Editor’s note: This is the third in a series of four reports with highlights from the Hydraulic Fracturing Test Site in the Permian Basin. First in the series can be read here and second here.

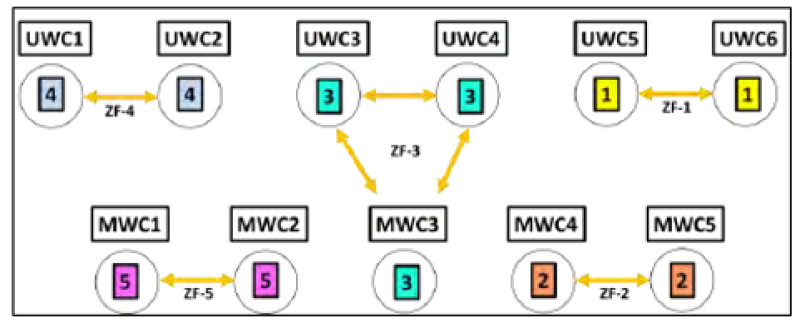

The 11 wells at the Hydraulic Fracturing Test Site were fractured in 2015 using what was then a fairly new method, zipper fracturing. Rather than pumping one well at a time, wells were fractured them in groups—four pairs, plus three wells together in the middle of the pattern.

Zipper fracturing speeds work by allowing continuous pumping and it reduces the risk of frac hits because the method only fractures rock where pressure has not been depleted by production. Now zipper fracturing is used to fracture even more wells at once.

What researchers found at the fracturing test site was that zipper fractures create strong connections. By tracking the pressure responses in nearby wells during fracturing, and the chemical tracers in the fluids pumped during fracturing, they measured the higher degree of connection among those wells.

While fluids injected during fracturing were later observed at other wells on the pad, the ones that were zipper fractured showed more communication, said Ashish Kumar, a graduate research assistant in petroleum engineering at the University of Texas at Austin, who presented a paper on tracer and pressure data analysis at the recent Unconventional Resources Technology Conference (URTeC 2901827).

Connections matter because they can provide a pathway for well interference, when open. The strongest connections were wells where proppant tracers traveled from well to well, suggesting the passageway has been propped open. The paper said that “proppant exchange is very likely to happen between zipper fractured wells.”

Simultaneous fracturing is likely to create stronger connections because the time between stages is relatively short, allowing fluid pumped in one stage to stimulate “induced un-propped fractures that have not closed over this short time” from the previous stage, he said.

Most of the well pairs were on the same bench, spaced 660 ft apart. The five lower wells were 325 ft deeper and spaced in between the six upper wells.

Fractures connected end-to-end can run 1,000 ft or more, but they generally do not have a lasting impact unless the pathway was propped—radioactive tracer tests showed some propped connections among well pairs.

Connected fractures without proppant closed after production began, as did all connections between the middle and upper Wolfcamp. Pumping more sand increased the probability of interaction among multiple wells.

A related study by Core Laboratories found that the same fracturing treatment performed differently in different benches. “Interwell communication within the middle Wolfcamp wells was significantly higher than communication within the upper Wolfcamp wells,” according to a technical paper by the company (URTeC 2902960).

It also reported on a high percentage of proppant had traveled into the reservoir. The proppant was treated to give off a low-level radioactive signal, and the paper concluded more than 90% of the clusters were treated. The signal was detected using a gamma ray log whose range is limited to an area within a couple feet of the wellbore.

The paper also reported that proppant injected at clusters 50 ft apart were as effective as those spaced 90 ft apart, and the wider spacing left more rock unstimulated. This did not vary between wells in the upper and middle Wolfcamp.

URTeC 2901827 Well Interference Diagnosis Through Integrated Analysis of Tracer and Pressure Interference Tests by Ashish Kumar, Puneet Seth, Kaustubh Shrivastava, et al, The University of Texas at Austin.

URTeC 2902960 Interwell Communication Study of UWC and MWC Wells in the HFTS by Tanner Wood, Richard Leonard, Chad Senters, et al, ProTechnics Division of Core Laboratories