Well integrity/control

The authors challenge the traditional planning and execution of interventions, both from an operational and commercial standpoint, and examine where room exists for significant improvement in the industry

This paper provides insights into the technical and economic viability of repurposing oil and gas wells for geothermal energy production for direct heating.

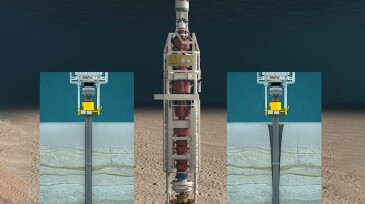

This paper addresses the challenges related to well control and the successful implementation of deep-transient-test operations in an offshore well in Southeast Asia carried out with the help of a dynamic well-control-simulation platform.

-

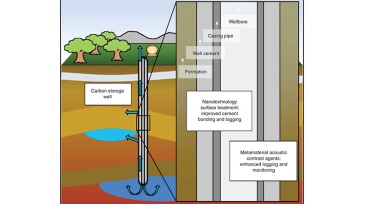

The authors of this paper describe a suite of technologies that enables enhanced well robustness and performance modeling and monitoring of carbon storage facilities.

-

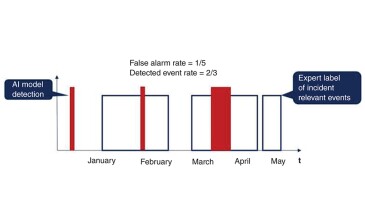

This paper presents the proof of concept of artificial-intelligence-based well-integrity monitoring for gas lift, natural flow, and water-injector wells.

-

This paper defines conditions for optimized well-diagnostics investigation and describes a rigless solutions for common well-barrier failures and lessons learned from operator field trials.

-

Typically, oil and gas producing wells are abandoned toward the end of their life cycles with reservoir pressures depleted compared with the virgin pressures. Carbon capture and storage projects, however, present different operating conditions.

-

SponsoredWith more surface facilities and infrastructure in oil and gas fields, well casing integrity is becoming an even bigger challenge. This article sheds light on the optimum way to deal with the increasing casing integrity challenges in the Middle East through field monitoring and time-lapse casing-integrity and corrosion-inspection logging.

-

Prior to proceeding with a contract to fulfil a rigless P&A campaign for Sasol in Mozambique, BiSN designed a field trial to prove the effectiveness of its bismuth plug technology. Although the technology had been used in 19 countries by BiSN for a variety of downhole applications, it had not yet been qualified for use in Mozambique.

-

Over a 10-year period, sensors monitoring the motion and loads near subsea wellheads have been mounted on more than 300 drilling campaigns. Integrity parameters were calculated to assess whether subsea conductors provided the intended amount of support during drilling operations. In several of these campaigns, loss of conductor support due to integrity issues was obse…

-

This paper describes the material selection methodology and corrosion studies performed in a CO2 sequestration project to optimize well costs and improve overall project economics without jeopardizing the CO2-injector-well integrity.

-

This paper presents an intelligent tube solution that combines data retrieved by the sensors with the actual resistance of each pipe in the well to allow adjustment of production parameters while ensuring installation safety.

-

This paper introduces a method using a Bayesian network to aggregate trends detected in time-series data with events identified by natural language processing to improve the accuracy and robustness of kick and lost-circulation detection.

Page 1 of 11