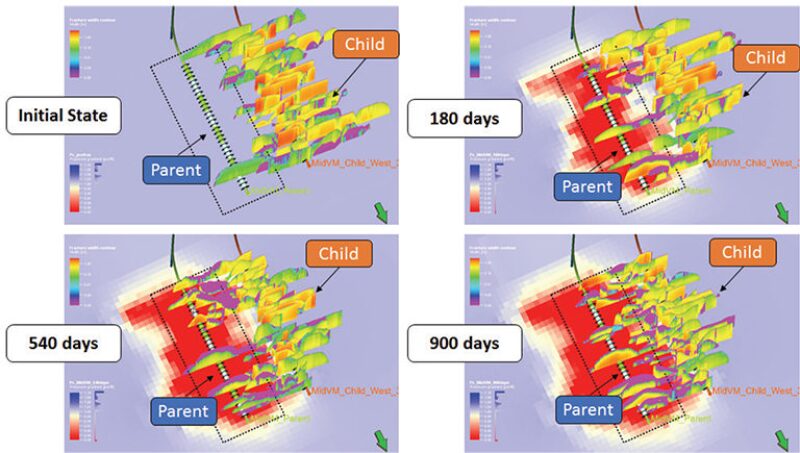

Development of organic shale reservoirs with large hydraulic-fracture treatments not only poses challenges to the completion of a single well, but also to interference with surrounding wells. A direct consequence of interference is production loss. Therefore, the drilling and completion schedule for field development must be 4D in time and space to account for interaction in between wells. The complete paper describes a physics-based model of interference and a sensitivity study to propose guidelines for well spacing and a drilling timeline for multiple horizontal wells in the Vaca Muerta shale.

Introduction

Effective field development relies on the tradeoff between the capital expenditure (CAPEX) and the production profile generating cash flow.

×

Continue Reading with SPE Membership

SPE Members: Please sign in at the top of the page for access to this member-exclusive content. If you are not a member and you find JPT content valuable, we encourage you to become a part of the SPE member community to gain full access.