The first full-scale prototype of a subsea variable speed drive (VSD) was tested last month in a sheltered harbor in Vaasa, Finland. Designed for subsea gas compression, the subsea VSD operated over 3 weeks in a back-to-back configuration directly with the grid, without motor loads.

|

A 5-year joint industry project (JIP), started in 2013 between Chevron, Total, Statoil, and ABB, aims to develop transmission, distribution, and power conversion systems for subsea pumps and gas compressors operating at depths of 3000 m and over long distances.

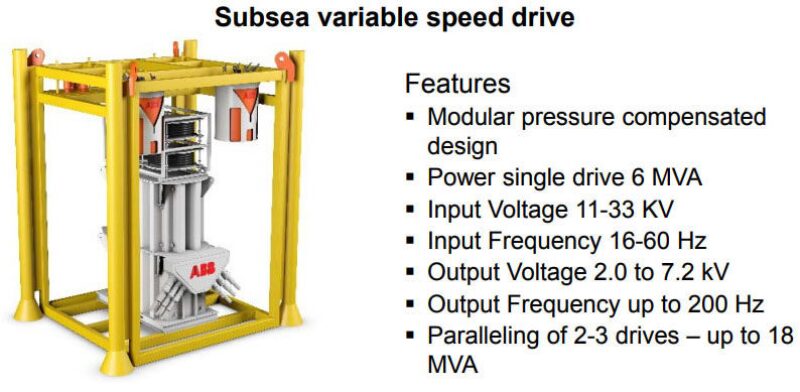

The VSD uses a pressure-compensated design, whereby its power components are cooled by being submerged in oil. The water test proved that the electronic and power components can meet the thermal performance demanded. Before the test, the main drive sub-assemblies and components were pressure-tested at 300 bars in Statoil’s R&D facility in Trondheim, Norway.

Bazmi Husain, ABB CTO, said, “We have demonstrated the successful and reliable operation in a number of high-stress conditions. This is a major milestone in solving such a grand challenge. It takes technology from the laboratory to the field in a structured qualification and pragmatic process, via prototypes and multiple demonstrations.”

The goal is to take power distribution from onshore to the seabed with up to 100 MW capacity being transmitted 600 km to free up the limited space on topside installations. Reduction in costs is possible by having one cable that is distributed to many subsea loads. Additionally, operational costs are reduced, energy and CO2 emissions are lowered, while marine pollution is cut and decommissioning is simplified.

We have to prove to our customers that the entire installation is going to be ultra-reliable because pulling up equipment from 3000 m costs a lot of money,” said Per Erik Holsten, managing director of ABB’s Oil, Gas, and Chemicals business.

The next step is the 3,000-hour shallow-water testing of a subsea power system with two VSDs in a parallel, combined with subsea switchgear and controls, targeted to start late 2018. The first installation of the new subsea power systems in offshore production sites are expected in 2020.

For Further Reading

OTC 27684 Subsea Power JIP—As Enabler for All-Electric Subsea Production by J.Ø Bugge and S. Ingebrigtsen, ABB.