For the development of the Dvalin high-pressure/high-temperature (HP/HT) gas field in the Norwegian Sea, a completion scheme using standalone screens is planned. To secure maximum cleanup and productivity, even after long-term suspension, comprehensive laboratory testing was performed to evaluate specific properties from drilling and completion fluids at downhole conditions. The complete paper details the results of all test phases. With the test methodology, several proposed mud-system candidates were disqualified at an early stage, thus saving time and cost for subsequent formation-damage testing and complementary analytics.

Introduction

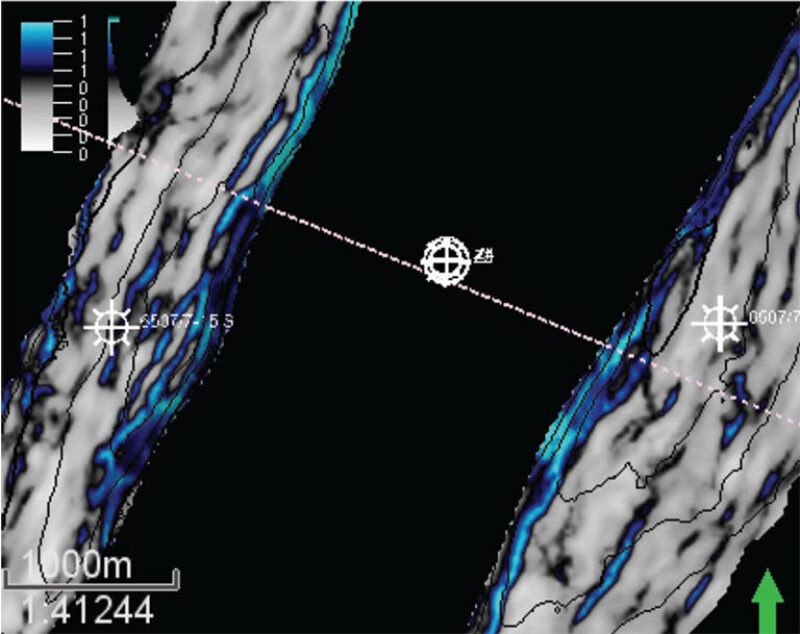

Formation damage is believed to have caused difficulties in modular-dynamic-tester sampling in the high-permeability zone of Dvalin West.