The Advanced Energy Consortium (AEC) is an internationally recognized research organization dedicated to achieving transformational understanding of subsurface oil and natural gas reservoirs through the deployment of unique micro- and nanosensors (Johnson 2010). The AEC was formed in 2008 by the University of Texas at Austin’s Bureau of Economic Geology and major oil and gas companies to focus on conducting precompetitive research to address challenges in upstream exploration.

Multiple sensor-technologies are being developed by the AEC and investigated in several applications, including wellbore characterization, hydraulic fracturing, waterflooding, enhanced oil recovery (EOR), and interwell reservoir characterization. The vision is exciting as it explores technologies for oilfield rocks in harsh environments, including high temperatures, high pressures, small pore spaces (30 nm to 10 µm), high salinity, and varied pH conditions. Since January 2008, more than USD 45 million has been invested in AEC research projects.

The applications being developed by the AEC have the potential for dual use in other scientific and industrial fields. AEC’s research has developed several novel concepts and solutions that have resulted in more than 40 patent applications and more than 200 publications. This article describes an overview of AEC’s nanotechnology innovations and target applications in the oil and gas industry.

Research Applications

The current portfolio of AEC’s research consists of 21 projects funded at global universities and research institutes. These efforts have been divided into three major research areas: contrast agents, nanomaterial sensors, and microfabricated sensors. In addition, a collection of projects addresses the critical and common needs of the three portfolios to enable transport of nanoparticles deep into the reservoir. Topics include nanoparticle stability (lifetime) and transport (minimizing retention) enabled through coatings and/or custom synthesis.

Contrast Agents for Waterflood and Hydraulic Facture Management

Contrast agents are passive, tracer-like molecules or nanoparticles having augmented electromagnetic, acoustic, or other discernible properties. They are capable of being dispersed in fracturing, wellbore, or waterflood injection fluids to increase the ability of sensing the spatial extent of those fluids by using available imaging techniques.

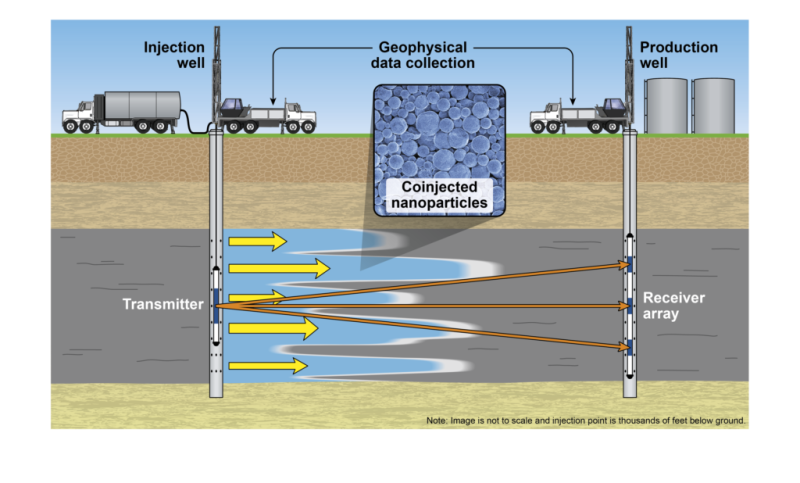

AEC researchers are investigating the use of contrast agents to map the flood front in conventional reservoirs and locate bypassed oil pay zones (Fig. 1). The data gathered through this application will enable intelligent control of injected fluid volumes, rates, and entry and exit points (perforations) for the various injector wells, and result in an improved oil recovery while reducing water processing and drilling cost (Rahmani et al. 2015).

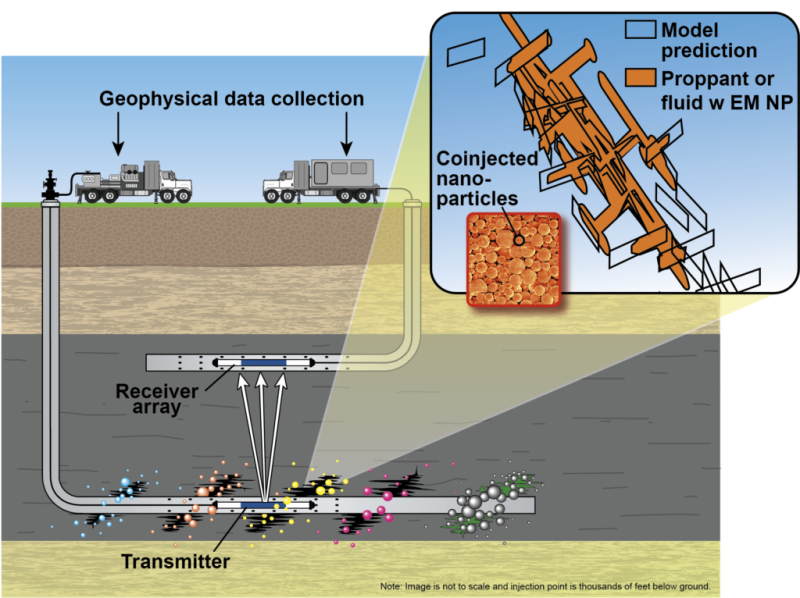

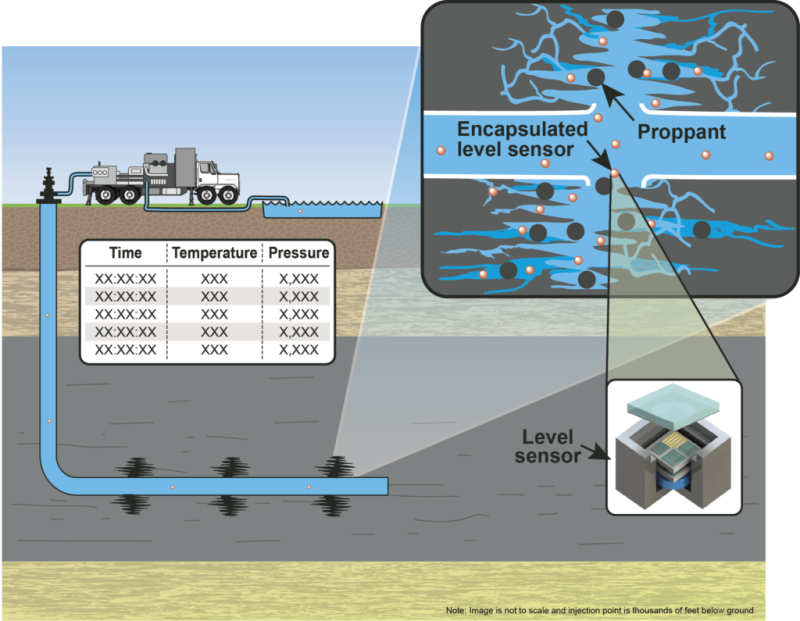

Characterizing hydraulic fractures—fracture height, length, spacing, orientation, and shape—is key to maximizing oil and gas production and ultimate recovery from a hydraulically fractured field. Currently, state-of-the-art fracturing imaging employs microseismic monitoring, which provides general information about rock mechanics but fails to accurately resolve the extent of connected fracture geometry and fluid permeability within the fractured network. AEC is developing an integrated electromagnetic geophysical program to help address the critical gaps in assessing and characterizing the extent of fracture geometries and network permeability for this scenario (Fig. 2).

Contrast agents will be used for identifying the location of proppants, fluids, and hydraulic and natural fractures near the wellbore and in the interwell space with greater accuracy than current technology allows (LaBrecque et al. 2016).

Nanomaterial Sensors for SOR Determination and Waterflood Conformance

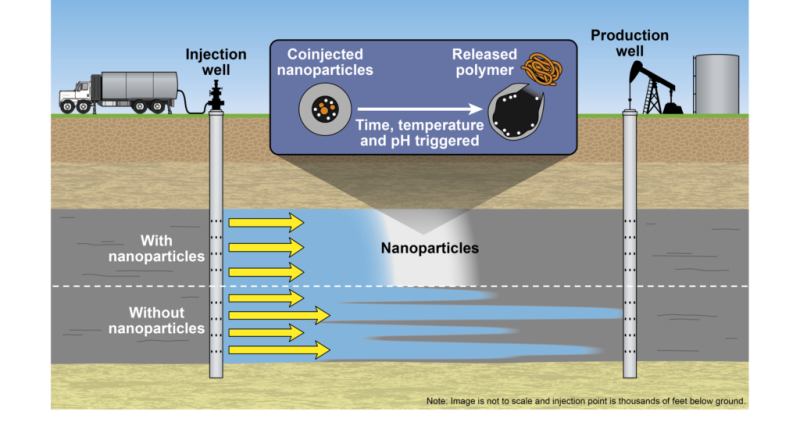

AEC is developing nanoreporters for the accurate determination of saturated oil remaining (SOR) in the reservoir. The challenge is to design stable and mobile nanoparticles with adequate specificity that can discriminate SOR at distinct locations in the reservoir. To address this challenge, we have designed stable, nanopayload delivery systems (Johnson et al. 2015) that have several unique features: (1) shielding of the cargo with a protective capsule to reduce nonspecific adsorption to reservoir rock, (2) trigger release by reservoir stimuli, (3) the addition of chemical clocking to enable release of cargo at discrete locations in the interwell space, and (4) ability to encapsulate multiple cargos in distinct compartments in core/shell structure.

Another application that can benefit from payload delivery is waterflood conformance control, where a low-viscosity nanomaterial is coinjected with the waterflood and will travel through the highest permeability regions (Fig. 3). Activated by designed triggers, the payload system will burst to release expandable polymers and crosslinkers to create a plug, diverting water to less-permeable areas of the reservoir resulting in increased sweep efficiency in waterflood applications.

Nanohybrid EOR Surfactant Flood

Each of the functional components of the nanosensor described above has its unique benefits that may make it suitable for various oilfield applications. For example, the polymer coatings required to mobilize the nanosensor package must have low adsorption under high-temperature salinity environments, a common challenge when designing suitable surfactants for EOR (ShamsiJazeyi et al. 2014). Therefore, we are assessing a number of our nanohybrids—nanoparticles coated with suitable polymeric or surfactant tails—for their ability to reduce interfacial tension (IFT) at the oil/water interface and improve EOR surfactant floods (Fig. 4). We have already designed nanohybrid systems that can tolerate significantly more salt and higher temperature than typical surfactants and have demonstrated ultralow IFT.

Smart Sand Microelectronic Sensors

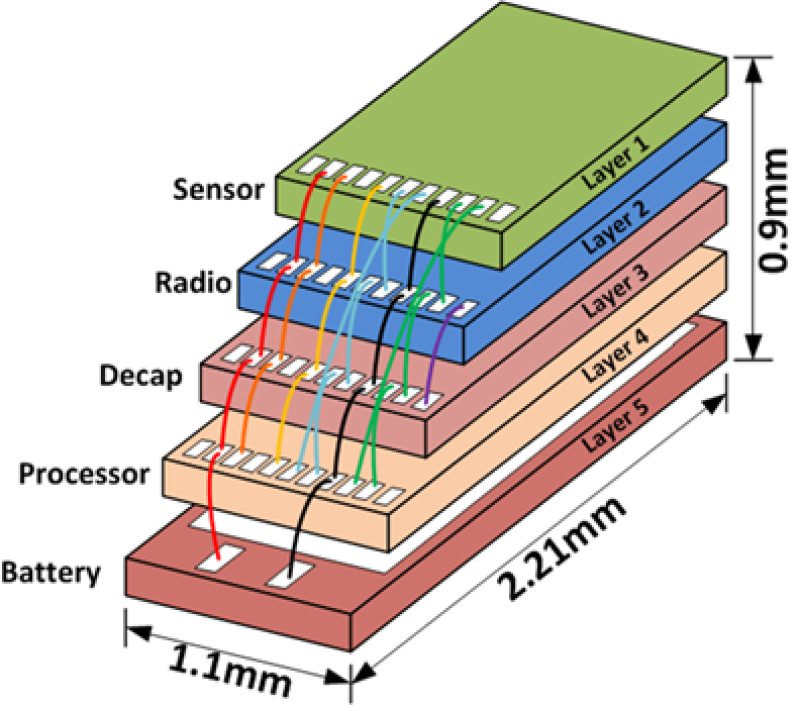

The AEC is developing subsurface autonomous nanosensor devices, or smart sand microelectronic sensors, that are tagged with time and geolocation and capable of acquiring measurements in harsh subsurface environments. The current data loggers (level sensors) are millimeter-scale system in a package (SiP), suitable for characterization of temperature, pressure, resistivity, and hydrocarbon concentration and usable in a number of applications including flow assurance, wellbore integrity, hydraulic fracture, and reservoir characterization (Fig. 5a). In addition to the onboard nanosensor, the electronic packaged device includes proprietary battery and memory to enable thousands of measurements over prolonged time periods. Because of the stacked-chip SiP design of the AEC smart sand, different sensor, power, microprocessor, communications, and/or packaging technologies can now be quickly incorporated into a prototype. The best-performing technologies can be incorporated into existing downhole tools or selected for further miniaturization (Chapman and Walt 2015) (Fig. 5b).

Fig. 5—The AEC’s 3-mm smart sand integrates sensing elements with supporting electronics, communications, proprietary power source, and protective packaging.

The initial platform development included 8-mm and 3-mm physical sensors (temperature and pressure) capable of operating at 7,500 psi and 125°C. Sensors that measure physical reservoir properties have the advantage of not needing to extend beyond the system’s outer harsh environment protective shell (packaging). We have successfully demonstrated the temperature sensors’ functionality in API brine and Isopar-L at elevated temperatures and pressures.

Summary

The AEC members’ funding of a research consortium has enabled the multidisciplinary research projects necessary to accelerate new opportunities for upstream exploration and production improvements as well as the necessary cross-functional industry knowledge. Each application listed above fits into key business areas of AEC members: waterflooding, hydraulic fracturing, EOR, well integrity monitoring, and reservoir characterization.

The applications, if successful, will give members a key advantage over competitors when it comes to recovering oil and natural gas. Significant progress has been made in many areas of research and development for enabling nanotechnology solutions and sensors for measurements under harsh subsurface conditions. Plans are under way to demonstrate the contrast agent mapping concepts in large pilot studies for hydraulic fracturing, waterflooding, EOR, and interwell reservoir characterization applications.

Acknowledgements

This article was supported by the Advanced Energy Consortium: http://www.beg.utexas.edu/aec/. Member companies include BP America, Petrobras, Repsol, Schlumberger, Shell, Statoil, and Total. Publication authorized by the director of the Bureau of Economic Geology.

References

Chapman, D. and Walt, T. 2015. SPIE Defense + Security Conference, International Society for Optics and Photonics, Baltimore, Maryland, USA, 20–24 April.

Johnson, K. 2010. Advances in Nanotechnology Hold Huge Potential Promise in Upstream Applications. The American Oil and Gas Reporter. July:112–123.

Johnson, L. M., Ledet, E., Huffman, N.D. et al. 2015. Controlled Degradation of Disulfide-Based Epoxy Thermosets for Extreme Environments. Polymer 64: 84–92.

LaBrecque, D., Brigham, R., Denison, J. et al. 2016. Remote Imaging of Proppants in Hydraulic Fracture Networks Using Electromagnetic Methods: Results of Small-Scale Field Experiments. SPE Hydraulic Fracturing Technology Conference, The Woodlands, Texas, USA, 9–11 February.

Rahmani, A.R., Bryant, S., Huh, C. et al. 2015. Characterizing Reservoir Heterogeneities Using Magnetic Nanoparticles. SPE Reservoir Simulation Symposium, Houston, Texas, USA, 23–25 February.

ShamsiJazeyi, H., Miller, C.A., Wong, M.S. et al. 2014. Polymer‐Coated Nanoparticles for Enhanced Oil Recovery. Journal of Applied Polymer Science. 131 (15).

Mohsen Ahmadian is a project manager and scientist at the Bureau of Economic Geology at the University of Texas/Austin. Drawing on more than 20 years of experience in nanotechnology, semiconductor, and biotech industries, he has been in charge of managing two portfolios of nanosensor research programs for the Advanced Energy Consortium (AEC) since 2010. These portfolios have been focused on synthesis and characterization of passive, active, or reactive nano- and micron-size particles as contrast agents or sensors with either selective oil-seeking properties for enhanced oil recovery or for the remote "illumination" of resources in subsurface reservoirs. He has also been leading the technology demonstration for three application development efforts for the AEC, including a large-scale pilot test for hydraulic fracture mapping with electromagnetic contrast agents.

David Chapman is a material science engineer. He has worked for Intel, Motorola, and the Research Triangle Institute. He manages microfabricated sensor research projects at the AEC.

Carla Nelson-Thomas is a chemist. She is a project manager with 11 years’ industry/management experience, including at Massachusetts Institute of Technology Lincoln Laboratory.

Jay Kipper is associate director of the BEG and the AEC. He is a chemical engineer and has worked in the energy industry for more than 25 years.

Scott Tinker is director of the BEG and the AEC. He is also the state geologist of Texas. He worked in the energy industry for 17 years before joining the BEG in 2000.