Universities are working hard to anticipate the demand for new technologies and techniques as oil and gas exploration delves into deeper waters, harsher climates, and unconventional fields. Numerous universities are teaming up with the industry on projects such as modeling software, heavy oil technologies, fines migration, drilling technologies, and foam to enhance oil recovery and production. Through these research collaborations, more efficient methods are being developed to meet the increasing global consumption of oil and gas.

Petroleum Engineering Department, Colorado School of Mines, US

The Petroleum Engineering Department at the Colorado School of Mines has a large undergraduate and graduate enrollment and a healthy mix of multidisciplinary research efforts including the Unconventional Natural Gas and Oil Institute; the Marathon Center of Excellence for Reservoir Studies; the Fracturing, Acidizing, Stimulation Technology Consortium; the Energy Modeling Group; the Unconventional Reservoir Engineering Project; and the Physics of Organics, Carbonates, Clays, Sands, and Shales Consortium.

One area of focus is the Routes to Sustainability for Natural Gas Development and Water and Air Resources project in the Rocky Mountain Region. For this project, the Petroleum Engineering and the Civil and Environmental Engineering departments are working with their sister school, the University of Colorado at Boulder, and seven other institutions in a Sustainability Research Network (SRN) funded by a 5-year grant from the US National Science Foundation. The mission of the SRN is to provide a logical, science-based framework for evaluating environmental, economic, and social trade-offs between the development of natural gas resources in the Rocky Mountain Region and the protection of water and air resources. The SRN plans to give the results of these evaluations to the public in a way that will improve policies and regulations governing oil and gas exploration. “Our goal is to find the balance between maximizing the development of natural gas and oil resources for the benefits of short-term reduction of CO2 emissions from power generation and transportation, national energy independence, and national job growth, while minimizing damage to water and air resources and risks to human health,” said Joseph N. Ryan, faculty director of the research project.

The department’s first task in the SRN is to assess the isolation of aquifers from gas- and oil-producing formations. The department is evaluating the possibility of losing isolation because of damage to the cement sheath from pressure testing, casing integrity tests, and other operations during the production cycle of an oil or gas well over a life cycle of up to 50 years. Using finite element analysis, the SRN is assessing the effects of the change in the in-situ stresses acting upon a cemented wellbore to determine the improvement or degradation of the annular seal during the well’s life cycle.

The second task is to estimate the probability of casing and cement sheath failure in production, intermediate, and surface casing strings. As part of this task, the SRN will review the consequences of failures, including volumes and nature of gases and fluids released into an aquifer. They will focus on “black swan” events—unlikely, worst-case scenarios and the possible effects of such an event.

The third task is to examine the possibility of fracturing into aquifers using fracture modeling software in addition to finite element modeling. The modeling will involve combinations of casing, formation barriers, and annular cement to determine if fractures could propagate into freshwater aquifers under a variety of conditions. The fourth task is to evaluate procedures used by various operators and service companies for “green” vs. “nongreen” well completions. The results will determine the best practices for green completion operations.

The broader impacts of this effort include improved public understanding of the effects of natural gas development on water and air resources and better decision making regarding the local effects as well as regional and national benefits of natural gas development.

Institute of Drilling Engineering and Fluid Mining, Technical University Bergakademie Freiberg, Germany

The Institute of Drilling Engineering and Fluid Mining at the Technical University Bergakademie Freiberg was established in 1962 within the Faculty of Geosciences, Geoengineering, and Mining. The university offers a German diploma, which is equivalent to a master of science, in petroleum engineering. The curriculum covers engineering fundamentals and advanced subjects in drilling and production engineering as well as renewable and sustainable energy, including geothermal energy and underground storage of hydrocarbons, hydrogen, and CO2.

The institute has strong ties with the oil and gas industry through its association with oil, gas, and service companies and SPE chapters in Europe and around the world. Before joining the institute, faculty members work for a number of years to gain real-world experience in the industry. They maintain their connection with the industry by consulting, working on joint research projects, and teaching short courses.

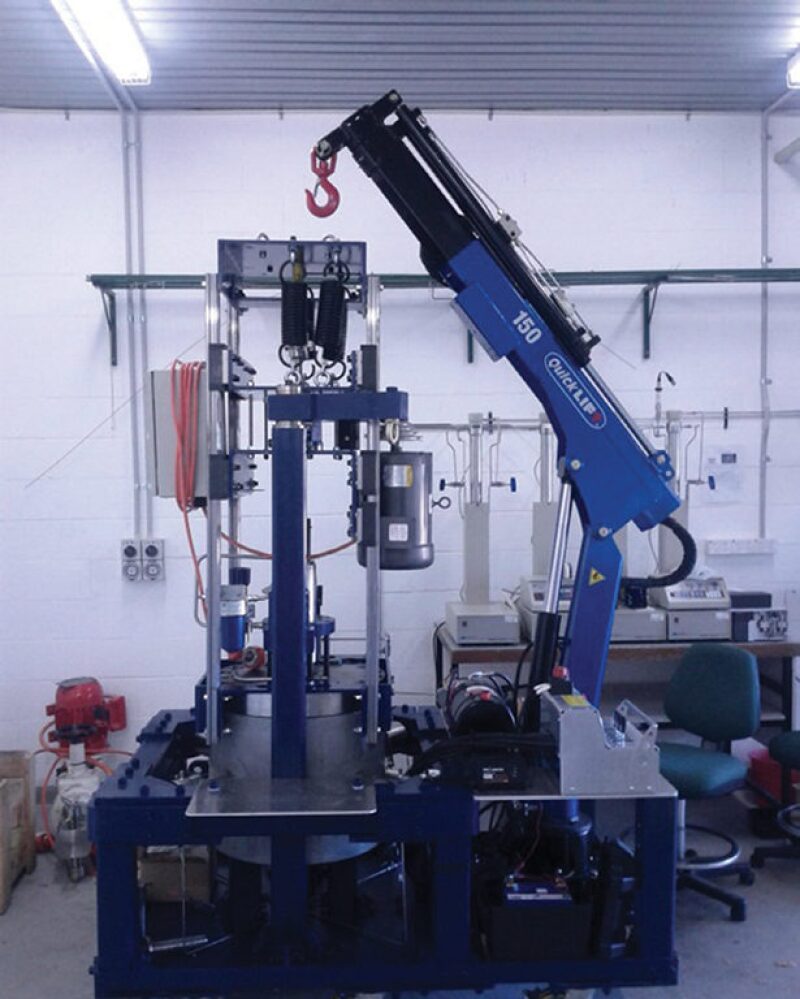

The institute’s laboratories are fully furnished with the latest equipment and software. They have specialized equipment and advanced experimental setups for research in drilling fluids, oilwell cementing, data transmission in boreholes, and enhanced oil recovery. In particular, the laboratories have sophisticated equipment (Fig. 1) to measure the permeability of very tight rocks, such as caprock and rock salt, which are harder or more resistant rock types that often lay over a less resistant rock type. In 1919, the university took over the Reiche Zeche mine, which consists of 14 km of passageways at depths up to 230 m. The mine provides unique opportunities for research projects that require these specific conditions.

- Current R&D projects include the following:

- Ultrahard materials for drill bit bodies and cutters

- Seismic prediction while drilling

- Hydraulic and acoustic high-speed telemetry systems

- High-pressure/high-temperature return permeability tests and drilling fluid management

- Energy fluid storage in salt caverns and porous reservoirs

- Stimulation technologies

- CO2 storage in porous reservoirs

- Enhanced oil recovery (e.g., microbial, thermal, and acoustic wave stimulation)

Other major research interests include geothermal reservoirs and unconventional reservoirs, such as shale gas and submarine hydrate reservoirs.

Institute of Petroleum Engineering, Heriot-Watt University, UK

Research activities at the Institute of Petroleum Engineering at Heriot-Watt University span from exploration, through reservoir appraisal and development, to production technology. Within this broad spectrum, the institute is divided into 12 distinct research themes, each represented by an interactive grouping of academic/research staff and postgraduate research students. These themes include carbon capture and storage; enhanced hydrocarbon recovery; petroleum geoscience; and gas hydrate, flow assurance, and pressure/volume/temperature.

The Gas Hydrate, Flow Assurance, and Phase Equilibria Pressure/Volume/Temperature Research Group consists of approximately 20 staff and students with expertise in chemical engineering, petroleum engineering, geology, and physics. The research team seeks to address various aspects of flow assurance and gas hydrate development, including kinetic hydrate inhibitor evaluation; avoiding gas hydrate, wax, and asphaltene problems in petroleum production and transportation; design and testing of low dosage hydrate inhibitors, hydrate monitoring, and early warning systems; and the natural occurrence of hydrates in sediments.

The research group’s activities are supported by the Centre for Gas Hydrate Research, which was formed in 2001, and the Centre for Flow Assurance Research, which was formed in 2007. The research group collaborates with the industry through four joint industry projects and receives support from 25 companies. Current research is being developed through five ongoing projects: gas hydrates and flow assurance; reservoir fluid studies; low dosage hydrate inhibitors; hydrate safety margin monitoring and early detection systems; and impact of common impurities on CO2 capture, transport, and storage (a collaborative project with Mines ParisTech). Research activities have resulted in generating new understanding, novel experimental data, and extensive test facilities including five well-equipped laboratories and have led to more than 200 papers published in peer-reviewed journals and presented at technical conferences.

To address the increasing industrial demand for technical support, Hydrafact, a Heriot-Watt University spin-off company, was formed in 2006. The company is based in the Heriot-Watt University Research Park and has eight full-time and seven part-time staff members. Results of studies by the Gas Hydrate, Flow Assurance, and Phase Equilibria Pressure/Volume/Temperature Research Group have led to the development of three tools that are being commercialized by Hydrafact under license from the university: HydraFlash, HydraChek, and HydraSens.

HydraFlash consists of comprehensive software capable of modeling a wide range of scenarios in reservoir fluid systems. It can be used by chemical, process, reservoir, and production engineers for a variety of phase equilibrium calculations, covering systems with and without gas hydrates. The software is currently being used by a large number of oil, gas, and service companies. HydraChek and HydraSens are being developed as joint industry projects. HydraChek monitors hydrate safety margins by providing the actual concentration of hydrate inhibitor and salt through downstream analysis of produced water samples. This information can be combined with operating parameters to allow the operator to continuously monitor and optimize inhibitor injection rates. HydraChek has been successfully deployed in many fields around the world, and an online version is being developed by Hydrafact with support from Total E&P UK and Statoil Petroleum. HydraSens detects early signs of hydrate formation in hydrocarbon production systems by analyzing compositional changes in produced gas to detect small amounts of hydrate forming.

Petroleum Engineering Program, Petroleum Institute, Abu Dhabi

Although the Petroleum Engineering Program at the Petroleum Institute is relatively new in the region, it has become regionally and internationally known because of its staff, undergraduate and graduate students, and state-of-the-art laboratories. Accredited by the Accreditation Board for Engineering and Technology, the program offers master of science and master of engineering degrees and has plans to offer a doctoral program in the near future.

The program offers a wide range of technical courses with a focus on applied engineering and decision-making tools to prepare students for global challenges in the energy sector. It benefits from direct access to real field data and examples through its strong affiliation with Abu Dhabi National Oil Company (ADNOC), and other companies, including Shell, BP, Total, and Japan Oil Development.

The program has several major projects with industry collaboration, one of which is the Smart Water Flood Project funded by Abu Dhabi Company for Onshore Oil Operations (ADCO) and led by Hemanta Sarma. The aim of this project is to increase oil recovery by altering formation wettability through modification of the chemical composition of injected water in the reservoir. A second project is the Transition Zone Project led by Hadi Belhaj. Also funded by ADCO, the project focuses on investigating variation of oil saturation distribution in a complex reservoir and determining the optimum well completion mechanism. Funded by ADNOC and Total, Ali AlSumaiti leads a project on digital rock physics in collaboration with Mohammed Sassi from Masdar Institute. The main objective of the study is to develop a digital rock physics database for Abu Dhabi’s reservoirs to be used as a tool to generate accurate, fast, and cost-effective special core analysis properties. This tool will ultimately support reservoir characterization and simulation models. The program also collaborates on projects with partner universities, notably Stanford University, the Colorado School of Mines, The University of Texas at Austin, and Rice University.

Continuous global growth in the demand for oil and gas has ignited the drive to explore new opportunities and develop new technologies to meet the demand. Carbonate reservoirs in the United Arab Emirates are categorized as high-pressure/high-temperature with great heterogeneity and high acidity. As a result, ADNOC, in conjunction with the institute, will build a new research and development (R&D) center called the Petroleum Institute Research Center with the aim to solve these issues. The advanced laboratories have been designed to meet all technical challenges and health, safety, and environmental compliance. The research center is expected to be complete by the end of 2014. With this addition, the institute expects that the number of funded projects will increase rapidly as will the number of scholars with extensive industry and academic experience to work on these projects.

Australian School of Petroleum, University of Adelaide, Australia

The Australian School of Petroleum at the University of Adelaide offers education, training, and research in the upstream petroleum industry. The program integrates petroleum engineering, petroleum geoscience, and business decision making in one school. Its current research interests are

- Reservoir characterization, modeling, and simulation

- Unconventional resources, completion, and production techniques

- Fundamentals of flow in porous media, enhanced and improved oil recovery, formation damage, and geomechanics

- Sedimentology and stratigraphy

- CO2 sequestration

- Economic evaluation

- Decision making and risk analysis

The school has well-established links with the petroleum industry and related government organizations. It is a node of the Cooperative Research Centre for Greenhouse Gas Technologies, a collaborative research organization focused on CO2 capture and geological sequestration.

One of the school’s key research projects involves fines migration-assisted technologies for oil and gas recovery. Very small particles called fines can drift and block the permeability of the well. This process, known as fines migration, may result from an unconsolidated or unstable formation or from using an incompatible fluid that frees the fines. This is the most common formation damage mechanism that often challenges the economic viability of a petroleum development project and is often found in production and injection wells, drilling, waterflooding, and pressure depletion with water support.

Although the current theory of fines migration in petroleum reservoirs predicts a delay in the permeability response, laboratory tests demonstrate an instant response. A new theory developed at the school involves the maximum fines retention function and drift velocity for fines that model fines mobilization and allows for laboratory coreflood test interpretations, well impairment history analysis, and well behavior prediction. Laboratory and field case studies validate the new approach. The reservoir studies use corefloods, tests with rock fragments and cuttings, Z-potential, and scanning electron microscope data along with well history for reliable prediction, prevention, and mitigation of productivity decline.

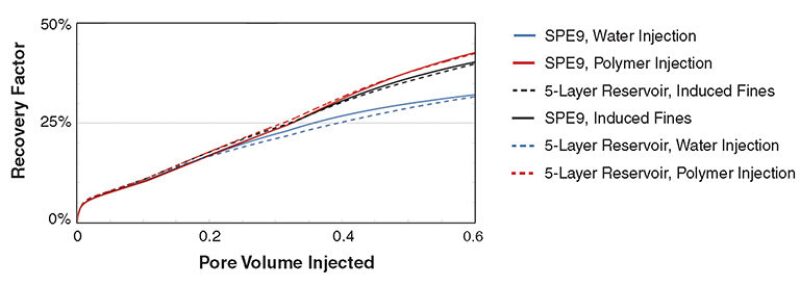

Traditionally, fines migration has been avoided because of its potential for having a harmful effect on reservoir permeability. However, research suggests that the permeability decline effect provides a relatively simple method for water mobility control. The university proposes deliberately freeing natural reservoir fines by injecting low-salinity/high-pH water, which results in a decline in the reservoir permeability and a subsequent deceleration of the injected or invaded water. Laboratory and field data cases demonstrate a threefold to fourfold reduction in produced water and a 5% to 10% increase in the recovery of oil and gas (Fig. 2), indicating that natural or deliberately induced fines migration may significantly assist in oil and gas production.

Center for Petroleum Studies, State University of Campinas, Brazil

The Center for Petroleum Studies (CEPETRO) was founded in 1987 in a partnership between the State University of Campinas and Petrobras to address an increasing demand for R&D in the oil and gas industry. With this partnership, the Department of Petroleum Engineering in the Mechanical Engineering College was also created along with a master’s-level petroleum engineering program.

CEPETRO facilitates collaboration between academic and industry professionals to find new knowledge and technologies for the sector and to contribute to the scientific and technological development of the oil and gas area in Brazil. During its 25 years of existence, CEPETRO has carried out more than 300 applied research projects and has had approximately 390 master’s and doctoral graduates.

Research is the flagship of CEPETRO activities. The center currently has 140 researchers with expertise in oil and gas involved in 65 financed research projects. The center’s infrastructure includes six laboratories on its premises and another 13 laboratories in institutes and colleges around the campus. Current research is concentrated in six fields in

- Reservoir characterization

- Well engineering

- Computational geophysics

- The production of oil and gas

- Reservoir engineering

- Riser systems

CEPETRO’s reservoir characterization research focuses on investigating reservoirs from the microscopic scale (e.g., petrophysical features) to the macroscopic and megascopic (e.g., geometry of bodies and architecture) scale, which includes the petrographical characterization of field rock samples and outcrop analogs; field investigation of electric, radioactive, and magnetic properties; and diagenesis, the study of chemical and physical changes to sedimentary rock after formation.

Research in well engineering covers basic and applied aspects of wellbore stability, directional wells and new techniques for drilling, well control and safety, operability of ships and drilling rigs, and production in harsh environmental conditions. Computational geophysics research involves the development and application of methods and algorithms linked to wave propagation. Seismic processing algorithms, such as image reconstruction and inversion of seismic data, are being studied to better understand reservoirs.

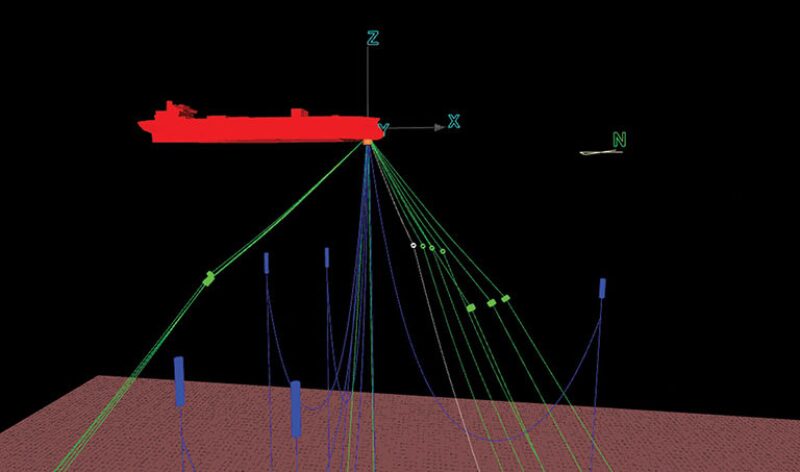

Oil and gas production research facilities, such as CEPETRO’s multiphase flow lab, focus on new techniques and technologies that improve production and flow assurance in onshore and offshore fields, while reducing cost through intelligent production management (Fig. 3). The main research projects in oil and gas production cover artificial lift, separation of gas/liquid/solid, use of intelligent systems, and the production and transportation of heavy oils.

CEPETRO’s research in reservoir engineering involves characterizing rocks from basic and special core analysis with a focus on fluid displacement mechanisms and their effect on reservoir rocks. Analysis is conducted through laboratory assessments of the rock fluid properties as well as reservoir modeling through deterministic and geostatistic techniques. Reservoir simulation research is a primary focus, covering topics ranging from history matching core displacement studies to field production data.

In the study of subsea systems, operability issues in offshore rigs, subsea operations, and information processing during the drilling and intervention phases are studied. CEPETRO aims to investigate and develop techniques related to subsea production systems, subsea equipment, subsea pipes, and production risers. CEPETRO’s previous R&D projects have included the design and installation of template manifolds, floating production systems with dry completion, numerical and experimental analysis of hybrid riser system dynamics, and the life of steel catenary risers.

Alberto Luiz Coimbra Institute for Graduate Studies and Research in Engineering, Federal University of Rio de Janeiro, Brazil

Historically, the Alberto Luiz Coimbra Institute for Graduate Studies and Research in Engineering (COPPE) program at the Federal University of Rio de Janeiro (UFRJ) has had a strong R&D emphasis on petroleum engineering. The first joint effort between Petrobras and UFRJ was formed in 1977; this was invigorated by the discovery of huge deepwater reserves along the Brazilian coast and more recently in the pre-salt layers. These efforts have led to the creation of jobs and consulting projects as well as the production of several scientific articles. This year marks the 10th anniversary of the installation of the world’s largest ocean basin laboratory, which was designed and built by COPPE. The COPPE petroleum interdisciplinary program draws upon talent from several departments and laboratories including petroleum systems, offshore systems and structures, structural integrity, materials, dynamic positioning, submarine robotics, and computational systems.

Petrobras America, a subsidiary of the Brazilian state oil company, has been operating the Cascade and Chinook fields in the US Gulf of Mexico. The company deployed one of the world’s deepest floating production, storage, and offloading (FPSO) facilities—the BW Pioneer FPSO facility. During the review of these field developments, what was then known as the US Bureau of Ocean Energy Management, Regulation, and Enforcement required the continuous monitoring of mooring tension in the mooring system. To meet these requirements, Petrobras America contracted a primary monitoring system to directly measure mooring system tensions using gauged pins. However, an alternate monitoring system was also required to indirectly determine tensions by measuring the FPSO’s turret.

For this, Petrobras contracted COPPE/UFRJ to help develop the alternate system. Calibrated numerical models were created to represent the mooring system, which were then analyzed by the numerical solver SITUA/Prosim, which was developed by COPPE and the Laboratory of Computer Methods and Offshore Systems in partnership with Petrobras (Fig. 4).

Considering the platform would incorporate a supervisory system to collect and store measured data (e.g., positions, tensions, sea states), the tasks assigned to COPPE/UFRJ included adapting the analysis software for offshore use and real-time processing of the measured data to calculate and record the line tensions.

The most critical task was building an accurate model of the existing mooring system. The tension data from the primary monitoring system was unreliable, so alternative calibration procedures were devised. Remotely operated vehicles were employed to provide position data for selected points along the lines, and this data was post-processed into an accurate representation of each mooring line.

Because it needed to operate continuously and without supervision, the alternate monitoring system had to also be fault-tolerant. Currently, the system is operational and working without interruption. The model can also be recalibrated and updated with new data from surveys or direct monitoring of the mooring system tension.

Department of Petroleum Engineering, Delft University of Technology, The Netherlands

The Department of Petroleum Engineering at Delft University of Technology joins its fellow geoscience disciplines (geology, geophysics, petrophysics, geoengineering, and resource engineering) in the Department of Geoscience and Engineering. The petroleum engineering group has seven staff members, 25 to 30 doctoral and postgraduate students, and approximately 50 master’s-level students.

The department collaborates with subsurface disciplines, mathematics, and mechanical and chemical engineering. Cross-disciplinary research efforts include the close integration of geology, data assimilation, and reservoir engineering in reservoir characterization and the use of geophysics to monitor recovery processes and production from unconventional hydrocarbon resources. The department emphasizes innovation and complex experimental studies through its large and well-staffed laboratory. The department focuses on optimization and control theory applied to reservoir management, enhanced oil recovery, numerical methods of reservoir simulation, well productivity, and fundamental fluid and transport properties in porous media.

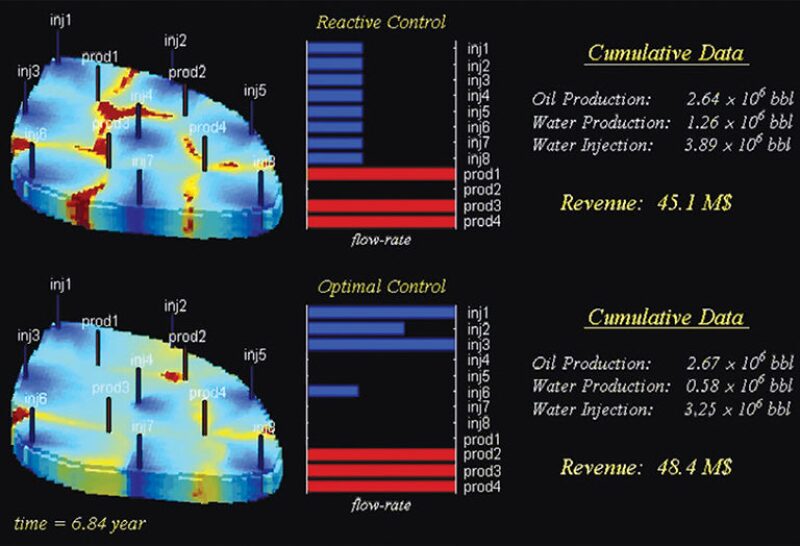

The department has been a pioneer in the development of concepts and techniques for “closed-loop reservoir management” also known as “smart fields” (Fig. 5). This involves optimization under uncertainty, data assimilation, and model order reduction. Two of the program’s key innovations in this field are the introduction of adjoint-based, robust, and two-level techniques for smart well optimization and of model reduction techniques. “Moreover, we have established fundamental insights in controllability, observability, and identifiability of reservoir flow, which serve as the basis for better algorithms for data assimilation and model-based production optimization,” said Jan Dirk Jansen, professor of reservoir systems and control.

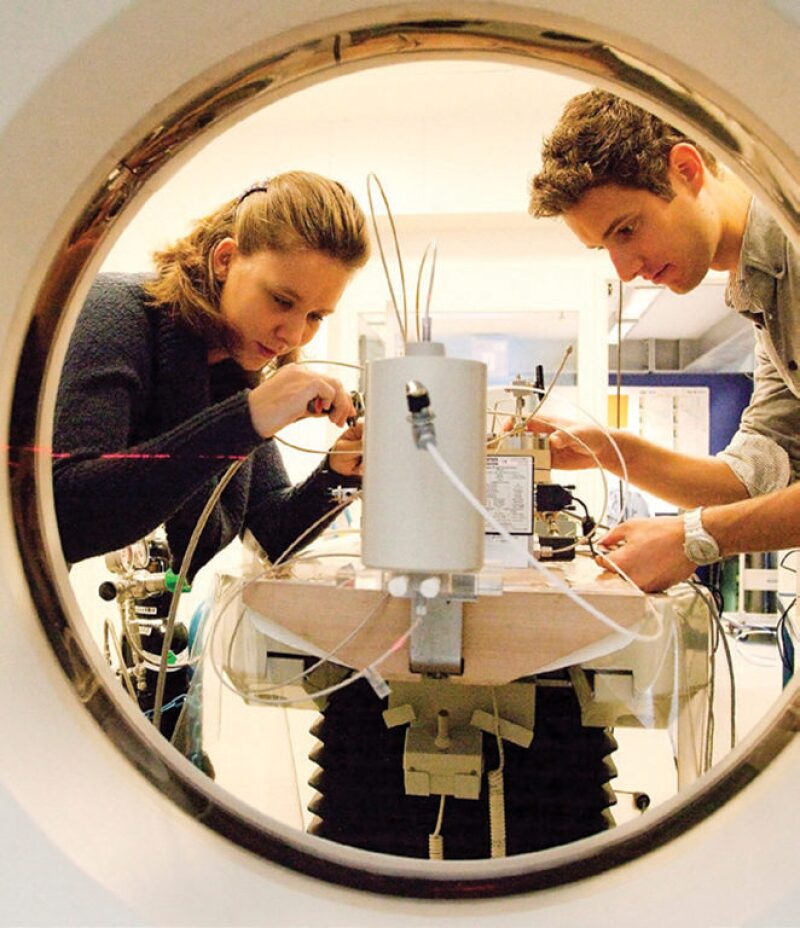

In the field of enhanced recovery, foam piques the interest of Delft University researchers. “The complex fundamental properties of foam make it an excellent candidate for improving sweep of injected gas and production of oil during injection of gas for enhanced oil recovery,” said Bill Rossen, professor of reservoir engineering and chair of the petroleum engineering program. Foam research is divided into two themes: (1) developing improved experimental methods for its characterization and (2) improving modeling of the process based on insights from the characterization methods. Researchers develop more sensitive techniques for displacement experiments with foam using computerized tomography (CT) scans (Fig. 6). A new way to interpret CT data compared with prior techniques reduced the estimate of the flowing gas fraction in foam by a factor of 70. Researchers also explore the effect of oil on foam in oil recovery. Chemically enhanced oil recovery research includes experimental studies and modeling of polymer flooding, alkali-surfactant polymer, and alkali-surfactant foam.

As part of a major CO2 storage research program in The Netherlands, the department focuses on transportation, reactions, phase changes, and petrophysics as well as how they affect the feasibility of CO2 sequestration in aquifers and depleted oil and gas fields. Micro-CT visualization revealed that during CO2 injection, salt precipitates at discrete locations distributed throughout the porous sample. Precise measurements of contact angles show that CO2 replaces water as the wetting phase on coal and some other minerals at high pressure.

Department of Petroleum Engineering, Curtin University, Australia

Located in Perth on the west coast of Australia, Curtin University’s Department of Petroleum Engineering is at the hub of Australasian oil and gas production. The department offers bachelor’s, master’s, and doctoral programs in petroleum engineering and will begin a new 2-year master of subsea engineering program in 2014.

Closely aligned with the oil and gas industry, the department has a number of research projects with international companies including Chevron, Shell, Woodside Petroleum, and Apache as well as local Australian companies including Buru Energy and NorthWestern Energy. The department also works alongside the government, mostly with improving CO2geosequestration (retention and wettability issues) and future drilling technologies. Curtin has four main areas of research in

- Reservoir engineering for understanding pore fluid flow

- CO2 geosequestration

- The geomechanics of fracture systems associated with shale gas

- High-speed, low weight-on-bit drilling technologies

In association with Deep Exploration Technologies Cooperative Research Centre concepts, the department anticipated that a future need of the industry is for a fast but inexpensive, high-technology drilling rig that can later be applied to shale gas fields and conventional oil and gas fields. The rig would need a small footprint to initially support rapid hole drilling to 2 km in the hard rock industry. To meet this need, Curtin developed a concept using a high-speed (6,000 to 8,000 rev/min), low weight-on-bit coiled tubing rig with a high-speed downhole turbine driving a diamond impregnated bit. The coiled tubing is made of a light composite material and has imbedded sensors along its length for logging while drilling. The rock is inserted into a true triaxial cell that takes a maximum of 1 cu ft of rock to provide realistic downhole stress conditions (Fig. 7).

A CO2 storage project funded by the Australia National Low Emission Carbon Scheme seeks to better understand the effects of supercritical CO2 on the reservoir and shales for long-term storage of CO2. Of particular significance to carbon storage is the issue of imbibition and wettability, which allows improved reservoir simulation of the process. In parallel with this project, a second project seeks to understand the dehydration effects of CO2 when in long-term contact with impervious shale. The shale is exposed for 3 months or longer and then studied with micro CT scans (and other microscopy methods). This makes it possible to see if there are any changes in their mineralogy. Linked with this project is the National Geosequestration Laboratory, which gathers data from a test well 2 hours south of Perth close to Harvey, known as the Collie-South West CO2 Geosequestration Hub. Curtin’s hope is to turn the Collie-SW Hub into an industrial geosequestration site in a number of years provided that tests of the reservoir and its seal prove it is a suitable site for long-term, industrial CO2 storage.

School of Mining and Petroleum Engineering, University of Alberta, Canada

Strong support of industry and government funding for petroleum engineering research in the School of Mining and Petroleum Engineering at the University of Alberta enables researchers to work on real-world, diverse problems faced by the oil and gas industry. These problems include oil recovery from tight and shale environments by nonaqueous methods such as electromagnetic heating, thermodynamics, and multiphase behavior as applied to numerical modeling of thermal oil recovery; mature field development; formulating improved data-driven modeling approaches based on artificial intelligence and fuzzy logic for the design and optimization of thermal recovery processes; and use of nanometal particles in steam and solvent heavy oil recovery.

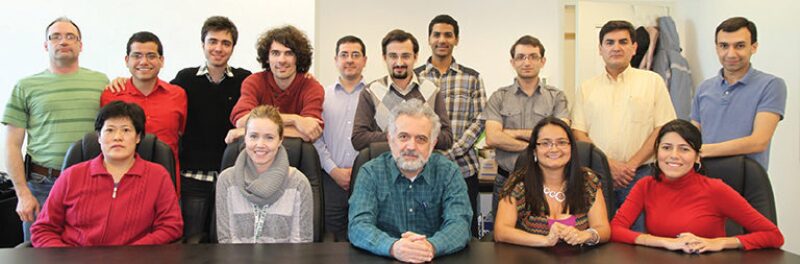

Tayfun Babadagli, professor of petroleum engineering and industrial research chair in unconventional oil recovery at the Natural Sciences and Engineering Research Council, is leading the Enhanced Oil and Gas Recovery and Reservoir Characterization research group to develop ecologically viable technologies for extracting or tapping unconventional oil reserves and resources (Fig. 8). Although Alberta’s oil sands contain an estimated 1.84 trillion bbls of crude bitumen, only about 9% (168.7 billion bbls) is recoverable using current technology. While proven technologies are successfully applied in surface extraction of mined oil sands, in-situ recovery of heavy oil and bitumen is still a considerable challenge due to the technological and economic problems. Through the development of advanced and optimal in-situ recovery techniques under this research program, the potential to recover the remaining reserves is within reach.

The program is designed to deal directly and extensively with ways to improve the efficiency of the depletion of heavy oil and bitumen from sands and carbonates by proposing and testing new methods and materials that do not exist in Canada. The research program has gained industry support from Schlumberger, Canadian Natural Resources, Suncor Energy, Statoil, Husky, Petrobank Energy and Resources, Sherritt International, Apex Engineering, and Pemex.

The program is twofold. First, it focuses on improving existing technologies through experimental and computational modeling and visualization. Fundamental and applied research is conducted to understand the underlying mechanisms and physics of heavy oil and bitumen recovery processes, namely, thermal and solvent injection techniques. This leads to identifying the reasons for low recovery and inefficiency of these applications, including advanced techniques such as microscale (e.g., pore) to gigascale (e.g., field) experimental and numerical modeling studies. Second, the program tests new materials, tools, and techniques to improve the efficiency of the thermal and solvent processes with a focus on fluids/materials that respond electrostrictively and magnetostrictively, and react to changes in temperature or pressure. Under the research program, new techniques also include nonclassical modeling approaches such as random walk, particle tracking, and other types of pore or larger scale stochastic techniques.

The school also collaborates with German scientists through the Helmholtz-Alberta Initiative program. This project aims to assess the feasibility of obtaining geothermal energy for oil sands extraction and processing in the Fort McMurray area of Alberta. A hot dry rock system in granitic basement rock needs to be developed by hydraulic fracturing at a depth of 4000 m to 5000 m and injecting cold water to generate 60°C hot water for oil sands extraction for a period of a few decades at the rate of 50 L/sec. This research involves understanding fracture development in granitic rocks and optimizing the depth and injection rate to minimize cost while maintaining a given production temperature and hot water rate.

Petroleum and Natural Gas Engineering Department, Middle East Technical University, Turkey

The Middle East Technical University created the Petroleum and Natural Gas Engineering Department in 1964. The department has six full-time and eight part-time faculty members as well as 10 research assistants. Four laboratories are available for training and research: Core Analysis and Sample Preparation Laboratory, Pressure/Volume/Temperature Laboratory, Drilling Fluid Testing Laboratory, and Enhanced Oil Recovery Laboratory. The department’s research interests include

- Drilling fluids models

- The environmental effects of drilling and production activities

- Reservoir characterization using CT scans

- Underground storage of natural gas

- CO2 storage

- Natural gas hydrates

While natural gas hydrates and CO2 storage have been studied independently for a long time, the department combined these two topics in one research project that focuses on the interaction between methane hydrates and CO2. The project aims to replace methane trapped in hydrate cages with injected CO2 to produce methane without affecting the stability of the hydrate structure. Other suggested methane hydrate production techniques are based mainly on the dissociation of hydrates by reducing the pressure or increasing the temperature; however, these techniques add the risk of uncontrolled dissociation, which could lead to instability in the hydrate-bearing sediment.

Deep sea sediments have suitable conditions for the formation of hydrates. The Black Sea is one of the major identified natural methane hydrate regions of the world and may be a good candidate for CO2 storage in hydrate form. To determine the interaction of CO2 and methane hydrates and the sealing efficiency of methane hydrates, the department performed various tests including methane hydrate formation in both bulk conditions and within sand particles. A geological structure must contain an impermeable barrier to store huge amounts of CO2. Because of this, the department studied the sealing efficiency of methane hydrates and the long-term fate of the CO2 disposal under the methane hydrate zone by measuring the permeability of unconsolidated sand particles for several values of methane hydrate saturation and by injecting CO2 into the methane hydrates. The results suggest that the presence of hydrates sharply decreases the permeability of the unconsolidated sand system, while hydrate saturations greater than 50% may act as an impermeable layer.