When I was asked to write for TWA about sand control, I immediately said “Yes, but where should I start? Why would you, a young professional, be interested in sand control and what I would like to say?”

I probably should start from the beginning. I was born in the Soviet Union, Russia, in a family of academicians. It was a very different society; life behind the Iron Curtain. Entering a university and studying science was what everybody expected from me, and the option of joining the oil industry was not in my plans. I was dreaming about devoting my life to work at the Academy of Sciences doing fundamental research and maybe teaching, following the footsteps of my parents. Everything changed in 1991, with the end of the Cold War and the collapse of the Soviet Union. It was a very difficult time: total chaos in the lives and minds of people, loss of jobs, rise of crime, etc. It was also an interesting time as we had an opportunity to start businesses, explore the world, and try to pursue the avenues which were not available for our parents and grandparents.

After I received my PhD degree, I spent a year at Institut Français du Pétrole in France as a post-doctoral fellow and then took the position of a research associate at the University of Calgary in Alberta, Canada. My research was related to the investigation of the interfacial phenomena in reservoir rock. The more I learned about oil-water-rock systems, the more I was fascinated by how what is happening in a reservoir on the micro-level affects the efficiency of oil recovery, the quality of the produced oil, and in the long term, the success or failure of a particular project. I got interested in technology development and after choosing to expand my horizons, I joined Weatherford Laboratories Canada where I got exposure to a variety of projects, learning about sand control and the importance of geoscience in making smart engineering solutions. I got involved with SPE helping to organize different technical conferences, working with students, and presenting technical papers. Both my job with a service company and involvement with SPE made me feel that I belong to something big and exciting, the oil industry, and made me proud. Currently, I am with a manufacturing company, Delta Screens, and my focus is helping companies involved in heavy oil and bitumen production operations with sand control design. It is exciting to be involved in new technology development, being able to use my reservoir knowledge, and keep learning as every day brings something new.

Why Sand Control?

Production of formation sand is one of the oldest problems in oil and gas industry. Sand production is very common for geologically young and shallow formations which have little or no cementation. Formation sand or fines with fluids can be encountered in both clastic and carbonate hydrocarbon deposits. By definition, sand control refers to managing/minimizing sand production during petroleum production. Sand and fine particles produced with oil and gas can cause well plugging, erosion, and wear of production equipment, production downtime, expensive repairs, and potentially loss of containment (serious safety risk). Achieving maximum well productivity without excessive sand production or plugging requires sand control that depends on the type of the reservoir and production technology.

Sand control is used in deep offshore wells, shallow conventional wells, thermal heavy oil production operations, shale projects to prevent hydraulic fracturing sand backflow, water wells, etc.

Sand Control Methods

Sand control can be active and passive. Active sand control is the most common and implies the use of mechanical devices, typically a pipe with different types of slots or a screen; it can be also the use of chemical methods based on sand consolidation. Passive sand control is based on oriented perforation or controlled drawdown. Examples of mechanical sand control devices are shown in Fig. 1.

The Role of Geoscience

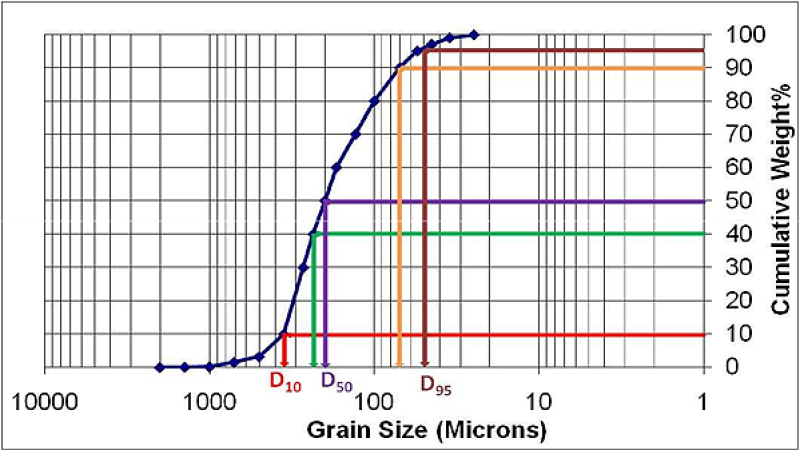

The key for successfully designing sand control is understanding the reservoir, which involves getting representative core samples and core analysis (mineralogy, particle size analysis [PSA], roundness and sphericity, etc.). An example of PSA data is shown below.

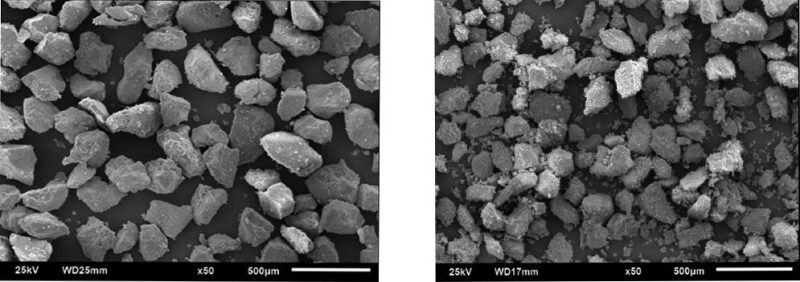

Based on the PSA data, information from the literature and analogue fields, one can typically determine the type of the sand control methods for a particular project. However, having PSA data is often not enough. Heavy oil and bitumen deposits are typically found in unconsolidated sandstone (oil sands) and are in particular prone to sand production issues. Images of a better-quality oil sand and poorer-quality oil sand are shown below. Reservoir minerology, formation water composition, oil viscosity, the effect of production operations, and other factors should to be taken into account to design successful sand control.

Technology development never stops. When it comes to control, the hot topic these days is inflow control devices/flow control devices to control fluid flow in a reservoir, improve sweep efficiency, and total recovery. Due to the recent downturn in the industry, everyone is also focusing on lowering production costs and improving project economics. There is definitely no end to challenges and this is what makes this industry so exciting and rewarding.

Uliana Romanova has more than 20 years of experience in both academia and industry, with the focus on research and technology development in heavy oil and oil sands, in particular sand control, and currently works for Delta Screens. She is a recipient of the Distinguished Service Award of the Canadian Institute of Mining, Metallurgy, and Petroleum and the 2016 Regional Service Award of SPE Canada in formation evaluation. Romanova serves on several SPE technical committees and the board of SPE Canada Educational Foundation.