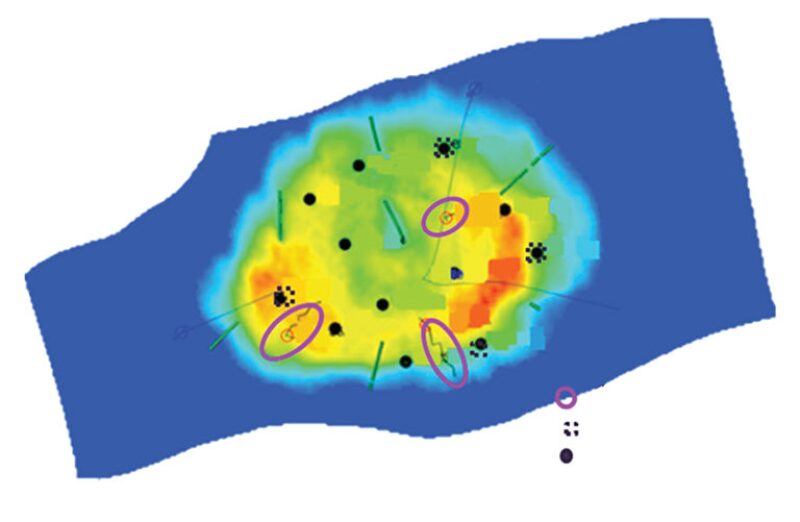

The XamXung field offshore Sarawak, Malaysia, is a 47-year brownfield with thin remaining oil rims that have made field management challenging. The dynamic oil-rim movement has been a key subsurface uncertainty, particularly with the commencing of a redevelopment project. A reservoir, well, and facilities-management (RWFM) plan was implemented to optimize development decisions. This paper is a continuation of paper SPE 174638 and outlines the outcome of the RWFM plan and the results’ effect on development decisions such as infill well placement and gas/water injection-scheme optimization (Fig.

×

Continue Reading with SPE Membership

SPE Members: Please sign in at the top of the page for access to this member-exclusive content. If you are not a member and you find JPT content valuable, we encourage you to become a part of the SPE member community to gain full access.