Optimizing resources and pushing drilling limits to tap into deeper reservoirs at minimal cost is a primary objective of operators worldwide. The complete paper describes an offshore artificial island project northwest of Abu Dhabi in which drilling limits were extended continually by adopting new technologies and practices in an extended-reach-drilling (ERD) campaign. The project drilled longer wells at lower cost. The approach has resulted in drilling and completion of wells comfortably within the equipment-rating envelope and is considered a benchmark for nearby fields in the region.

Field Background

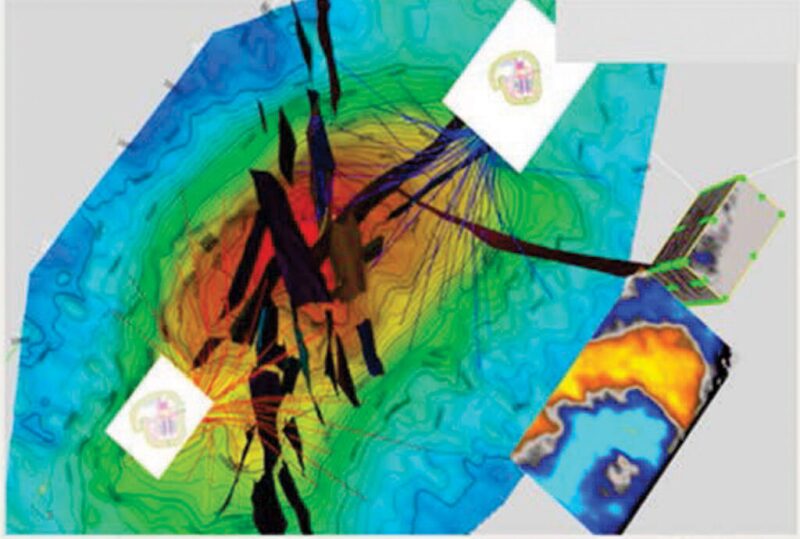

The offshore field is northwest of Abu Dhabi.

×

Continue Reading with SPE Membership

SPE Members: Please sign in at the top of the page for access to this member-exclusive content. If you are not a member and you find JPT content valuable, we encourage you to become a part of the SPE member community to gain full access.