The shale revolution made water management for hydraulic fracturing a hot topic in the US. Hydraulic fracturing to extract shale oil and gas requires large quantities of water and produces a sizeable amount of flowback. Water sourcing, handling, and disposal represent significant parts of the operating costs in these operations. US shale operators are continually evolving their water management practices to optimize water use and costs.

There are many environmental, sustainability, and legislative issues associated with water handling for hydraulic fracturing. This article provides an overview of some of the main trends and issues related to water management for tight oil and gas.

Introduction

Driven by the development in shale or tight oil, US crude oil production will average 10.6 million B/D in 2018, which would make it the highest-ever annual average production level (Energy Information Administration 2018a). The US Energy Information Administration’s (EIA) recently released Annual Energy Outlook 2018 reference case projects that US tight oil will account for about 65% of cumulative domestic production in the reference case over the projection period of 2017 to 2050 (EIA 2018b).

Over the last decade, advances in multistage hydraulic fracturing and horizontal drilling coupled with the high oil prices at the time led to the US shale revolution. The shale drilling boom and the hydraulic fracturing made water management issues a complex and expensive aspect of these operations.

Hydraulic fracturing is a completion operation in which a hydraulic fluid is pumped down a well under pressure high enough to exceed the formation fraction gradient to create fractures through which oil or gas can flow into the well bore (API 2015b).

Hydraulic Fracture Water Life Cycle

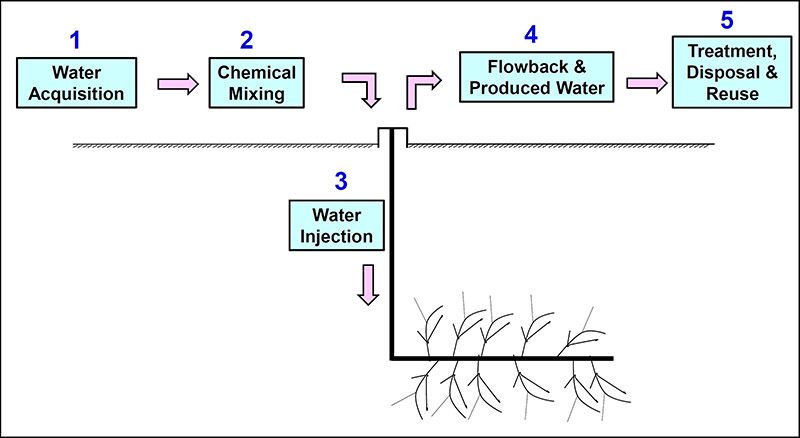

The hydraulic fracturing water life cycle includes the following phases (Dunn-Norman et al. 2018):

- Water acquisition. Sourcing water and transporting it to the wellsite

- Chemical mixing. Adding chemical, additives, and proppants

- Water injecting. Injecting the water under high pressure through the well tubing to the target formation

- Flowback and produced water. Recovering produced fluids from the formation after hydraulic fracture operation.

- Wastewater treatment. Wastewater treatment to meet required specifications for reuse and/or disposal.

Increasing Complexity of Water Management

Dunkel (2017) reviewed the history of water management for unconventional oil and gas. In the early days of shale plays development, water management was normally an afterthought. Typically, water was obtained locally from groundwater or surface resources.

There are several reasons why water management is becoming more complex and expensive for operators.

The dramatic increase in the number of wells drilled puts pressure on available water resources. Furthermore, companies are using more water per well because of longer laterals and more water per foot (Dunkel).

Donaldson (2017) cites two main drivers for the increasing costs and complexity of water management: increasingly expensive freshwater resources and the rising pressure from regulators regarding the disposal of produced fluids.

In recent years, the oil industry had to take into consideration the changing public perception and attitude toward the hydraulic fracturing of wells. Among the key issues: public concerns about truck traffic, potential seismic activities (earthquakes) caused by injection of produced water in disposal wells, and the risks of contaminating drinking water resources.

Hydraulic Fracturing and Drinking Water Resources

One of the main public concerns with hydraulic fracturing is the potential contamination of drinking water resources. The US Environmental Protection Agency (EPA) studied the relationship between hydraulic fracturing for oil and gas and drinking water resources (EPA 2016). The study included a review of published literature, analysis of existing data, scenario evaluation and modeling, laboratory studies, and case studies. The agency released a progress report in December 2012, a final draft assessment report for peer review and comment in June 2015, and the final report in December 2016.

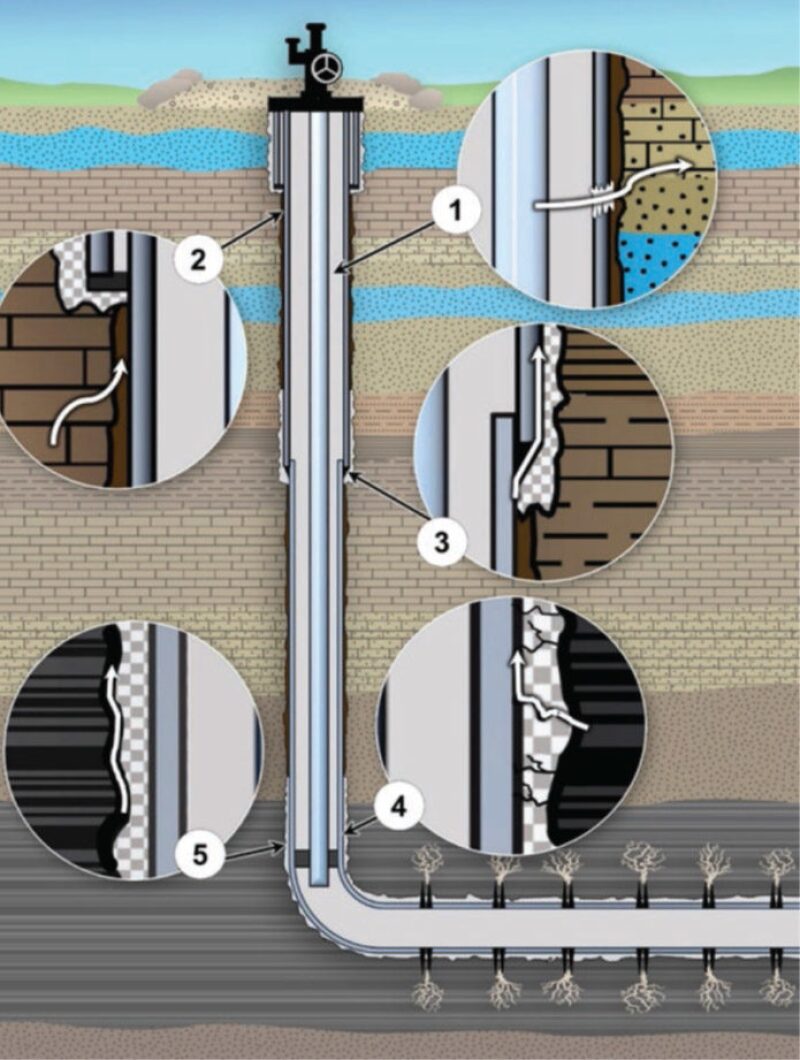

The report addressed the issues associated with each of the five stages of the hydraulic fracturing water life cycle noted above. For risks associated with subsurface contamination, the five major pathways for fluid movement that may potentially allow for fluid movement in a cemented well are shown below.

The EPA report concluded that hydraulic fracturing activities can impact drinking water resources under some circumstances and identifies factors that influence these impacts.

Dunn-Norman et al. provides a comprehensive summary of the EPA study effort and processes. The authors explain the study background, methodology, highlight key findings as well as the limitations of the study.

Impacts of Shale Development in Texas

In addition to work by federal agencies, several studies were conducted on the impact of shale oil production at the individual states. An example of this is the study initiated by TAMEST in the state of Texas. TAMEST is the scientific organization of all Texas-based members of the National Academies of Sciences, Engineering, and Medicine and the state’s Nobel Laureates. It convened a task force to conduct a comprehensive review of scientific research and related findings regarding impacts of shale oil and gas production in Texas (TAMEST 2017).

Shale oil production in Texas is from two major basins, the Permian Basin and Eagle Ford, and it is the leading state in the US in shale oil production. The focus of the task force was on six key areas related to shale exploration and production activities in Texas:

- Geology and earthquake activity

- Land resources

- Air quality

- Water quantity and quality

- Transportation

- Economic and social impacts

The task force report published the report last year, and it was presented at a special panel session at last year’s ATCE in San Antonio, Texas.

The report gives the findings and recommendations with regard to water management issues in Texas. It notes that the depth separation between oil-bearing zones and drinking-water-bearing zones in the state makes direct fracturing into drinking water zones unlikely, and it has not been observed. Surface spills and well casing leaks near the surface are the most likely pathways for oil and gas activities to lead to contamination of drinking water sources and environmental damage.

US Regulations

In the US, there are a number of agencies at the federal and state level that are involved in the regulation and legislation of hydraulic fracturing. Gray et al. (2017) provides a comprehensive assessment of federal, state, and local regulations and legal activities.

Who exactly has the authority to regulate hydraulic fracturing in the US? Gray et al. note that the answer can be a complicated one and a source of friction between the various agencies.

At the federal level, the authors. provide a review of the various US laws that are relevant to hydraulic fracturing including:

- Safe Water Drinking Act

- Energy Policy Act of 2005

- Various resources and conventions acts

They note that the legal landscape is continually changing for hydraulic fracturing and wastewater disposal wells and highlight the importance of reviewing company operating procedures to ensure compliance with current regulations and laws.

API Standards

Throughout the world, API standards are the most widely used standards in the oil industry. Not surprisingly, API standards are the most widely cited standards by US federal and state regulators (Benge et al. 2018).

API published three standards related to hydraulic fracturing. Benge et al. provide an overview of these standards.

- API RP 100-1 (ANSI/API 2015a): addresses well integrity and fracture containment

- API RP 100-1 (ANSI/API 2015b): deals with managing environmental aspects associated with hydraulic fracturing

- API Bulletin 100-3 (ANSI/API 2015): gives guidelines for community engagement

API RP 100-2 in particular addresses water issues and provides recommended practices for water management including water acquisition, transport, storage, use, and disposal. The standard addresses the design and execution of the well plan such that groundwater is isolated and protected during the drilling and subsequent fracture stimulation operations. It also deals with well design and construction to meet the expected fracture load requirements. Operators should consider the full life cycle of water and the project.

As noted in the standards, it is important to consider these recommended practices as early in the project planning as possible. A comprehensive water management plan document should be appropriate for large projects.

Development of Water Infrastructure

Dunkel (2017) notes that over the next several decades water pipelines are expected to spread progressively, driven predominantly by cost reduction and sustainability of water sourcing and disposal. It is possible to envisage water pipeline networks systems in the oil-producing regions of the US, somewhat similar to the existing CO2 pipelines infrastructure used to supply CO2 for enhanced oil recovery applications.

The extent of water reuse varies between the various shale-producing areas in the US. A qualitative summary of the water management issues in the various US shale basins is given by Dunkel and is reproduced below.

Table 1—COMPARISON OF BASIN WATER ISSUES

Basin | Water Sources | Water Disposal | Water Reuse | Trucking |

|---|---|---|---|---|

Bakken | Plentiful | Good | Limited | Frequently |

Eagle Ford | Fair | Good | Limited | Frequently |

Marcellus / Utica | Plentiful | Very Limited | Frequently | Frequently |

Mid-continent | Fair | Limited | Limited | Frequently |

Permian | Fair | Good | Limited | Frequently |

Source: Dunkel 2017.

An example of water infrastructure used in a recent project that involved reuse of produced water is described by Donaldson. It comprises

- Freshwater storage

- A produced water trunkline system

- A gathering and treatment facility for produced water

- Produced water storage and blending tanks

The entire arrangement is strategically located in proximity to several active fracturing locations. Donaldson points out that one of the challenges when reusing water for hydraulic fracturing is the correct mixing or blending ratio in order to obtain the fluid that meets the required project specification.

Whitfield (2018) notes that the trend in the Permian region is for operators to develop permanent infrastructure, instead of relying on temporary solutions such as trucks to haul away the large volumes of produced water. He gives examples of oilfield water management companies in the Permian region acquiring pipeline infrastructure, disposal wells, and facilities.

SPE and Water Management

The importance of water management for tight oil and plays is recognized by SPE and is reflected in the many papers on the subject presented at SPE conferences and the various articles published in SPE online publication Oil and Gas Facilities (OGF) and the Journal of Petroleum Technology (JPT). JPT cover stories were about shale water management in November 2017 and January 2018. Other articles include Jacobs (2016), Donnelly (2017), and Whitfield (2017)

The SPE is currently restructuring the Water Handling & Management Technical Section and redefining its scope. It is envisaged that the scope of the technical section would include water management issues in both conventional and unconventional fields, such as:

- Water sourcing

- Chemicals

- Produced water and flowback water treatment

- Water disposal

- Operations best practice

- Environmental and sustainability issues

- Cooperation with other professional societies

- Industry standards

- US and international regulations

There are over 1,300 SPE members registered in the Water Handling and Management Technical Section. Any SPE member may join a technical section.

For Further Reading

SPE 189873. 2018. A Summary of the US Environmental Protection Agency’s Multiyear Study of the Potential Impacts of Hydraulic Fracturing on Drinking Water Resources by S. Dunn-Norman, W. Hufford, and S.W. Almond.

SPE 189897. 2018. New API Standards for Shale Development by G. Benge, D. Miller, S. Miller, and R. Goodman.

SPE 184445. 2017. Sustainability Aspects of Water Infrastructure by M.R. Dunkel.

SPE 184859. 2017. Current Regulatory Issues Regarding Hydraulic Fracturing by M. Gray, N. Deutsch, and M. Marrero.

Donaldson, B. 2017. Best Water Management Practices in the Permian Basin, World Oil, 238 (11): 47–50.

EIA 2018a, Short Term Energy Outlook, 5 February 2018. https://www.eia.gov/outlooks/steo/

EIA 2018b, Annual Energy Outlook 2018. https://www.eia.gov/outlooks/aeo/

US EPA. 2016. Hydraulic Fracturing for Oil and Gas: Impacts from the Hydraulic Fracturing Water Cycle on Drinking Water Resources in the United States (Final Report). U.S. Environmental Protection Agency, Washington, DC, EPA/600/R-16/236F, 2016.

TAMEST 2017. Environmental and Community Impacts of Shale Development in Texas, The Academy of Medicine, Engineering and Science of Texas, Austin, Texas.

API 2015a. ANSI/API Recommended Practice 100-1. Hydraulic Fracturing & Well Integrity and Fracture Containment, First Edition, Washington DC: American Petroleum Institute.

API 2015b. ANSI/API Recommended Practice 100-2. Managing Environmental Aspects Associated with Exploration and Production Operations Including Hydraulic Fracturing, First Edition, Washington DC: American Petroleum Institute.

API 2014. ANSI/API Bulletin 100-3. Community Engagement Guidelines, First Edition, Washington DC: American Petroleum Institute.

Jacobs, T. 2016. More Oil, More Water: How Produced Water Will Create Big Cost Problems for Shale Operators, J Pet Tech 68 (12): 34–39.

Whitfield, S. 2017. Permian, Bakken Operators Face Produced Water Challenges, J Pet Tech 69 (6): 48–51.

Donnelly, J. 2017. Hydraulic Fracturing Studies, J Pet Tech 69 (7): 12.

Whitfield, S. 2018. Water Demand Spurs Permian Infrastructure Investment, J Pet Tech 70 (1): 26–30.