In the midst of an industry downturn last year, the Abu Dhabi National Oil Company (ADNOC) reached a new oil production ceiling of 4 million B/D. The UAE’s largest producer has no intentions of slowing down.

By decade’s end, ADNOC expects to have raised its maximum daily output by another million barrels.

To cross that milestone, the company has set its sights on mastering the tight, thin, and unconventional formations that dot the UAE’s subsurface landscape.

One of the places where such developments are hoped to unfold soon is known as Field Q.

Found in southeastern Abu Dhabi, Field Q sits above a tight carbonate reservoir that holds an estimated 600 million bbl of oil. But with a permeability ranging from 1 to 3 millidarcy and poor vertical communication, the reservoir and its barrels have proven difficult to cultivate economically—until recently.

ADNOC has published new details of its first onshore pilot of a “fishbone stimulation” that involved using more than a hundred hollow needles to pierce as far as 40 ft into the reservoir rock. The additional drainage netted by the fishbone needles boosted production threefold in the test well, as compared with its traditionally completed neighbors on the same pad.

ADNOC ran the pilot in the summer of 2019 and by the end of the year saw enough production data to launch a wider 10-well pilot that remains underway. Based on a longer-term data set from these wells, the company will decide whether to leap into a fieldwide deployment of the niche completions technology.

In the meantime, the petrotechnical team in charge of the test projects have issued roundly positive reviews of the fishbone technique in two recently presented technical papers (SPE 202636; SPE 203086) from the Abu Dhabi International Petroleum Exhibition & Conference (ADIPEC).

“There is a chance that the fishbone- stimulated wells can avoid the drilling of multiple wells targeting different sublayers in the same zone,” said Rama Rao Rachapudi, listing one of several of the technology’s advantages over other approaches that were considered.

The senior petroleum engineer with ADNOC, who is one of several authors of the papers that cover both the drilling and completions aspects of the pilot, shared during ADIPEC that his onshore team found motivation to test the technology after bringing in a batch of dismal appraisal wells.

The fishbone system, also known as multilateral jetting stimulation technology, has been a specialized application ever since it was introduced just over a decade ago.

Underscoring the potential impact of the current round of pilots on the technology’s adoption rate, ADNOC noted there were only around 30 worldwide fishbone deployments prior to this project. Most of those have been in the Middle East’s naturally fractured and layered carbonate formations—just like those of Field Q.

Drilled in 2014 and onwards, the first wells in Field Q averaged production rates of 400 to 500 B/D. These volumes not only fell about halfway short of expectations, but generated wellhead pressures so low that takeaway would become an issue as the development expanded further away from its central facility.

All of these initial wells were completed with acid jobs via coiled tubing units—the bread and butter of conventional carbonate completions in the Middle East. “However, productivity improvement with conventional acid stimulation is very limited and short lived,” in tight carbonates, explained the completions-focused paper.

ADNOC’s first onshore fishbone pilot appears to be a study in contrast.

The test well yielded an initial production rate of 1,600 BOPD with backpressures of 500 to 600 psi, enough to ease concerns over moving the product across the field. In terms of costs, the difference between the appraisal wells and the pilot well was only about $1.3 million.

Touching More Reservoir

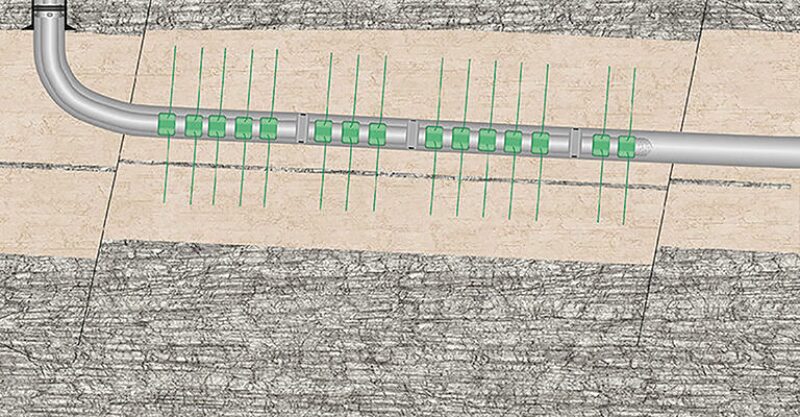

Developed by Stavanger-based Fishbones as part of a joint venture with Equinor and others, the firm’s core product by the same name is comprised of an openhole liner with subunits at fixed intervals. Hiding inside these subs are up to four high-strength needles that when extended from a lateral wellbore resemble something like a fish skeleton, hence the name.

In the ADNOC pilot, 40 subs were run using the drilling rig, accounting for a total of 160 needles. Once the system was run and with the rig still in place, an acid-jetting treatment run through the needles was used to both etch away rock and propel them forward at a 90° angle from the wellbore.

A cutting device called the “needle basket” was used to remove the unused segments of each needle to create access between the tubular needles and the wellbore. The basket run also enables the operator to measure the needles’ effectiveness.

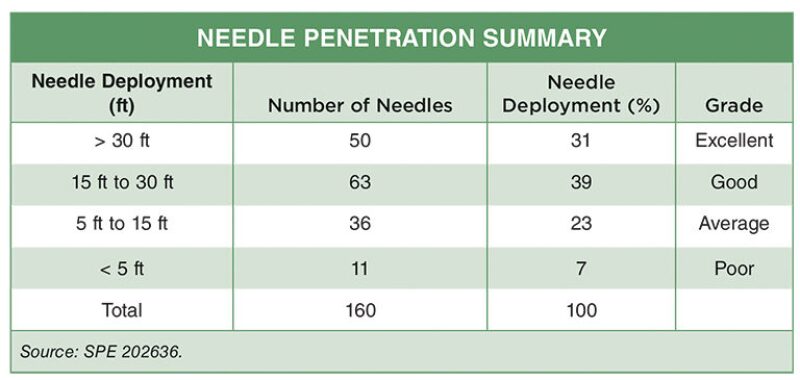

In this case, 70% of the needles penetrated more than 15 ft into the reservoir while only 7% failed to make it past 5 ft. “Based on the actual lengths penetrated into the formation, the reservoir contact was maximized by 3,200 ft,” Rachapudi said.

He added during his presentation that the coiled-tubing completed wells each cost around $7.5 million compared with the $8.8 million for the fishbone well. The additional costs included the specialized completions technology along with extra acidizing fluids and a few extra rig days.

More Control Than Hydraulic Fracturing

Before choosing a production-enhancing technology to test in Field Q, ADNOC’s onshore team looked to a fishbone pilot completed by their offshore counterparts a few years prior. That offshore field trial proved that traditional long laterals were more competitive, however, the lessons learned still indicated that the fishbone completion might be the right application for Field Q.

During the selection process, the onshore team also considered using hydraulic fracturing—but that would have meant ceding a greater degree of control since the process can easily result in unwanted fracture growth.

The risk faced at Field Q, where the target formation is only around 90 ft thick, involved propagating fractures into water-and-gas zones. The fixed length of the fishbone needles significantly reduces such risk.

ADNOC relied on this constraint to avoid the water zones in particular while successfully tapping into those sublayers mentioned earlier. This was a critical objective for the pilot team since it was determined that future wells in Field Q had to have better vertical communication to reach production targets.

In the end, ADNOC concluded that it successfully connected seven of these thin payzones to the test wellbore, which has shown a reduced drawdown effect as compared with the baseline wells. The drawdown improvement was attributed to not only the added reservoir contact but also to having access to the otherwise isolated sublayers which held higher reservoir pressures.

Other advantages of the fishbone stimulation ADNOC listed include the ability of the needles to intersect with producing natural fractures and the circumvention of skin damage that may impede reservoir flow into the wellbore.

For Further Reading

SPE 202636 Fishbone Stimulation a Game Changer for Tight Carbonate Productivity Enhancement, Case Study of First Successful Implementation at ADNOC Onshore Fields by Rama Rao Rachapudi, ADNOC Onshore et al.

SPE 203086 First Successful Fishbone Stimulation Completion in Onshore Oil Field in the United Arab Emirates by Fernando Quintero, ADNOC Onshore et al.