The American Petroleum Institute estimates that oil and gas exploration and production in the US generates approximately 20 billion bbl of produced water annually. And, because the production life of wells is usually advanced, the ratio of barrels of produced water to hydrocarbons recovered can be as high as 9:1.

Accordingly, in the past several decades, produced water has become the largest byproduct in the oil and gas industry. Managing all this produced water includes injecting the water into the formation to maintain formation pressure, thereby increasing hydrocarbon production, or disposing of the water in deep wells. Before the water can be injected, disposed of, or discharged offshore, it is necessary to remove oil, suspended solids, or both to protect formation rheology or to meet discharge regulations.

If you ask an experienced produced water process engineer working in the oil and gas industry—they are getting harder to find these days—how to treat produced water, be prepared to answer a lot of questions. And, these are likely to be on a range of topics such as local operating conditions, characteristics of the produced water, water treatment requirements, and available treating options. It is also important to understand that produced water contains chemical characteristics of the formation and its associated hydrocarbons. Plus, the properties of produced water and its volume vary considerably depending on the location of the field, its geologic formation, the type of hydrocarbon product being produced, and the reservoir’s age.

For those new to produced water, the preceding information can be overwhelming. But for produced water experts, it is the basis for developing an effective and efficient produced water treatment strategy.

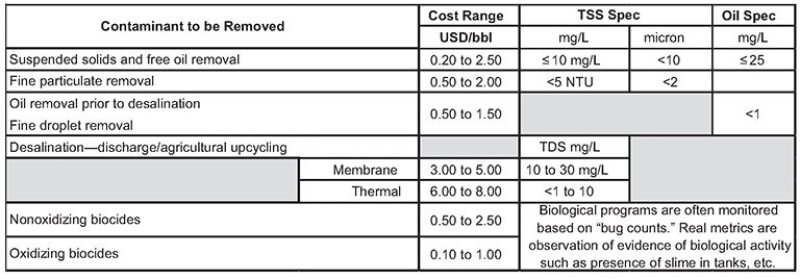

While an initial analysis could begin with a number of variables, contaminants in the water and the water quality requirements determine the treatment process. Contaminants are generally categorized into three types: suspended oil droplets/particles, dissolved organics and inorganics, and biological matter.

Free Oil and Suspended Solids

Free oil and suspended solids represent the most common challenges to treating produced water. For offshore discharge, oil removal is necessary to meet local regulations. When water is injected, both onshore and offshore, the particulate threatens the formation rheology, well productivity, and well life. Left to separate from the water naturally, the process could take years, making the method impractical.

The rate of separation of free oil and suspended solids from produced water can be accelerated using the following methods:

- Increasing oil droplet/solid particle size

- Changing water flow direction

- Decreasing water flow velocity

- Decreasing oil droplet/particle density

Increasing the size of droplets/particles is effected through charge neutralization by adding cations such as iron or aluminum. Once neutralized, the oil droplets/particles collide and stick together in what is termed the agglomeration process. As the particles coalesce and form larger aggregates, their separation speed from the water increases geometrically.

Changing the direction of a produced water stream containing oil droplets, particles, or both causes these entrained contaminants to separate from the water. By using coalescing media, a stream of produced water can be forced to change direction multiple times. This process can separate the heavier particles and the lighter oil droplets from the water. The resulting high coalescence of droplets and particles increases the collision rate, causing agglomeration.

Decreasing the velocity of a produced water stream promotes the separation of solids and oil. The rate and efficiency at which this process occurs is dependent on the droplet/particle size, density, and the velocity of water.

Decreasing the density of oil droplets/particles can be accomplished by attaching them to gas bubbles. Decreasing their densities to a point that is substantially lower than the produced water in which they are suspended allows the particles to rise and separate. It can be done by injecting gas, producing bubbles that range in size from 100 and 200 microns, or by causing a pressure drop that releases dissolved gas bubbles as small as 10 to 20 microns. The oil droplets/particles entrained in the water will attach to gas bubbles or be drawn up by the bubbles’ lift and rise to the water’s surface where they can be removed with a skimming or overflow device.

Dissolved Organics and Inorganics

Dissolved organics and inorganics include hydrocarbons such as aromatics, and inorganic salts such as calcium carbonate. These contaminants must be removed for discharging into the environment or upcycling into agricultural or upstream applications, such as steam-assisted gravity drainage. Dissolved organic contaminants can be removed from produced water by destabilization and precipitation prior to fine particulate removal.

Desalination is the process by which inorganic salts are removed. Desalination process technologies are generally categorized into two types: thermal and membrane. For produced water with total dissolved solids ≥40,000 mg/L, thermal desalination technologies, including multistage evaporators and vapor recompression, are used. For produced water with total dissolved solids ≤40,000 mg/L, membrane systems are used.

Biological Matter

Biological matter includes bacteria and all their metabolic byproducts. Bacteria develop in produced water as a result of contamination during exploration and production. Bacteria and their metabolic activity can cause equipment fouling and failure as well as reservoir damage. Control of the microbiological community in a water system can be sustained through “good housekeeping,” which can substantially reduce the use and expense of biocides that must also be applied.

Summary

The fundamental principles covering the treatment of produced water are becoming increasingly important in the production of hydrocarbon resources. Understanding how produced water contaminants and water quality determine mechanical and chemical treatment options, along with capital and operating costs, is essential. Removing contaminants is crucial to maintaining well productivity, well life, equipment integrity, and sustaining environmental compliance. Expert water process engineers provide a core competency in the development of an effective produced water management program that optimizes costs and water quality.