An onshore gas-processing facility in Southeast Asia currently receives rich wet gas from an offshore production unit. Because of an inefficient scrubber design, the gas-processing facility was experiencing natural-gas-liquid (NGL) carryover of 1,550 B/D from the scrubber into the pipelines. A retrofit scrubber was designed to increase the NGL production by 8,540 B/D. This paper presents details of the retrofit scrubber design and shows the importance of using high-efficiency separation internals.

Challenges With the Existing Scrubber

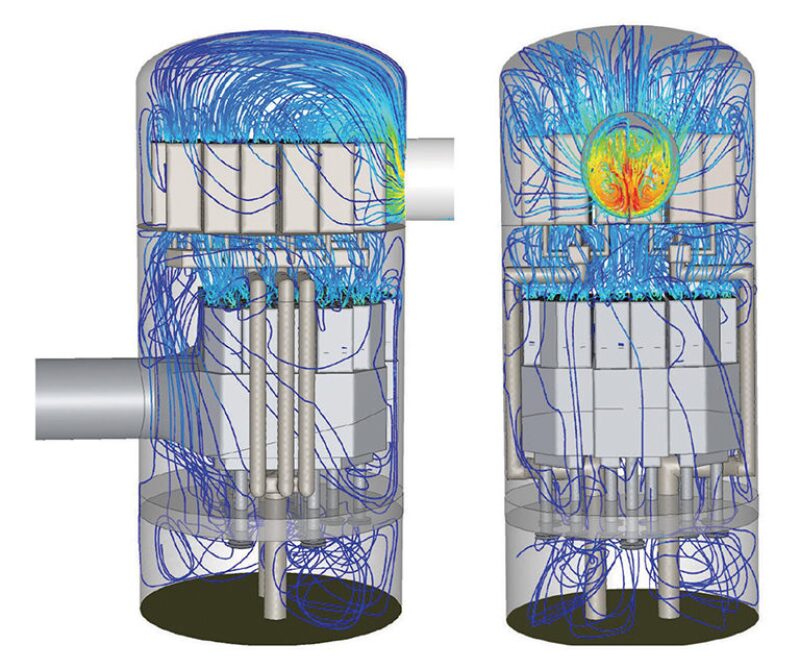

The condensate scrubber vessel was originally designed to handle 300 MMscf/D of gas. The condensate scrubber had an inlet vane and pack internals along with a mesh pad for final demisting.

×

Continue Reading with SPE Membership

SPE Members: Please sign in at the top of the page for access to this member-exclusive content. If you are not a member and you find JPT content valuable, we encourage you to become a part of the SPE member community to gain full access.