North Sea had been falling by 7% to 8% per year for most of the past decade, and in 2011–2012 it began to drop at a 16% to 17% annual rate. “These are grievous numbers,” he said. As producers struggle to stem the decline, investment has risen to an all-time high of GBP 13 billion this year. Much of the new investment is going into new fields, with only a quarter of it directed toward existing fields, he said.

“There is a real tension between producing new stuff, which is taking time to come on stream, and getting more from the existing opportunities in the North Sea,” Tholen said. The situation is “something we want to see change in the next few years,” he said. Affecting this tension is the trend in rig lease rates, which have soared in recent years particularly because of the limited availability of rigs suitable for the North Sea. Increased drilling from existing production facilities could buffer that impact.

UK taxes on the industry also have risen. However, recent government actions, including tax relief for brownfield development, could help to shift the balance toward drilling in existing fields. The government “has done its bit,” Tholen said. “Now it is back over to the industry to find ways to manage and control costs, find ways to make these opportunities that are out there more attractive.”

Rod Hutton, senior manager of rigs at IHS Petrodata, said the UK North Sea rig demand was in a strong up cycle with 100% utilization of the semisubmersibles and jackups suitable for drilling in that market. In the central and northern North Sea, 16 to 17 semisubmersibles have been working, down from a peak of about 60 in the 1990s, Hutton said. In the North Sea jackup market, which includes the central and southern areas, 31 to 32 rigs are working, down from a 1990s peak of 40.

In the semisubmersible market, new rigs suitable for the northern North Sea are being built, but competition from other global markets such as the Caspian Sea is claiming a large majority of the newbuilds, Hutton said. Of 14 harsh environment newbuild semisubmersibles, only two rigs under long-term contract for the West of Shetlands area are slated for UK drilling. The average age of the UK central and northern North Sea semisubmersible fleet is 31 years, and these rigs can continue to operate for “only so long,” Hutton said. Of the semisubmersibles being built, most are high-specification deepwater rigs more suitable for the Norwegian than the UK market except for West of Shetlands, he said.

In the jackup market, of more than 100 new rigs being built, only 23 are targeted or could possibly come into UK service, and there is competition from other regions for many of those rigs, Hutton said.

By contrast, the Norwegian North Sea sector has seen nine new semisubmersibles come into service in the past 5 years, will see five newbuilds arrive in the next 2 years, and is experiencing solid growth in its jackup fleet, Hutton said. Much of the new demand stems from projects operated by Statoil.

The main difference in the UK and Norwegian markets is that “there is no UK equivalent of Statoil. …. There is no overarching state player dominating the market,” Hutton said. UK discoveries also tend to be smaller than those in Norway, he said.

“The cost of a newbuild semi for the UK North Sea is (USD) 450 million, and you can build a deepwater drillship for (USD) 600 million and contractors obviously aren’t going to go just for one market,” Hutton said. The drillship can serve multiple markets, many with larger discoveries such as east Africa and west Africa. “So, if they are going to spend that much money, they will spend on what they think will get more return,” he said.

Rig Sharing: A Solution?

A possible solution that could alleviate growing rig market pressures on the aging UK North Sea sector is a rig sharing program similar to the one operating in Norway. Geir Kristian Pedersen, managing director at Rig Management Norway, discussed his country’s experience with the program, in which operators work together to provide sufficient work between them for contractors and thereby secure long-term rig contracts covering multiple projects.

“Typically, the benefit, the most important one, is that the operators manage to secure capacity in a tight market even if they have few wells,” Pedersen said. “And from the rig owners’ side, they get more for their contract.” Generally, the service contractors remain the same throughout the long-term rig contract with the different operators.

“Then, the question is will this work outside Norway? I can’t see why not,” Pedersen said.

The Rig Contractors’ Views

Speaking for the rig contractors, Roddy Smith, executive vice president at Awilco Drilling, said that “the existing fleet has served us well” and offered a perspective on the future. Many units can stay in service for a long time with proper maintenance and renewal, but may have much shorter remaining lives, he said.

“The drilling and utilities package we can do wonders with,” Smith said, referring to maintenance and upgrades. “The hull is a different story.” Some will need steel renewal soon, while others can operate for many years without it. It is not simply a function of age, but often relates to the materials used to build the vessel, the quality of its construction, and how it has been used. “There are rigs built in the early 1990s requiring extensive steel renewal, and some built in the late ’70s requiring none,” he said. “It’s not one size fits all.”

Smith said that fleet renewal eventually will come, but that “a significant portion of the existing fleet in the UKCS” will remain in service “for at least the first half of the next 50 years.”

Mark Burns, executive vice president and COO at Ensco, said the current fundamentals of the global drilling rig market, including the North Sea, are very strong. While Norwegian and UK production has greatly declined, “All this means increased oil and gas drilling activity, increased service company activity, and also increased operator activity,” he said.

A serious challenge facing the industry is “the competition for experienced personnel,” Burns said. “This is a wonderful time for a young man and young woman to get into this industry.” A further challenge is the supply chain, which is “very tight,” he said.

In closing, Burns said, “As we continue to experience this increased activity, as an industry we must guard against complacency.”

Gavin Sutherland, UK country manager at KCA Deutag, discussed his company’s commitment to North Sea drilling. “We’ve never shifted from the North Sea. We’ve held it as one of our main areas of operation,” he said, noting that it has been a stable work environment for the company’s crews. Activity is “picking up” with contracts typically of 2 to 5 years continuing to provide stability, he said.

“The UK drilling industry is perceived to be in decline,” Sutherland said. “Well, I would challenge that at the moment. We’ve been operating four, five, six strings over the last 3 to 4 years and we are headed to eight or nine operating strings.”

The activity is increasing the demand for personnel, and new drilling units coming into the North Sea in the next 2 to 3 years do not yet have crews, he said.

“We need to make sure that (the North Sea) remains an attractive proposition for drilling contractors,” Sutherland said. He called platform drilling “a low-margin business” and said the differentials between UK and international contractor terms are increasing as competition from other areas intensifies.

Kjell Jacobsen, a partner at Energy Ventures Norway, said a new semisubmersible rig would cost USD 500 million or more to build, an amount that with current high demand could be recouped in about 5 years.

“There are a lot of rigs being built, but unfortunately …. they are not suited to work here (in the UK),” he said. “They are ‘overspecced,’ too expensive, and too heavy.”

Jacobsen said a number of steps are needed to reduce investment risk so that more newbuild semisubmersibles could enter the UK market. Building against long-term contracts would eliminate market risk and there are strategies that could reduce capital spending risk, he said. Financial risk could be reduced by long-term lease structures and various credit strategies, and in operating risk, “there are a lot of things to do with the way risks are shared.” If various measures such as these are taken, “there is significant scope to make an investment in that drilling rig and get an acceptable risk-weighted return,” Jacobsen said.

Other Industries’ Examples

James Pearce, partner at AT Kearney, discussed how other industries had successfully dealt with similar issues and gave examples from the automotive and chemicals/lubricants industries.

In the automotive industry, the original equipment manufacturers (OEMs) and parts suppliers were investing ahead of demand. When the 2008–2009 financial crisis hit, the OEMs aggressively cut orders and caused turmoil among the parts suppliers with a number of them filing for bankruptcy. With the market recovering, the suppliers are investing more slowly than the OEMs, Pearce said. They “don’t want to be burned” as they were during the recession, he said.

In the lubricants sector of the chemicals industry, tougher emissions regulations and Asia’s expanding use of motor vehicles has increased demand for high-specification motor oil. Base oil manufacturers, who sell their product to oil blenders, are faced with the strategic question of investing more in manufacturing or keeping supplies tight to raise prices.

Pearce said there are four lessons the oil industry could take from the responses of both the automotive and chemicals/lubricants industries to growing demand amid substantial market risk. The lessons are to

- Create a strong demand forecast in which operators and their suppliers can have confidence.

- Collaborate and communicate. Operators should share that forecast with existing and likely suppliers, including criteria for triggering new investment and a view of what others are doing.

- Agree on a capacity addition strategy covering capacity added physically or through improved efficiency.

- Consider creating risk-sharing contracts with suppliers.

The challenge of the North Sea oil sector is “to secure the capacity for the mutual industry and national benefit,” Pearce said. “Because historically, we have been a cyclical industry—we’ve been short-termists—and the danger is now, with the small satellite fields and with the aging health of the infrastructure, that if we don’t do the infill drilling and get the oil out of the ground now, then it will be to the detriment of everyone.”

The Operators’ Views

Rob Buchan, Aberdeen general manager at GDF Suez, represented the viewpoint of an operator in the central and southern North Sea that uses jackup rigs. He spoke on safety, the workforce age gap, and industry cooperation.

“Wells are becoming more challenging, with deepwater, high-pressure/high-temperature, and extended-reach drilling becoming the norm,” Buchan said. “Compounding this problem is the age gap. And this is an issue the industry is already facing both offshore and onshore with both contractors and operators.”

“The industry today is extremely busy,” he continued. “And the labor market is very buoyant; it’s extremely volatile. Experienced personnel are already becoming very hard to find. And without acknowledging this problem and dealing with it, we as an industry face the consequences of increased safety and financial risk.”

The future lies in “capturing and sharing experience and knowledge, mapping and sharing competencies, sharing rigs” and jobs based on long-term rig contracts using the same crews over long periods. Buchan said he also looked ahead to “newer, more flexible drilling units operated with less people, with less risk, and with a lower cost base. Operators and contractors need to work together to find a way of supporting each other to make this happen.”

Peter Jones, managing director for UK at Taqa Bratani, represented the viewpoint of a northern North Sea operator that uses semisubmersible rigs. He addressed the difference between the UK and the Norwegian markets, particularly the larger number of newbuild semisubmersibles that will come into Norwegian as opposed to UK waters in the next 5 years. The key difference is Statoil, which “has played a huge role in facilitating that,” Jones said.

“Things have to change if we’re going to have a sustainable North Sea” oil sector in the UK, Jones said. “We do not have a Statoil to solve it for us.”

Listing the strains on the UK market, Jones mentioned global competition for newbuild rigs, dilution of workforce skills and experience, rising well costs, increasing well complexity, and an aging fleet that is drilling wells “on the edge of capability.” As a result, “the margin of error is getting tighter and tighter,” he said. “So if things go wrong, you end up with much more expensive wells.” This, he said, goes back to the scenario of the declining UK production that Tholen presented.

“So the challenges are definitely there,” Jones said. “The rig market is very active. We have about 100% utilization. But potentially in the UK, with the exception of the two rigs in the West of Shetlands, it’s a short-term view. We’re only looking out 2 or 3 years, and as Kjell pointed out, the newbuild decisions are at a minimum 5 (years).”

Finally, Jones said, “How can we facilitate a solution, whether it’s through … an entity without a financial interest or downright better cooperation between operators and drilling contractors? We have to find a solution if we are going to have a sustainable industry over the next 50 years. We really have to.”