Extreme downhole conditions pose a challenge to formation testing. Acquisition of accurate reservoir pressure data and high-quality formation fluid samples has proved difficult in cases of low reservoir permeability, extremely viscous crude oil, or unconsolidated formations with poor borehole conditions. Operators have often considered these wells untestable. When testing is possible, it is frequently time consuming and costly with the need to set and cement pipe, shoot perforations, and bring in coiled tubing to run the test. Even then, formation pressure estimates on such wells are frequently inaccurate.

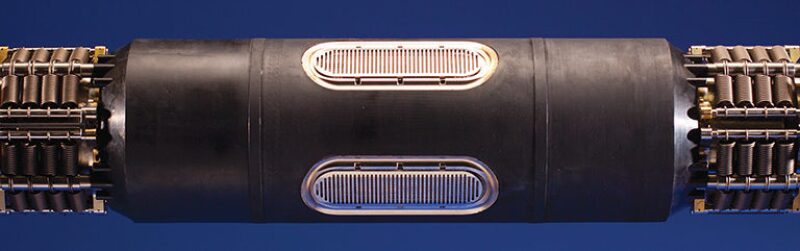

However, a new tool has proved able to extend formation testing parameters to extreme formation and borehole conditions. The Saturn 3D radial probe (Fig. 1) developed by Schlumberger is a complementary module to the Modular Formation Dynamics Tester tool. The probe is capable of performing accurate pressure tests in fluid mobilities as low as 0.01 md/cp, and obtaining high-quality fluid samples in mobilities lower than 1 md/cp.

In Mexico, a friable sandstone reservoir containing 7.5 °API crude oil in extremely unconsolidated formations was successfully sampled by the 3D radial tool in a very rugose borehole with 12% ovality. The data collected would have been unobtainable with previous test assemblies and was critical for a subsequent thermal recovery design. Despite the difficult conditions, the new tool was able to conform to borehole irregularities to achieve and maintain a reliable hydraulic seal.

Formation Fluid Challenges

Acquiring representative samples of heavy, viscous crude is only part of the story. A North Sea operator took full advantage of downhole fluid analysis (DFA) to characterize viscous, biodegraded oil in a poorly consolidated field. The Catcher area fields, operated by Premier Oil on behalf of colicensees Cairn Energy and Wintershall, contain 300 million bbl of original oil in place, making them one of the most significant recent discoveries in the United Kingdom Continental Shelf. Six wells and three sidetrack boreholes have been drilled to date.

The fields are partly characterized by a series of sand injectites, overpressurized sediments that are remobilized and forced upward to intrude into overlying layers. Injected sands are typically characterized by high porosity and high permeability, which is why they are often considered as attractive hydrocarbon targets. However, injectites often range from poorly cemented to unconsolidated, which makes attempts to sample high-quality fluid very challenging.

The fluids that characterize the Catcher fields underwent trap-spilling migration and methanogenic biodegradation, which have resulted in vertical and horizontal fluid variations between the fields. The resulting factor affects oil composition and viscosity. With the complex geometries of the injectite system, the ability to understand the variation of fluid properties can lead to an improved knowledge of the 3D connectivity of the reservoirs.

To be able to maximize recovery, the Catcher license group needed to analyze the crude oil in situ. The group chose to use wireline formation testing with the 3D radial probe and the Schlumberger InSitu Fluid Analyzer (IFA) system for DFA. The analyzer is able to assess the presence of flow assurance impediments, such as asphaltene, scale, hydrates, and paraffin. Many of these appear when formation or flowline pressure declines past a threshold that is determined by their composition. The ability to perform compositional analyses of formation fluid in situ results in a clear assessment of one of the Catcher group’s major concerns—reservoir connectivity.

However, the use of traditional wireline test analysis equipment is limited by factors such as formation fluid viscosity and mobility, and the ability to obtain and maintain a hydraulic seal. In addition, the time needed to obtain a representative sample of uncontaminated formation fluid can add significantly to operating costs.

Improved Technology Pairing

The Catcher group used traditional formation testing equipment and predecessors of the IFA system to acquire and analyze well samples obtained before this year. The data collected in the wells was analyzed using the Flory-Huggins-Zuo (FHZ) equation of state (EoS) program to better understand the vertical and horizontal fluid variations and confirm the previous understanding of the fluid continuities and discontinuities between fields.

Beginning this year, the group has used the 3D radial probe module in combination with the latest IFA tools to maximize the quality of data obtained from wells tested in the Catcher area’s Bonneville field.

The 3D radial probe module is fully compatible with the Modular Formation Dynamics Tester tool and significantly extends the tool’s operating limits in testing low-permeability areas, unconsolidated formations with rugose boreholes, and highly viscous crudes. The 3D radial probe features four orthogonally positioned large area probes spaced around an inflatable packer element that conforms to irregular borehole profiles. Each of the four elliptical probes has almost 20 in.2 of surface flow area. Together, they provide a surface flow area of 79.44 in.2

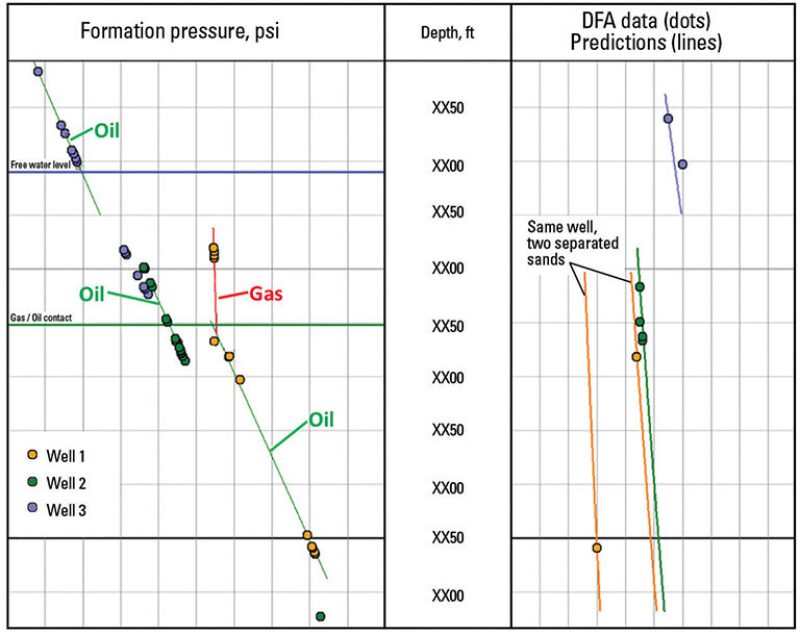

Besides improving the range of fluid sampling in tight formations or in heavy oil areas, the 3D radial probe facilitates the determination of fluid gradients and anisotropy and the measurement of far-field permeability (Fig. 2). Data collected by the tool benefits subsequent well test design. Interval pressure transient testing with reduced storage effect for flow regime identification is also possible.

Solving the Fluid Puzzle

The variations in biodegradation and asphaltene content in the Catcher area fields result in varied fluid distribution and viscosity across the different fields. Asphaltene variations determined by the IFA can be analyzed using the FHZ EoS program to enable the prediction of equilibrium gradients. Specifically, measurements in six wells and one sidetrack borehole yielded 250 pressure levels and several different oil and water gradients. Multiple models are required to describe and predict fluid variations, with depth confirming the predicted continuities and discontinuities within and between fields.

Several factors became apparent from initial analyses. Biodegradation of the oil seems to occur in accordance with migration of the oil across the sand systems. There are variations in viscosity and asphaltene content. These variations were identified initially by the DFA and most recently by the IFA, and were seen as compatible with the migration paths modeled by the Catcher group.

The DFA/IFA analyses were used on the Bonneville wells to provide a real-time indication of reservoir connectivity. Beforehand, a prediction of fluid coloration was made. When real coloration was compared with predicted coloration, matching samples were deemed to come from dynamically connected reservoirs. While pressure measurements can indicate hydraulic connectivity, combining them with the fluid coloration gives a much more reliable indication of the dynamic connectivity.

The major benefit of using the 3D radial probe was its speed in obtaining uncontaminated samples for real-time analysis by the DFA/IFA. Although traditional testers used previously were equipped with a focused sampling probe in which focused extraction of pure reservoir fluid can be separated from contaminants in the flow stream, the high viscosity of the fluid in the formation, combined with the unconsolidated sands, caused unacceptable time delays in the cleanup process.

Typically test times ranged from 5 to 11 hours per test. The use of the 3D radial probe reduced the cleanup time by 65% to 75% and required a maximum drawdown of 35 psi, compared with a drawdown of more than 500 psi needed for the probe-equipped tool.

The Catcher area fluid testing and analysis project marked the first application of EoS analysis in a multiwell study of fields characterized by variable biodegradation. Sample coloration measured in real time by the DFA/IFA module was used to assess vertical and lateral reservoir connectivity by quantifying the fluid’s asphaltene content.

The use of the 3D radial probe greatly reduced the Catcher group’s test time and the rig time needed for sampling, as well as enabled a higher quality of uncontaminated samples to be obtained for analysis.

Acknowledgment

The authors wish to thank the Catcher group for permission to use its data in this article.